Apparel Packaging is crucial for presenting your brand’s image and protecting garments from manufacturer to customer. At UGI Packaging, we offer a complete catalog of custom solutions designed to meet the high standards of boutique fashion houses and major retail chains globally. Whether you require premium rigid boxes, clear vinyl display packaging, or custom-printed shopping bags, our comprehensive wholesale services ensure timely delivery, competitive pricing, and impeccable quality that truly elevates your product.

📢 Notice:

🖱 Hover your mouse over the image to see a “+” icon. Click it to zoom in and view the details! 🔍

Whether you need packaging solutions for garments like ties, shirts, gloves, footwear, or fur coats, UGI Packaging is ready to deliver. We produce custom apparel packaging for boutique fashion brands as well as major retail chains nationwide. Our goal is to provide premium packaging at competitive prices, ensure timely delivery, and achieve complete customer satisfaction.

UGI Packaging offers a wide range of items, including:

- Shoe boxes, tie boxes, shirt boxes

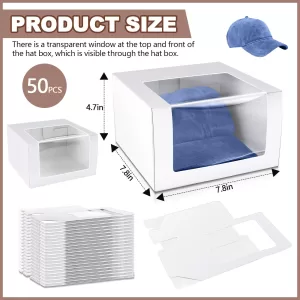

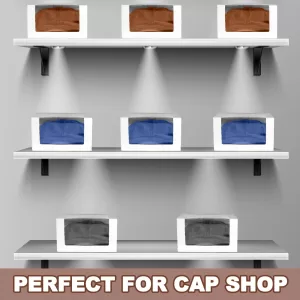

- Scarf & glove gift box, hat boxes

- Garment and lingerie boxes, underwear boxes

- Custom shopping bags, branded apparel gift bags

- Chipboard apparel boxes

- Clear apparel boxes

- Pillow-style boxes

- Recycled nature kraft apparel boxes

- High gloss 2 piece apparel boxes

- Matte apparel boxes

- Alligator apparel boxes

- Apparel gift box accessories, and many more…

CUSTOM APPAREL PACKAGING SERVICE

Whether you’re seeking apparel packaging for garments of various sizes, we offer a comprehensive range of boxes and bags tailored to your specific needs. From small accessories to larger clothing items, we provide packaging solutions designed to protect and present your products with style.

Our apparel packaging covers boxes and bags for shirts, trousers, ties, shoes, undergarments, and fashion accessories. Each item can be fully customized based on your brand requirements. A refined finish plays a crucial role—elevating the visual appeal and perceived value of the packaging.

Many of our boxes feature transparent windows (PVC or PET) for a clear view of the contents, adding a modern, premium touch. Enhance your brand presence with custom-printed apparel boxes that highlight your logo or unique artwork—perfect for attracting attention and building customer loyalty.

We offer full-color printing at competitive wholesale prices, with complete flexibility in materials, dimensions, and box types. Options include UV-resistant coatings, glossy or matte laminations, and moisture-resistant finishes—ensuring durability and a polished appearance.

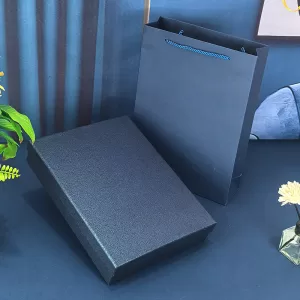

Apparel Gift Bags & Boxes

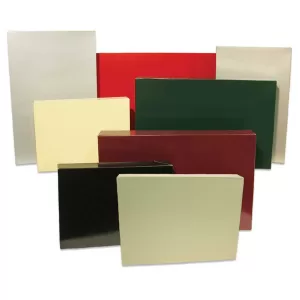

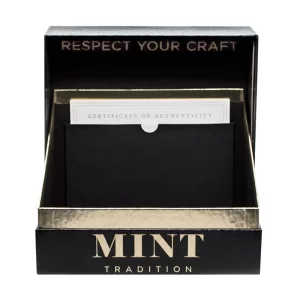

Chipboard Apparel Boxes

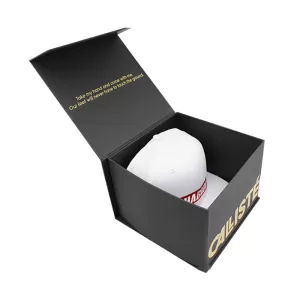

Rigid or set-up chipboard boxes – also known as paperboard boxes – are a premium packaging choice. These sturdy, non-collapsible boxes are ideal for luxury clothing and make a lasting first impression with their elegant construction.

At UGI Packaging, we specialize in crafting custom chipboard apparel boxes that blend durability with visual sophistication. You can choose from a wide selection of finishes, including matte or gloss solid colors, patterned or textured papers, foil-wrapped surfaces, or even fabric coverings. Your logo or artwork can be printed or foil stamped to create a packaging style that reflects your brand identity.

As a custom packaging manufacturer, UGI Packaging offers nearly endless possibilities. Get in touch with our team to explore all available options and design a unique apparel box that enhances your brand presence and elevates your customer experience.

Set-up boxes are strong, high quality, and labor friendly packages that require no tooling to manufacture. Strong set-up boxes also add aftermarket value to your product. When you add your logo or contact information to your set-up box, you’re creating a sales tool. Because of your set-up box’s strength and durability, your customers may save your set-up box to protect your product or to store other items.

Because set-up boxes ship to you already assembled, you will save the labor cost associated with other styles of packages because NO assembly is required. However, the set-up boxes can take up valuable cargo & warehouse space.

There is no tooling required to manufacture set-up boxes. No tooling costs make set-up boxes ideal for small volume or urgent orders. If you are test marketing your product and don’t want to pay hundreds or even thousands of dollars for the cutting dies required to make other styles of custom packaging, then set-up boxes are the perfect solution. No tooling also equals flexibility. Changing the size of your set-up box on a re-run will not require additional tooling costs.

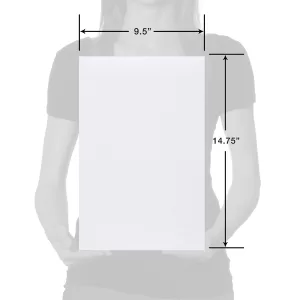

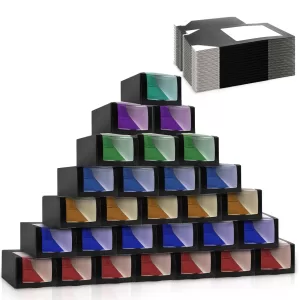

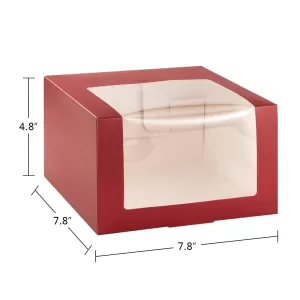

CLEAR APPAREL BOXES

UGI Packaging offers premium vinyl packaging solutions, also known as PVC boxes or clear two-piece boxes—an excellent option for presenting apparel in a refined, eye-catching way. These transparent boxes enhance product visibility while adding a sleek, modern touch that helps your garments stand out. As a custom vinyl box manufacturer, UGI Packaging can tailor each box to the precise dimensions of your apparel, ensuring a perfect fit and professional presentation.

Vinyl boxes offer a premium appearance at a budget-friendly cost, making them an excellent option for upscale apparel packaging. One popular style produced by UGI Packaging features a transparent top and bottom, allowing your product to remain fully visible and speak for itself on the shelf.

Another variation crafted by UGI Packaging combines a sturdy chipboard base wrapped in paper with a clear vinyl lid. This hybrid design not only enhances strength but also provides additional space for branding and printed graphics on the base, delivering both durability and visual appeal.

Vinyl boxes are premium-quality, user-friendly packaging solutions that eliminate the need for complex tooling during production. Ideal for a broad range of items—from fine glassware to artisanal confections—these boxes not only provide excellent protection but also showcase products in a way few other packaging styles can. Their high-end clarity and structure subtly suggest product quality, helping customers associate your goods with superior value.

Since vinyl boxes arrive pre-assembled, they reduce labor time and handling costs—no folding or setup is required. However, this convenience may require additional storage or shipping space due to their fully formed structure.

To further enhance your vinyl packaging, custom graphics or foil stamping can be applied for a refined and premium look. Foil stamping creates a vivid finish that outshines traditional printing and comes in matte, glossy, metallic, and holographic options. It adds elegance, reinforces branding, delivers product messaging, and helps your packaging stand out in the market—all for a minimal upgrade cost. Instead of settling for a plain container, turn it into a branded, high-impact display package.

PAPER BAGS & CARRIERS

UGI Packaging offers a diverse selection of custom printed paper bags, eco-conscious carriers, and branded retail packaging, shipped globally. Our client base includes boutique apparel brands, large-scale fashion retailers, and promotional firms. With our customizable solutions, we help businesses present their products attractively while maintaining sustainability and brand consistency.

We provide not only packaging products, but also complete, end-to-end solutions—making UGI Packaging your ideal one-stop partner for design, printing, and production. All services including design layout, print work, and finishing are carried out in-house at our own facility, ensuring consistent quality and fast turnaround times. Our experienced team is committed to delivering outstanding customer service, helping you bring your vision to life at highly competitive prices. From concept development to final delivery, we’re here to support your packaging needs and help your brand stand out every time a customer leaves your store.

Paper Bags & Sacks

Choose from a variety of styles such as block bottom bags, pink or blue striped designs, white and brown Kraft paper bags, clearface and cellophane bags, grease-resistant packaging, sulphite paper bags, and multiple paper sack sizes to suit your needs.

Polythene Bags, Rolls & Sacks

We supply polythene bags ranging from 90 to 500 gauge, lay-flat tubing on rolls, heavy-duty sacks for aggregate use, black refuse sacks, wheelie bin liners, pedal bin bags, and heat-sealable plastic bags.

Specialty Plastic Packaging

Our selection includes resealable poly bags, vacuum-seal pouches, LP record sleeves, and custom-printed poly mailers.

Paper & Polythene Carriers

Available in a wide range of sizes and colors, our carriers come with twisted or flat handles for retail and takeaway use.

High-Density Polythene (HDPE) Options

Including sheets, bags, and carrier rolls—perfect for high-volume or industrial applications.

Paperboard & Sheet Materials

We offer paper rolls, corrugated board reels, Kraft wrapping sheets, tissue paper, and greaseproof options.

Shipping & General Packaging Supplies

Including padded mailers, postal tubes with end plugs, document wallets, twines, strapping materials, sealing tapes, and stretch film.

Protective Packaging Solutions

Bubble wrap rolls, foam corners and edge guards, cellophane film rolls, polystyrene fillers, and more to keep products safe in transit.

Dispensing Tools

We also supply tape dispensers and tape guns to streamline your packing process.

Let UGI Packaging support your business with reliable, customized packaging tailored to your brand and operational goals.

| By Special Features | By Material Type |

|---|---|

| Luxury Paper Gift Bags | Medium Matt Paper Bags with Die-Cut & Ribbon Seal |

| Gift Bags with Twisted Paper Handles | Medium Matt Paper Bags with Round Die-Cut |

| Gift Bags with Flat Tape Handles | Animal Print Paper Bags |

| Small Gloss Rope Handle Paper Bags | Cotton Bags |

| Small Matt Rope Handle Paper Bags | Non Woven Bags |

| Small Gloss Paper Bags with Rope Handles | Jute Shopping Bags |

| Medium Gloss Rope Handle Paper Bags | Small Kraft Twisted Handle Paper Bags |

| Medium Matt Rope Handle Paper Bags | Medium Kraft Twisted Handle Paper Bags |

| Small Matt Paper Bags with Rope Handles | Large Kraft Twisted Handle Paper Bags |

| Large Gloss Rope Handle Paper Bags | Extra Large Twisted Paper Handle Bags |

| Large Matt Rope Handle Paper Bags | Medium Kraft Flat Tape Paper Bags |

| Pyramid Bags with Ribbon Handles | Small Kraft Flat Tape Paper Bags |

| Window Gift Bags | Woven Bags |

| Gift Bags with Ribbon Handles | Plastic bags |

| Shopping & Promotional Bags | Organza Bags |

Customer satisfaction is UGI number one priority! Everyone at UGI is proud of the company’s solid reputation which is founded on a combination of traditional service, superb product quality, and the total commitment that is necessary to maintain accuracy at every stage of production. Existing customers remain confident in our abilities to look after their requirements and return to us each time they need to reorder. New customers receive exactly the same level of service because we know a successful business is totally dependent on the absolute satisfaction of all its clients.

Showcases

Our wholesale apparel boxes are essential for fashion retailers, especially when wrapping gifts quickly and beautifully at the checkout counter. Catering to a variety of retail and gift-giving needs, we provide an extensive selection of sizes, shapes, and colors perfectly suited for packaging clothing items.

Features & Materials

- Available in popular stock colors like black, white, and kraft, as well as customizable hues with matte or glossy finishes.

- Eco-conscious construction using mostly post-consumer recycled paperboard and water-based inks.

- Size options range from small tie boxes to large shirt boxes and even oversized boxes designed for sweaters, coats, and robes.

- Packaging styles include classic two-piece pop-up designs, folding top tuck boxes, and rigid setup boxes.

- The two-piece pop-up boxes consist of two matching pieces that fold flat for storage and pop open for use—ideal for shirts.

- Alternative options include pillow-style boxes and magnetic closure boxes for added elegance.

- Rigid boxes are crafted from preformed chipboard for durability.

- Proudly made in the USA and fully recyclable.

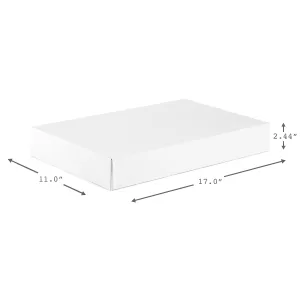

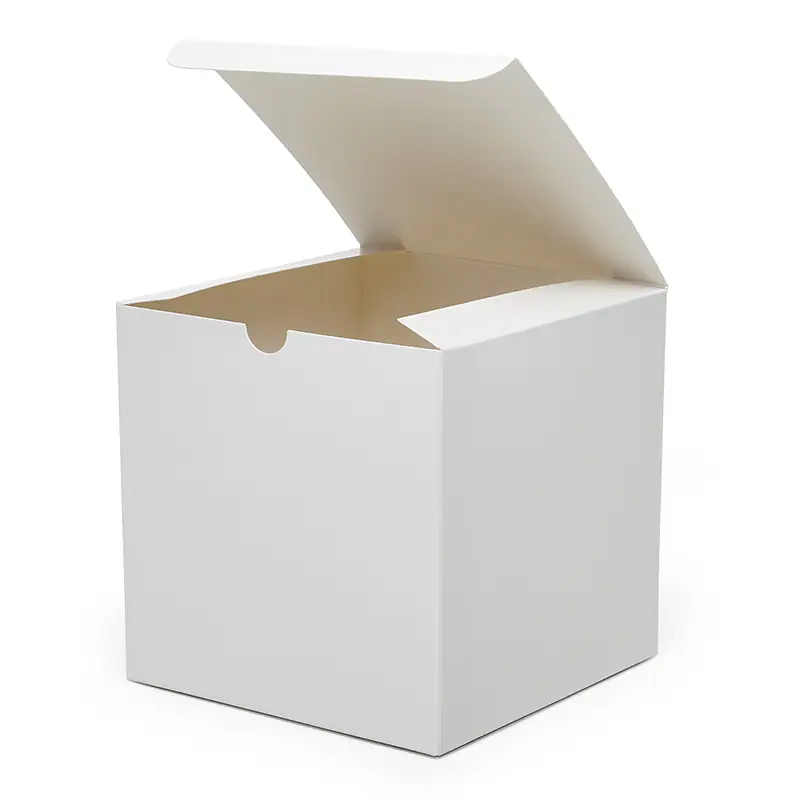

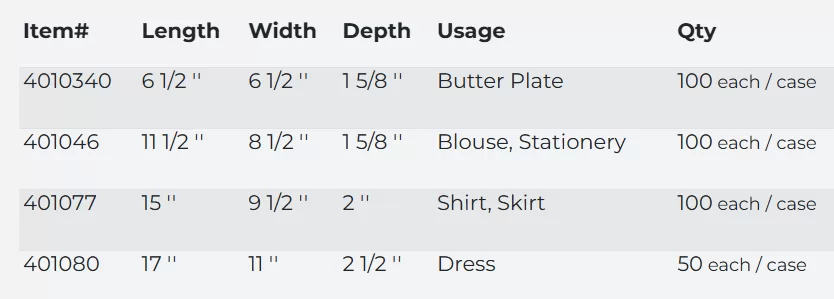

Apparel Boxes

Our White and Natural Kraft Apparel Boxes are an excellent choice for retail stores offering gift-wrapping services or stylish packaging solutions. These two-piece folding pop-up boxes are available in a variety of sizes—including generous coat-size options—and are offered in either a sleek Gloss White Frost finish or a textured Recycled Natural Kraft Groove design. Crafted with sustainability in mind, these boxes are made from 100% recycled materials. The Kraft boxes are fully post-consumer recycled, while the White boxes contain 80–100% post-consumer fibers. The interior of the White boxes features an unbleached white tone, which may vary slightly to a soft gray, while the Kraft boxes showcase a natural brown interior with subtle variations in shade.

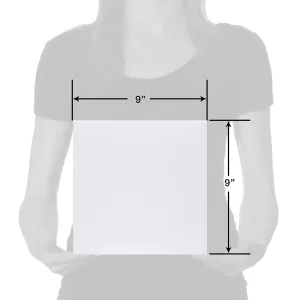

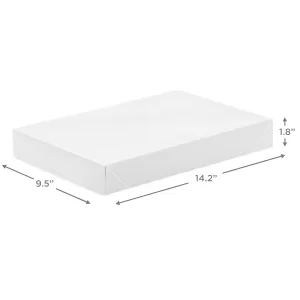

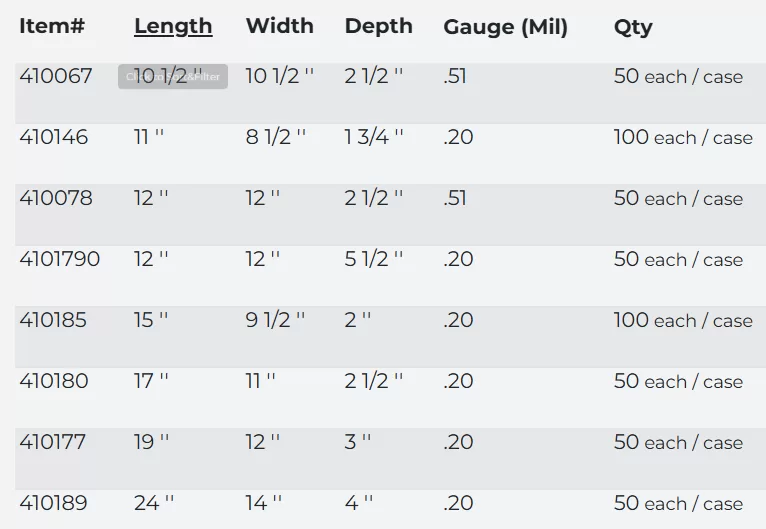

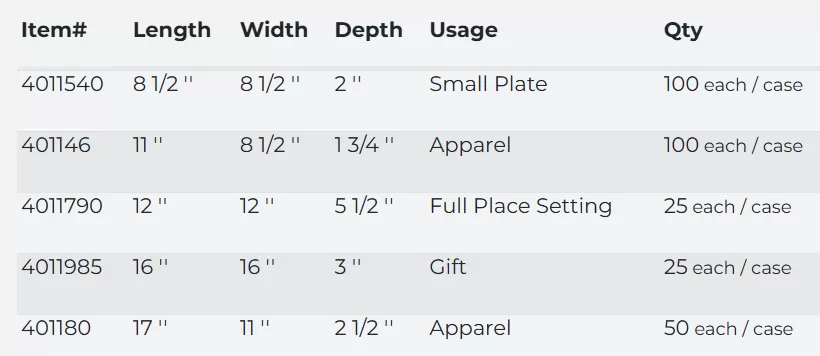

Standard Sized Apparel Boxes in Stock

Build your gift wrap inventory with our wide selection of in-stock apparel boxes – perfect for packaging T-shirts, scarves, ties, pants, small accessories, and more. Whether it’s for birthdays, holidays, graduations, or everyday gift-giving, our boxes offer a polished, professional look that elevates your presentation. We offer a full range of apparel gift boxes in various sizes and structural designs, including pop-up folding boxes, rigid setup boxes, and tuck-top styles. Each box is made for durability, ease of use, and elegant display—ideal for retail stores, packaging services, and event planners. Why Choose Us?

- Ready-to-Ship Inventory: We maintain a large stock of popular sizes and styles to ensure fast order fulfillment.

- Quick Delivery: Standard items can be shipped promptly, helping you meet tight schedules or urgent retail needs.

- Made in China: Manufactured with precision and cost efficiency under strict quality control.

- Competitive Wholesale Pricing: Affordable rates with consistent product quality.

- Custom Options Available: Add your brand’s logo or choose from special finishes with low minimum order quantities.

Pair your boxes with our coordinating gift bags to create a cohesive packaging solution that’s both stylish and functional. Whether you’re preparing seasonal packaging or need reliable day-to-day retail supplies, our apparel boxes deliver quality, speed, and value.

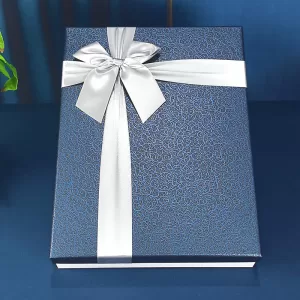

Apparel Gift Box Accessories

Complete Your Apparel Gift Box with Raffia Paper and Ribbon Finishing Touches – enhance the unboxing experience of your apparel gift packaging with elegant finishing details. Pairing your gift boxes with raffia paper and decorative ribbon adds texture, color, and a sense of luxury—making every package feel more thoughtful and refined.

- Raffia Paper is perfect for filling space and protecting delicate garments while adding a natural, eco-friendly touch. Its lightweight, shredded texture creates a soft nest for items like scarves, shirts, or accessories, helping elevate the overall presentation.

- Ribbons can be tied around the box or used inside for added charm. Choose from satin, grosgrain, or custom-printed ribbons in colors that match your brand or seasonal themes. A simple bow can instantly transform a box into a high-end gift.

These packaging accents not only improve visual appeal but also increase perceived value—ideal for boutique retailers, gift shops, online sellers, and special event packaging. Whether you’re creating custom gift sets or premium retail packaging, raffia and ribbon are the perfect final touches.

Recycled Nature Kraft Apparel Boxes

These two-piece boxes feature a natural kraft exterior enhanced with a deep dye tint, offering a rustic, organic appearance. Each set includes a sturdy base and a full-coverage lid. The exterior is fully colored, while the interior remains kraft brown for a clean, natural contrast. Designed as semi-automatic pop-up boxes, they’re easy to assemble and ideal for use as complimentary packaging for retail and customer giveaways. Boxes are shipped flat for efficient storage and quick assembly at the point of use.

Please Note on Sizing:

- Length refers to the widest opening of the box

- Width is the narrower opening side

- Depth is measured from the top opening to the bottom interior

All dimensions are listed as exterior measurements.

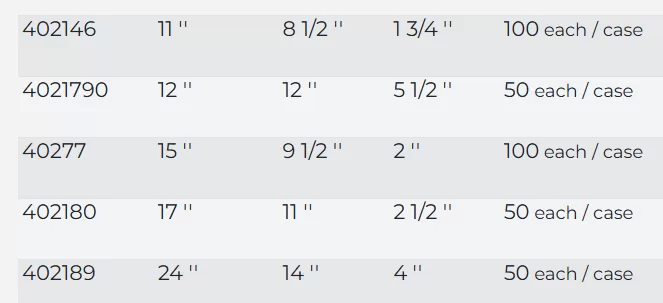

High Gloss Two Piece Apparel Boxes

Add a vibrant touch to your retail packaging with our color pop-up apparel boxes—designed to coordinate seamlessly with our paper shopping bags for a cohesive and stylish presentation. These two-piece pop-up boxes feature a glossy finish in a variety of rich colors, creating an eye-catching store box that enhances your brand identity.

Perfect for packaging shirts, ties, pants, and fashion accessories. The boxes ship flat for efficient storage and are made with sustainability in mind—our Kraft boxes are crafted from 100% post-consumer recycled materials, while our White boxes contain 80–100% post-consumer content.

Matte Apparel Boxes

Offered in a range of vibrant colors and versatile sizes, our color pop-up apparel boxes pair perfectly with our coordinating paper shopping bags—creating a polished, unified packaging experience. Several matte finish colors are available in stock, while over 30 custom colors can be made to order to suit your brand’s unique style.

Ideal for packaging shirts, ties, trousers, and clothing accessories. These two-piece boxes ship flat for convenient storage and are crafted from 100% recycled materials. Our Kraft boxes are made entirely from post-consumer content, while our White boxes contain 80–100% post-consumer fibers. Stock and custom color options are available to meet your packaging needs with style and sustainability.

Alligator Apparel Boxes

Store and present your products in style with these two-piece apparel boxes, designed for packaging lightweight items with a touch of luxury. Featuring a white alligator-embossed exterior and a solid-colored interior, these boxes offer both elegance and functionality. The wide, flat lid fully overlaps the base, ensuring complete coverage and a polished look—perfect for retail displays, product storage, or stylish gift-giving.

Box Dimensions Guide:

- Length: The widest side of the box opening

- Width: The narrower side of the box opening

- Depth: The vertical measurement from the opening to the bottom of the box

These boxes combine elegant presentation with practical design—ideal for upscale apparel packaging.

Assembly Made Simple:

Boxes ship flat for convenient storage. To assemble, lift the side panels of the base and allow the corner tabs to pop into place, forming sturdy walls. Repeat the process for the lid. Once assembled, place your items inside the base and close with the overlapping lid for a clean, secure finish.

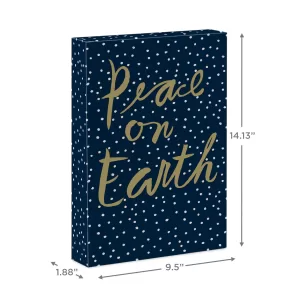

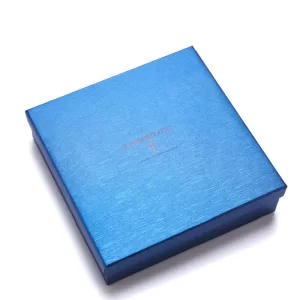

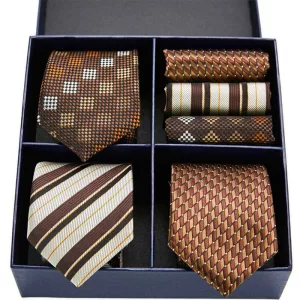

Necktie Gift Boxes

Designed specifically for luxury men’s boutiques and haberdasheries, these Necktie Gift Boxes offer an elegant and striking way to present classic neckties to your customers or gift recipients. Elevate the gifting experience with these sophisticated boxes that add an upscale touch to any men’s neckwear.

Crafted in a rigid setup style, these boxes require no assembly and provide sturdy protection. Dimensions are listed as Length x Width x Height. Made from 100% recycled materials, our Kraft boxes are fully post-consumer recycled, while our white boxes contain between 80% and 100% post-consumer fibers. Boxes are sold in cases for convenience.

Additional Details:

- Perfect for creating a premium presentation for men’s neckties.

- Rigid box construction means no assembly is needed.

- Interior colors vary by box type: white boxes feature an unbleached white interior (which may sometimes appear slightly gray), while Kraft boxes have a natural Kraft-colored interior—a light, varying shade of brown.

- Made in the Guangzhou, China.

- Environmentally friendly, using 100% recycled materials; Kraft boxes are fully post-consumer recycled, white boxes contain 80-100% post-consumer fibers.

- Material: Paper.

Hat Boxes

Our Hat Boxes are an essential packaging solution for retailers, e-commerce shops, and individuals looking to store or present hats and other large items with style. These two-piece folding boxes feature a convenient cord handle and are available in a range of sizes, including a spacious 18″ x 18″ x 7″ option. The soft grey interior adds a clean, classic finish for a polished and professional presentation.

Key Features:

- Ideal for use as retail hat boxes or for storing oversized items.

- Suitable for physical retail stores, online shops, or personal use.

- Constructed in the USA from high-quality paper for strength and durability.

- Two-piece design folds flat for space-saving storage when not in use.

- Includes a sturdy cord handle for easy carrying and display.

Additional Details:

- Interior Color: Grey

- Made In: Guangzhou China

- Eco-Friendly: Crafted from paper with sustainability in mind

- Material: Paper

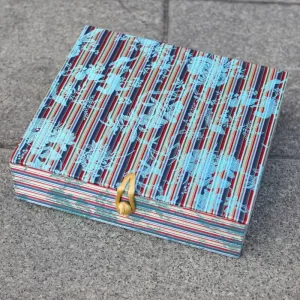

Scarf & Glove Gift Box

At UGI Packaging, we specialize in providing premium scarf and glove gift boxes designed to elevate your product presentation and enhance the gifting experience. Whether you’re a fashion retailer, accessories brand, or event organizer, our packaging solutions offer the perfect combination of functionality, elegance, and customization. Perfect for:

- Retail packaging for premium scarves, shawls, or pashminas

- Seasonal gift sets (Christmas, Mother’s Day, Valentine’s Day)

- Corporate gifting and brand promotions

- Boutique and e-commerce apparel brands

Custom Apparel Gift Box Solutions – Tailored for Your Brand

Elevate your brand presentation with our fully customizable apparel gift boxes. Whether you’re packaging shirts, dresses, scarves, or fashion accessories, our custom box service allows you to create packaging that reflects your brand’s identity and enhances the unboxing experience.

Choose from a wide range of sizes, materials, textures, and finishes—including matte, gloss, kraft, embossed, and specialty patterns like alligator or linen textures. Add your logo through foil stamping, spot UV, or full-color printing for a professional and polished look.

We offer low minimum order quantities and flexible production timelines, with structural and design support available to guide you from concept to final product. Whether you’re a boutique, retailer, or event planner, our custom apparel boxes are the perfect solution to make your packaging as stylish as the clothing inside.

Minimum order starts at 500 boxes. Mixed sizes allowed. Contact us for a quote today.

Product Catalog in Video Format

We present our apparel packaging collection through a video product catalog, highlighting each item’s design, materials, and functional details. This immersive format allows you to experience the quality, craftsmanship, and brand-enhancing features of our packaging in action, making it easier to choose the right solutions for clothing, accessories, and retail presentation needs.

We are a professional China-based manufacturer specializing in apparel packaging, offering a wide range of custom solutions including garment boxes, paper bags, and hang tags. As a direct factory, we provide significant price advantages without compromising on quality. With advanced equipment, skilled craftsmanship, and fast turnaround times, we help brands enhance their packaging appeal while keeping costs competitive. Ideal for retail, e-commerce, and promotional use.

- Widely used by retail stores offering men’s, women’s, and children’s apparel.

- Perfect for gifting clothing such as shirts, dresses, pants, and outerwear.

- Easy for both retailers and customers to assemble quickly.

- Can be wrapped in decorative paper or used as-is with vibrant colors and ribbons for effortless gift presentation.

- Ideal for special occasions like Father’s Day, Valentine’s Day, bridal showers, and weddings.

- Custom color options available for branding purposes with a minimum order of 500 boxes.

- Enhance brand visibility by printing your logo via foil stamping, ink, or digital printing.

- Robust construction ensures these boxes can be reused for future gift-giving occasions.

📢 Get in Touch Today!

Let’s create something extraordinary together. Contact us for samples or partnership opportunities!

As a professional packaging factory in Guangzhou, China, we offer fully customized gift boxes & bags tailored to your branding needs. We can create the perfect solution to elevate your packaging. Let us know your product type, and we’ll recommend the best options!

📞 Contact Us for a Free Quote

Email: [[email protected]]

Website: [ukugi.com/show]

WhatsApp: [ +44 7783 771295]

Call to speak with one of our experts to get more details about our custom packaging offerings, and a dieline template for your packaging:

Let’s talk

Our WhatsApp is online 24/7.

If you have any questions, you can contact our customer service at any time.

UGI Packaging & THE ENVIRONMENT

UGI Packaging recommends using eco-conscious cloth carrier bags, biodegradable poly carriers, and 100% recycled paper bags – each customizable with your brand logo and marketing message. Choose from a wide selection of styles, finishes, and vibrant color options, all designed to enhance your brand presence and support your promotional efforts. Our expert design team and strict quality standards ensure your packaging is both impactful and reliable.

At UGI Packaging, we take our environmental responsibilities seriously. We’ve introduced several internal initiatives to reduce our ecological footprint and are committed to sustainable practices. Our growing line of eco-friendly packaging options reflects this commitment. Additionally, we power both our offices and manufacturing facility using renewable, sustainably sourced electricity.

Frequently Asked Questions about Apparel Packaging

📐 Chipboard GSM & Load-Bearing Relationship

Understanding GSM (Grams per Square Meter):

Chipboard thickness directly determines box strength and durability. For apparel packaging, selecting the correct GSM ensures your products arrive undamaged while optimizing material costs.

GSM Standards by Apparel Category:

600-1000 GSM: Lightweight Accessories

Ideal for: Ties, scarves, gloves, socks, belts

Load capacity: Up to 500g per box

Structural benefit: Sufficient rigidity for retail display without excess weight

Cost advantage: 25-35% cheaper than higher GSM options

1200-1500 GSM: Standard Garments

Ideal for: Shirts, blouses, dresses, light trousers

Load capacity: 500g-1.5kg per box

Structural benefit: Resists crushing during stacking (supports 5-8 boxes vertically)

Industry standard: Most fashion retailers use this range for general apparel

1800-2000 GSM: Heavy Apparel

Ideal for: Winter coats, leather jackets, denim, premium footwear packaging

Load capacity: 1.5kg-3kg per box

Structural benefit: Reinforced corners prevent bulging, maintains shape under weight

Premium positioning: Signals quality to luxury brand customers

🔬 Material Composition Standards

According to TAPPI (Technical Association of the Pulp and Paper Industry) guidelines, chipboard used in apparel packaging should meet:

Density consistency: ±5% variance across the sheet (prevents weak spots)

Moisture content: 6-8% for dimensional stability (critical in humid climates)

Burst strength: Minimum 300 kPa for 1500 GSM board (tested per ISO 2758 standard)

Pro Tip: For e-commerce shipping, add 200 GSM to your standard retail packaging spec. The extra rigidity compensates for rough handling during logistics. A Packaging Digest study found that 1500 GSM boxes reduce damage claims by 34% versus 1200 GSM in courier networks.

💰 Cost-Performance Balance

Real-world example: 10,000 shirt boxes

1200 GSM cost: $0.85/box

1500 GSM cost: $1.05/box (+24%)

1800 GSM cost: $1.35/box (+59%)

Damage reduction with 1500 GSM: Saves $0.30/box in returns

Net cost-effectiveness: 1500 GSM breaks even despite higher material cost

🔍 PVC vs PET: Material Comparison

Transparency Performance:

PVC (Polyvinyl Chloride) Boxes:

Light transmission: 88-92% (slightly hazy appearance)

Clarity: Good for general product visibility

Yellowing resistance: Moderate – begins after 12-18 months UV exposure

Best for: Short-term retail displays, indoor use

Cost: $0.40-$0.65 per box (budget-friendly)

PET (Polyethylene Terephthalate) Boxes:

Light transmission: 92-95% (crystal-clear)

Clarity: Excellent – showcases fine details (ideal for premium apparel)

UV resistance: Superior – maintains clarity for 3+ years

Best for: Long-term storage, window displays, luxury positioning

Cost: $0.60-$0.90 per box (+35-50% vs PVC)

💪 Durability & Environmental Impact

Structural Strength (Tested per ASTM D638):

PVC:

Tensile strength: 40-50 MPa

Impact resistance: Moderate – cracks at sharp bends

Temperature tolerance: Becomes brittle below 0°C

Scratch resistance: Low – visible scuffs from retail handling

PET:

Tensile strength: 55-75 MPa (+38% stronger)

Impact resistance: High – flex without cracking

Temperature tolerance: Stable from -40°C to 70°C

Scratch resistance: High – maintains appearance longer

♻️ Sustainability Considerations

According to the U.S. EPA recycling data:

PET recyclability: Code #1 plastic – widely accepted in curbside programs (94% of US municipalities)

PVC recyclability: Code #3 plastic – limited acceptance due to chlorine content (less than 10% recycling rate)

Environmental impact: PET production generates 30-40% fewer CO2 emissions than PVC

For EU/UK markets: PET complies with REACH regulations more easily. PVC requires specific phthalate-free certification (adds $0.08-$0.12 per box in compliance costs).

🎯 Application Recommendations

Choose PVC if:

Budget-constrained mass retail packaging

Product turnover under 6 months

Indoor-only display environments

Cost per unit is primary concern

Choose PET if:

Premium brand positioning essential

Products remain in packaging 6+ months

Window displays with direct sunlight exposure

Targeting eco-conscious consumers or EU markets

Pairing with luxury foldable magnetic boxes for hybrid packaging

Industry Insight: A Packaging Digest survey found that 68% of consumers perceive PET-packaged products as 15-20% more valuable than identical PVC packaging, justifying the cost premium for mid-luxury brands.

📦 Paper Bag GSM Selection Guide

GSM Standards for Apparel Retail:

80-100 GSM: Lightweight Accessories

Applications: Small items like socks, underwear, scarves

Load capacity: Up to 1kg

Handle type: Twisted paper or thin rope handles

Cost: $0.15-$0.25 per bag

Drawback: Tears easily if overfilled or exposed to moisture

Best for: In-store impulse purchases, small gift items

120-157 GSM: Standard Retail Bags

Applications: Shirts, blouses, light trousers, multiple small items

Load capacity: 2-3kg comfortably

Handle type: Flat tape or rope handles (reinforced attachment)

Cost: $0.30-$0.50 per bag

Durability: Withstands typical shopping trip without reinforcement

Industry standard: Most fashion retailers use 157 GSM kraft paper

View our complete gift bag collection

200-250 GSM: Premium Shopping Bags

Applications: Coats, jackets, jeans, shoes, multi-item purchases

Load capacity: 4-6kg

Handle type: Cotton webbing or thick rope handles

Cost: $0.60-$0.95 per bag

Luxury feature: Matte or glossy lamination resists water, enhances brand perception

Reusability: Customers keep and reuse = walking brand advertisement

300+ GSM: Ultra-Premium/Structural Bags

Applications: High-end boutiques, luxury brand flagship stores

Load capacity: 6-10kg

Handle type: Cotton ribbon or die-cut handles

Cost: $1.20-$2.50 per bag

Construction: Often includes rigid cardboard base and reinforced sides

Brand impact: Signals luxury tier (Chanel, Hermès use 350+ GSM)

🎨 Material Type Impact on Performance

Kraft Paper (Natural Brown):

Tensile strength: Highest among paper types (per USDA Forest Products Laboratory)

Eco-positioning: 100% recyclable, biodegradable within 6 months

Cost advantage: 15-20% cheaper than white/colored paper at same GSM

Aesthetic: Pairs with eco-conscious or artisanal brands

Coated Art Paper (White/Colored):

Printability: Superior color vibrancy for brand logos (CMYK prints pop)

Surface finish: Gloss or matte lamination available

Water resistance: Laminated bags handle light rain

Cost premium: +20-30% vs kraft, but better brand visibility

Non-Woven Polypropylene:

Not paper, but popular alternative: 70-100 GSM feels like heavy paper

Waterproof: Ideal for swimwear, activewear retail

Reusability: 50+ uses typical (study by WRAP UK)

Cost: $0.40-$0.70 per bag

Environmental note: Recyclable but not biodegradable

💡 Decision Framework

Fast Fashion / Budget Retail:

120-157 GSM kraft or white paper + twisted handles = $0.30-0.40 per bag

Mid-Market Apparel:

157-200 GSM white paper + matte lamination + flat tape handles = $0.50-0.70 per bag

Premium Boutiques:

250+ GSM coated paper + gloss lamination + cotton ribbon handles + custom foil stamping = $1.20-2.00 per bag

Real-World Test: Fill bag to intended capacity, lift by handles 50 times, drop from 1 meter twice. Bag should show no tearing or handle detachment. Per ISTA packaging guidelines, this simulates typical customer use.

✨ Surface Finishing & Brand Perception

1. Matte Lamination

Tactile experience: Soft-touch, velvety feel signals sophistication

Visual impact: Subdued elegance, reduces glare under retail lighting

Brand positioning: Modern luxury, minimalist aesthetics (think COS, Everlane)

Fingerprint resistance: Excellent – maintains pristine appearance

Cost impact: +$0.12-$0.18 per box vs uncoated

Best for: Premium casualwear, sustainable fashion brands, Scandinavian aesthetics

2. Glossy Lamination

Tactile experience: Smooth, slippery, high-shine finish

Visual impact: Vibrant color saturation (+35-40%), eye-catching on retail shelves

Brand positioning: Bold, youthful, energetic (think Zara, H&M)

Durability: Scratch-resistant, easy to wipe clean

Cost impact: +$0.10-$0.15 per box vs uncoated (slightly cheaper than matte)

Best for: Fast fashion, vibrant activewear, cosmetics-adjacent apparel

3. Embossing/Debossing

Tactile experience: 3D logo texture creates memorable touch-point (depth: 0.3-0.8mm)

Visual impact: Subtle luxury without color printing required

Brand positioning: Heritage luxury, established brands (Ralph Lauren aesthetic)

Durability: Permanent – won’t fade or wear like printing

Cost impact: +$0.25-$0.45 per box (requires custom die)

Setup fee: $150-$400 one-time tooling cost

Best for: Leather goods, tailored menswear, luxury lingerie

Pro tip: Combine with foil stamping for maximum impact (+$0.15-$0.25 additional)

4. Alligator/Crocodile Embossed Texture

Tactile experience: Distinctive reptilian pattern, premium tactile weight

Visual impact: Instant luxury recognition (mimics $5,000+ handbag materials)

Brand positioning: Accessible luxury, aspirational brands

Psychological effect: Journal of Business Research study found textured packaging increases perceived value by 18-23%

Cost impact: +$0.30-$0.55 per box vs smooth boxes

Best for: Handbag packaging, designer shoe boxes, luxury accessories

Challenge: Logo printing requires careful alignment with texture pattern

5. Linen/Canvas Texture

Tactile experience: Woven fabric appearance, natural feel

Visual impact: Eco-conscious aesthetic without sacrificing elegance

Brand positioning: Sustainable luxury, organic fashion brands

Cost impact: +$0.18-$0.28 per box

Best for: Organic cotton apparel, eco-friendly brands, resort wear

📊 Pricing Strategy Impact

Consumer Perception Study:

Research by Packaging of the World surveyed 2,500 consumers:

Uncoated chipboard box: Perceived product value baseline (100%)

Matte lamination: +22% perceived value increase

Glossy lamination: +15% perceived value increase

Embossed logo: +28% perceived value increase

Alligator texture: +35% perceived value increase

Emboss + foil stamping: +42% perceived value increase

Break-Even Analysis:

If your product retails for $80:

Basic box cost: $1.00 (1.25% of retail price)

Matte lamination box: $1.18 (+18%)

Customer willing to pay: $80 × 1.22 = $97.60

Net gain: $17.42 per unit from $0.18 packaging investment = 96:1 ROI

When to Upgrade Packaging:

Product margin >45%: Invest in premium finishes

Product margin 30-45%: Selective upgrades (emboss logo only)

Product margin <30%: Focus on branded paper bags instead of rigid boxes

🎯 Competitive Positioning

Fast Fashion Tier ($20-50 retail):

Glossy lamination + simple logo print = adequate brand expression

Contemporary Tier ($50-150 retail):

Matte lamination + spot UV logo or embossing = modern sophistication

Luxury Tier ($150-500 retail):

Alligator texture + blind emboss + gold foil = unmistakable premium

Ultra-Luxury Tier ($500+ retail):

Custom texture + multi-level emboss + metallic foil + fabric liner = art piece packaging

🌳 FSC Certification: Beyond Environmental Compliance

What is FSC (Forest Stewardship Council)?

FSC is an international non-profit that sets standards for responsible forest management. For B2B procurement, FSC certification proves your packaging paper comes from sustainably managed forests.

Three FSC Labels Explained:

FSC 100%:

Definition: All virgin fiber from FSC-certified forests

Cost premium: +12-18% vs non-certified

Market positioning: Premium eco-conscious brands

Best for: Luxury sustainable fashion targeting conscious consumers

FSC Mix:

Definition: Blend of FSC-certified + controlled wood sources

Typical ratio: 70% FSC certified, 30% controlled sources

Cost premium: +6-10% vs non-certified

Market positioning: Mainstream brands meeting sustainability goals

Best for: Mid-market retailers balancing cost and environmental responsibility

FSC Recycled:

Definition: 100% post-consumer or post-industrial recycled content

Cost: Often comparable to non-certified virgin material

Market positioning: Circular economy leaders

Best for: Brands with aggressive zero-waste commitments

Check our custom eco-friendly packaging options

📜 Regulatory & Market Access Requirements

European Union:

EU Deforestation Regulation (EUDR – effective 2024): Requires proof that packaging materials didn’t contribute to deforestation

FSC certification simplifies compliance (alternative: complex supply chain due diligence)

Non-compliance penalty: Products can be blocked at EU customs

Major retailers (H&M, Inditex) now mandate FSC certification from suppliers

United States:

Lacey Act: Prohibits trade in illegally sourced wood products

FSC certification provides legal safe harbor

California SB 270: Reusable bag standards favor FSC-certified paper

Corporate policies: Target, Walmart, Nordstrom prefer FSC suppliers (per Rainforest Alliance data)

United Kingdom:

UK Timber Regulation (UKTR): Mirrors EU requirements post-Brexit

Extended Producer Responsibility (EPR): FSC materials ease compliance reporting

♻️ Recycled Content Requirements

Post-Consumer Recycled (PCR) Content:

30-50% PCR:

Performance: Minimal difference from virgin material

Color: Slight off-white tint (acceptable for kraft aesthetic)

Cost: 5-8% cheaper than virgin fiber

Regulatory: Meets California AB 1201 minimum standards

80-100% PCR:

Performance: May show minor fiber inconsistencies (not visible under lamination)

Color: Noticeably grayer (works for rustic or eco-positioned brands)

Cost: 10-15% cheaper than virgin fiber

Marketing value: Strongest environmental claim

Certification: Often eligible for FSC Recycled label

📊 B2B Procurement Decision Factors

1. Customer ESG Reporting Requirements:

Your clients (fashion brands) must report Scope 3 emissions (supply chain). FSC-certified packaging helps them meet targets:

FSC-certified paperboard: ~40% lower carbon footprint vs non-certified (per Environmental Paper Network)

Brands can directly attribute your FSC materials to their sustainability reports

Competitive advantage: 73% of fashion brands now require supplier ESG documentation

2. Consumer Demand Trends:

McKinsey & Company survey: 67% of consumers consider sustainability when purchasing apparel

Visible FSC logo on packaging increases purchase intent by 12-18% (Nielsen study)

Premium brands using FSC packaging command 8-15% price premium without consumer resistance

3. Retail Partnership Requirements:

Major department stores (Selfridges, Bloomingdale’s) now mandate FSC-certified packaging for new vendors

Online marketplaces (Farfetch, Net-a-Porter) highlight FSC compliance in supplier scorecards

Non-compliant packaging can disqualify brands from shelf space

💰 Cost-Benefit Reality Check

Scenario: 50,000 apparel boxes annually

Standard non-certified chipboard:

Cost: $1.00/box = $50,000 total

Risk: Potential non-compliance with EU/US regulations

Market access: Limited to non-regulated markets

FSC Mix certified chipboard:

Cost: $1.08/box = $54,000 total (+$4,000 annually)

Benefits: Full EU/US market access

Qualifies for major retail partnerships

Client can use for ESG reporting

Marketing differentiation

ROI: Single retained client contract ($150k+ value) justifies certification investment

100% PCR FSC Recycled:

Cost: $0.92/box = $46,000 total (SAVES $4,000)

Benefits: All FSC Mix benefits PLUS cost savings

Trade-off: Slightly less pristine appearance (mitigated with lamination)

Best value for eco-conscious brands not requiring pure white boxes

🎯 Procurement Recommendation Framework

Luxury/Premium Brands:

FSC 100% virgin fiber + matte lamination = pristine appearance + environmental credentials

Mid-Market Brands:

FSC Mix (70/30) = balanced cost and certification

Eco-Focused/DTC Brands:

FSC Recycled 100% PCR = strongest environmental story + cost savings

Fast Fashion/Budget:

FSC Mix minimum to maintain regulatory compliance and retail partnerships

Critical Note: Always request FSC chain-of-custody certificates from suppliers. Verify certification code at FSC database. Uncertified suppliers claiming “FSC-equivalent” materials expose you to greenwashing liability.

🎀 Handle Types: Engineering & Brand Strategy

1. Twisted Paper Handles

Construction: Multi-ply kraft paper twisted into cord (4-8mm diameter)

Load capacity: 2-4kg comfortably

Attachment method: Glued or heat-sealed to bag interior

Cost: $0.05-$0.10 per handle set (cheapest option)

Comfort: Moderate – thin handles can dig into hands with heavy loads

Aesthetic: Casual, eco-friendly, artisanal feel

Best for: Local boutiques, farmer’s market style brands, vintage clothing

Durability: Good when dry, weakens if wet (8% strength loss per TAPPI moisture tests)

2. Flat Tape Handles (PP/Ribbon)

Construction: Polypropylene ribbon (10-25mm width)

Load capacity: 4-8kg

Attachment method: Glued to reinforced patches or sewn through bag

Cost: $0.12-$0.20 per handle set

Comfort: Excellent – wide surface distributes weight, won’t cut into hands

Aesthetic: Modern, clean, customizable (available in 50+ colors)

Best for: Contemporary fashion, cosmetics, activewear retail

Durability: Superior – waterproof, maintains strength when wet

Brand opportunity: Can print logo directly on ribbon handles

Explore our custom handle paper bag options

3. Rope Handles (Cotton/Twisted)

Construction: Braided cotton or paper rope (5-8mm diameter)

Load capacity: 5-10kg (strongest option)

Attachment method: Threaded through punched holes + knotted inside bag

Cost: $0.18-$0.35 per handle set

Comfort: Premium – soft grip, ergonomic for extended carrying

Aesthetic: Luxury, tactile elegance, maritime/heritage feel

Best for: Premium fashion, department stores, high-end boutiques

Durability: Excellent – cotton rope tested to 15kg breaking strength

Environmental note: Cotton rope 100% biodegradable (composts in 6 months)

4. Die-Cut Handles

Construction: Handle cut directly from bag material (no added material)

Load capacity: 1-3kg (limited by paper strength)

Cost: $0.02-$0.05 per bag (cheapest – no handle material cost)

Comfort: Poor – sharp edges can be uncomfortable without reinforcement

Aesthetic: Minimalist, Japanese-inspired, avant-garde

Best for: Lightweight accessories, conceptual fashion brands, museum shops

Durability: Fair – requires 250+ GSM paper and reinforcement grommet

Design tip: Add soft grip coating or round edges for comfort

5. Cotton Webbing Handles

Construction: Woven cotton tape (15-25mm width)

Load capacity: 8-12kg

Attachment method: Sewn or glued with reinforced backing

Cost: $0.25-$0.45 per handle set

Comfort: Exceptional – softest, most ergonomic option

Aesthetic: Ultra-premium, reusable bag territory

Best for: Luxury flagship stores, limited edition collections

Reusability: Customers keep these bags for years (mobile brand advertising)

Environmental: Organic cotton options available (GOTS certified)

📊 Decision Matrix by Apparel Weight

Lightweight Items (Under 1kg): Ties, Socks, Underwear

Twisted paper handles or die-cut = adequate + cost-effective

Bag GSM: 120-157 GSM sufficient

Total cost: $0.30-$0.45 per bag

Medium Weight (1-3kg): Shirts, Dresses, Light Trousers

Flat tape handles or twisted paper = balanced performance

Bag GSM: 157-200 GSM recommended

Total cost: $0.50-$0.70 per bag

Heavy Items (3-6kg): Coats, Jeans, Shoes, Multiple Items

Rope handles or cotton webbing = necessary for durability

Bag GSM: 200-250 GSM minimum

Total cost: $0.80-$1.20 per bag

Reinforcement: Double-layer patches at handle attachment points

🎯 Brand Positioning Strategy

Budget/Fast Fashion ($20-50 retail):

Twisted paper handles + 157 GSM kraft bag

Simple 1-color logo print

Cost: $0.35-$0.45 per bag

Contemporary ($50-150 retail):

Flat tape handles (color-matched to brand) + 200 GSM matte bag

Full-color printing

Cost: $0.65-$0.85 per bag

Premium ($150-500 retail):

Rope handles + 250 GSM glossy lamination

Foil stamping or embossing

Cost: $1.20-$1.80 per bag

Luxury ($500+ retail):

Cotton webbing + 300 GSM + rigid cardboard base

Multi-process finishing (emboss + UV + hand-tied ribbon)

Cost: $2.50-$4.50 per bag

Reuse rate: 85%+ (per WRAP study)

🔬 Load Testing Standards

According to ASTM D4169 packaging performance standards:

Static load test: Bag filled to 120% rated capacity, hung for 30 minutes – handles should not tear or detach

Swing test: Loaded bag swung horizontally 50 times – simulates customer walking

Drop test: Loaded bag dropped from 0.5m height onto concrete – should not burst

Moisture test: Handles exposed to 80% humidity for 24 hours, strength loss should not exceed 15%

Pro Tip: Request handle pull-test reports from suppliers. Reputable manufacturers test to 3x rated load capacity. For a 5kg capacity bag, handles should withstand 15kg before failure.

💡 Cost Optimization Without Compromising Quality

Hybrid Strategy: Use rope handles only on large sizes, flat tape on medium, twisted paper on small

Small (20x10x25cm): Twisted paper handles

Medium (30x12x35cm): Flat tape handles

Large (40x15x45cm): Rope handles

Average cost savings: 22% vs. using rope handles on all sizes

📏 Garment Measurement Protocol

Step-by-Step Sizing Process:

1. Fold Garment to Retail Standard

Shirts/Blouses: Fold sleeves back, fold in half vertically, fold horizontally into thirds

Trousers/Jeans: Fold in half lengthwise, fold in half or thirds depending on length

Dresses: Fold sleeves in, fold vertically, then accordion-fold horizontally

Coats/Jackets: Fold sleeves back, fold vertically in half

Important: Use actual retail folding method, not tighter compression (customers need to refold items)

2. Measure Folded Dimensions

Length: Longest side of folded garment

Width: Shortest side

Height/Thickness: Measure at thickest point (usually collar or seams)

Tool: Use tailors measuring tape for fabric items (rigid ruler for structured items)

3. Add Clearance Allowances

Thin fabrics (silk, cotton shirts): +10-15mm per dimension

Medium fabrics (denim, cotton sweaters): +15-20mm per dimension

Thick fabrics (wool coats, puffer jackets): +20-30mm per dimension

Tissue paper wrapping: Add 5-8mm extra per layer used

Garment bag inside box: Add 3-5mm for poly bag thickness

4. Account for Box Wall Thickness

Chipboard boxes: Wall thickness typically 2-3mm

Internal dimensions = External dimensions – (2 × wall thickness)

Example: 30cm external width = ~29.4cm internal usable width

📦 Standard Apparel Box Sizes (Industry Reference)

Tie Box (Standard):

Dimensions: 37 × 7 × 3.5cm (internal)

Fits: Standard neckties folded once

GSM recommendation: 600-1000 (lightweight structure adequate)

Shirt Box (Men’s/Women’s):

Dimensions: 38 × 28 × 5cm (internal)

Fits: Dress shirts, blouses folded with tissue

GSM recommendation: 1200-1500

Most popular size in our fashion gift box collection

Sweater/Light Coat Box:

Dimensions: 40 × 30 × 8cm (internal)

Fits: Knit sweaters, cardigans, light jackets

GSM recommendation: 1500-1800

Coat/Heavy Garment Box:

Dimensions: 50 × 38 × 10cm (internal)

Fits: Winter coats, trench coats, robes

GSM recommendation: 1800-2000

Note: Consider foldable magnetic boxes for shipping efficiency

Shoe Box (Adult):

Standard: 33 × 20 × 12cm (fits most adult shoes)

Athletic: 35 × 22 × 13cm (roomier for chunky sneakers)

Boot box: 40 × 30 × 15cm (tall boots, thigh-highs)

Material: Recommend corrugated cardboard or 1800+ GSM chipboard

Lingerie/Underwear Box:

Dimensions: 25 × 20 × 5cm (internal)

Fits: Bra sets, sleepwear folded

GSM recommendation: 1000-1200

🧮 Sizing Calculator Formula

Internal Box Dimension = Garment Dimension + Clearance + Tissue/Insert Allowance

Example: Men’s Dress Shirt

Folded garment: 36cm (L) × 26cm (W) × 4cm (H)

Fabric type: Medium weight cotton

Clearance: +15mm per side

Tissue paper: 2 layers = +6mm

Calculation: Length: 36cm + 1.5cm + 0.6cm = 38.1cm → round to 38cm

Width: 26cm + 1.5cm + 0.6cm = 28.1cm → round to 28cm

Height: 4cm + 1.5cm + 0.6cm = 6.1cm → round to 6cm

Optimal box: 38 × 28 × 6cm internal

⚠️ Common Sizing Mistakes

Mistake 1: Measuring Compressed Garment

Problem: Pressing garment flat gives false readings

Reality: Fabric naturally lofts; compressed measurement = too-tight box

Fix: Measure garment in natural resting state after folding

Mistake 2: Ignoring Seam Bulk

Problem: Collar bands, cuffs, pockets add thickness not visible in flat measurement

Reality: Box lid won’t close or crushes garment

Fix: Always measure at thickest point (usually collar area)

Mistake 3: Exact-Fit Mentality

Problem: “My shirt is 36cm, so 36cm box is perfect”

Reality: Zero clearance = insertion friction, fabric snags, damaged packaging

Fix: Minimum 10mm clearance per side (20mm total per dimension)

Per ISTA guidelines, 3-5% clearance is standard

Mistake 4: Over-Sizing for “Premium Feel”

Problem: “Bigger box = more luxury”

Reality: 30%+ empty space signals cheap filler, not quality

Consumer perception study: Garment should occupy 60-75% of box volume

Fix: Size appropriately, use quality tissue/ribbon for premium feel instead

🌡️ Seasonal Sizing Considerations

Summer/Spring Lightweight Apparel:

Thinner fabrics compress more

Can use slightly smaller boxes than measurements suggest

Example: T-shirt folded 4cm thick → 5cm box adequate (vs. 6cm for winter shirt)

Fall/Winter Heavy Apparel:

Wool, fleece, down don’t compress well

Add extra 20-30% height allowance

Example: Wool sweater 8cm thick → need 10-11cm box (not 9cm)

Consider vacuum-sealed poly bags inside box for bulky items

📦 Multi-Item Packaging Solutions

Coordinated Sets (Shirt + Tie):

Use shirt box dimensions, add shallow tray on top for tie

Total height: Shirt box 5cm + tie tray 3cm = 8cm combined box

Gift Sets (Multiple Small Items):

Calculate total volume needed

Add dividers (2-4mm thick each) between items

Example: 3 pairs of socks = base 25 × 20cm, height 5cm + dividers

Layered Packaging:

Bottom layer: Heavier item (jeans)

Top layer: Lighter item (shirt)

Separator: Tissue paper or thin cardboard (2mm)

Box height = Sum of item heights + separator + clearances

💡 Cost-Saving Sizing Strategy

Standardize to 3-5 Box Sizes:

Small: 30 × 25 × 5cm (accessories, lightweight items)

Medium: 38 × 28 × 6cm (shirts, blouses, most apparel)

Large: 45 × 35 × 8cm (sweaters, light coats)

XL: 50 × 40 × 10cm (winter coats, multiple items)

Benefits:

Bulk pricing on repeated sizes (20-30% discount at 10,000+ units)

Simplified inventory management

Faster staff training (fewer size options to remember)

Reduced tooling costs for custom printing

Volume Optimization:

Right-sizing reduces material waste by 15-25% and shipping dimensional weight charges. A study by Packaging Digest found that optimized apparel packaging cuts logistics costs by $0.40-$0.80 per box.

📦 Rigid vs Foldable: Structural Comparison

Rigid/Set-Up Boxes (Pre-Assembled):

Construction: Chipboard base + lid, arrive fully assembled

Advantages: No assembly time required

Luxury unboxing experience

Superior crush resistance for retail display

Disadvantages: Ship fully assembled = occupies full volume

Shoe box example: 33 × 20 × 12cm assembled

Cannot be compressed or nested

Warehouse storage inefficiency

Foldable/Collapsible Boxes:

Construction: Die-cut cardboard with scored fold lines, ships flat

Advantages: Flat-packed thickness: 2-4cm regardless of assembled height

Stackable: 100+ boxes in space of 10 rigid boxes

Assembly time: 10-20 seconds per box (trained staff)

Disadvantages: Requires labor for assembly (mitigated by simple design)

Slightly less crush-resistant than rigid (acceptable for shipping)

Explore our complete foldable box collection

💰 Shipping Cost Reality Check

Real-World Scenario: 5,000 Shoe Boxes from China to US

Rigid Pre-Assembled Boxes:

Box dimensions: 33 × 20 × 12cm (assembled)

Packing density: 15-20 boxes per master carton

Total master cartons needed: 250 cartons

Volumetric weight: ~18 CBM

Ocean freight: Requires 2 × 20ft containers

Freight cost: $3,500 × 2 = $7,000

Per-box shipping: $1.40

Foldable Boxes (Same Final Dimensions):

Flat-packed thickness: 3cm

Packing density: 100-120 boxes per master carton

Total master cartons: 45 cartons

Volumetric weight: ~3.2 CBM

Ocean freight: LCL (shared container space)

Freight cost: $1,400

Per-box shipping: $0.28

✅ Savings: $5,600 (80% reduction)

🏢 Warehouse Storage Analysis

Rigid Box Storage (10,000 units inventory):

Space required: 500 master cartons × 0.8 CBM = 400 CBM

Warehouse rent: $12/CBM/month × 400 = $4,800/month

Annual storage cost: $57,600

Handling: Requires forklift due to bulk

Foldable Box Storage (10,000 units inventory):

Space required: 90 master cartons × 0.6 CBM = 54 CBM

Warehouse rent: $12/CBM/month × 54 = $648/month

Annual storage cost: $7,776

Handling: Hand-stackable, flexible placement

✅ Savings: $49,824/year (86.5% reduction)

⚙️ Assembly Labor Cost Analysis

Labor Economics:

Assembly time per box: 12-18 seconds (shoe boxes)

Worker productivity: 200-250 boxes/hour

Labor cost at $15/hour: $0.06-$0.08 per box

Break-Even Calculation (5,000 boxes):

Assembly labor total: 5,000 × $0.07 = $350

Shipping savings: $5,600

Storage savings (6 months): $4,800 × 6 = $28,800

Total savings: $5,600 + $28,800 – $350 = $34,050

ROI: 9,729% on assembly labor investment

🔧 Assembly Process Optimization

Setup Efficiency Tips:

Folding jig: Simple cardboard template reduces training from 2 hours to 20 minutes

Station layout: Flat boxes on left, assembly space center, completed boxes right

Batch processing: Assemble 50-100 boxes at once (rhythm improves speed 30%)

Quality check: Box should “pop” into shape with crisp folds – indicates good die-cutting

Training Curve:

Day 1: 120-150 boxes/hour (learning)

Day 3: 200-220 boxes/hour (competent)

Week 2: 250-280 boxes/hour (proficient)

📊 When Rigid Boxes Make Sense

Rigid boxes preferred if:

Ultra-low volume: <500 boxes/year (assembly labor exceeds savings)

Retail floor displays: Boxes stacked for visual merchandising (rigidity matters)

No assembly capacity: Small operations without packing staff

Immediate fulfillment: Same-day ship requirements (no time to assemble)

Foldable boxes optimal for:

E-commerce operations: High volume, centralized packing

Multi-location distribution: Ship flat to stores, assemble on-site

Seasonal businesses: Store flat during off-season, assemble when needed

Growing brands: Uncertain demand – stock flat boxes without tying up capital in warehouse space

🌍 Environmental Impact

According to EPA Sustainable Materials Management data:

Transportation emissions: Foldable boxes reduce shipping emissions by 75-80% (fewer trucks/containers needed)

Material efficiency: Same final box, but flat-packing enables lighter master cartons (15% less corrugated material)

Carbon footprint: 5,000 foldable boxes = 2.3 tons CO2 saved vs. rigid boxes (freight + storage combined)

🎯 Hybrid Strategy for Luxury Brands

Premium Unboxing Without Sacrificing Efficiency:

Use foldable magnetic closure boxes – ship flat, assemble to rigid-box quality

Magnetic flap design adds luxury feel

Still saves 70-75% on logistics vs. traditional rigid

Cost: $0.20-$0.35 more than basic foldable, but $0.80-$1.20 cheaper to ship than rigid

Net savings: $0.60-$0.85 per box while maintaining premium positioning

Case Study: Premium sneaker brand switched to foldable magnetic boxes:

Volume: 80,000 boxes/year

Previous rigid box cost: $2.50/box + $1.40 shipping = $3.90 total

New foldable magnetic: $1.80/box + $0.30 shipping + $0.08 assembly = $2.18 total

Annual savings: $137,600

Customer feedback: 94% couldn’t distinguish from rigid boxes in blind test

🔬 Material Science: Recycled vs Virgin Fiber

Fiber Structure Analysis:

Virgin Fiber Chipboard:

Fiber length: 2-4mm (longer = stronger)

Fiber integrity: 100% undamaged cellulose chains

Bonding strength: Maximum inter-fiber bonding

Density uniformity: Highly consistent (±3% variance)

Color: Bright white or consistent grey

100% Post-Consumer Recycled (PCR) Fiber:

Fiber length: 1-3mm (shortened during recycling process)

Fiber integrity: 10-15% fiber damage from mechanical processing

Bonding strength: 8-12% weaker than virgin (USDA Forest Products Lab data)

Density uniformity: Moderate (±6-8% variance)

Color: Natural grey-brown, may have slight color variation

💪 Performance Testing Results

Burst Strength Comparison (per ISO 2758):

1500 GSM Virgin Fiber:

Burst strength: 340 kPa

Edge crush test (ECT): 32 kN/m

Suitable for: All apparel packaging applications

1500 GSM 100% PCR:

Burst strength: 295 kPa (-13%)

Edge crush test (ECT): 28 kN/m (-12.5%)

Suitable for: Most apparel (see mitigation strategies below)

Real-World Impact Translation:

For shirt boxes: No performance difference – both handle typical loads (500g-1.5kg)

For coat boxes: Minimal impact – 13% strength reduction still exceeds requirements

For shoe boxes: May require GSM upgrade (1500 → 1800 GSM) to match virgin 1500 GSM performance

🛡️ Mitigation Strategies for 100% PCR

1. Increase GSM by 15-20%:

Replace virgin 1200 GSM → PCR 1500 GSM

Replace virgin 1500 GSM → PCR 1800 GSM

Cost impact: +$0.08-$0.15 per box

Result: Matches or exceeds virgin fiber performance

2. Add Surface Lamination:

Matte or gloss lamination increases structural rigidity by 18-25%

Acts as reinforcing layer, compensates for slightly weaker fiber

Cost: +$0.12-$0.18 per box (also improves aesthetics)

Dual benefit: Performance + premium appearance

3. Reinforce Stress Points:

Double-layer corners (where lid meets base)

Reinforced lid edges for flip-top boxes

Cost: +$0.05-$0.10 per box

Targeted solution for heavy apparel (coats, shoes)

📊 Long-Term Durability Studies

According to TAPPI accelerated aging tests:

Shelf-Life Performance (Controlled Environment: 20°C, 50% RH):

Virgin fiber boxes: 5+ years before yellowing or brittleness

100% PCR boxes: 3-4 years before minor discoloration (strength maintained)

Practical impact: Zero difference for retail apparel (typical box life: 6-18 months)

Moisture Resistance:

Virgin fiber: Absorbs 8-10% moisture at 70% humidity

100% PCR: Absorbs 10-12% moisture (slightly more hygroscopic)

Solution: Moisture-resistant coating adds $0.06-$0.10/box, equalizes performance

💰 Cost-Performance Trade-Off Analysis

Scenario: 10,000 Shirt Boxes Annually

Option A: Virgin Fiber 1200 GSM

Unit cost: $0.95/box

Total: $9,500

Performance: Excellent

Environmental story: Limited

Option B: 100% PCR 1200 GSM (Direct Substitute)

Unit cost: $0.85/box (-11%)

Total: $8,500

Performance: Good (adequate for shirts, 8-12% weaker)

Savings: $1,000/year

Environmental story: Strong

Option C: 100% PCR 1500 GSM + Matte Lamination

Unit cost: $1.08/box (+14% vs virgin)

Total: $10,800

Performance: Superior to virgin 1200 GSM

Additional cost: $1,300/year

Benefit: Premium aesthetics + environmental credentials + stronger box

Value proposition: Justify 15-20% product price increase with sustainability story

🎯 Application-Specific Recommendations

Lightweight Accessories (Ties, Socks, Scarves):

100% PCR 600-1000 GSM = Perfect substitute

No performance compromise

Cost savings: 10-15%

Verdict: Always choose PCR

Standard Garments (Shirts, Blouses, Dresses):

100% PCR 1200-1500 GSM = Excellent substitute

Minimal performance difference

Cost savings: 8-12%

Verdict: PCR recommended for most brands

Heavy Apparel (Coats, Jeans, Leather):

100% PCR 1800-2000 GSM = Adequate with lamination

Consider virgin/PCR blend (70/30) for optimal balance

Cost: Comparable to virgin

Verdict: PCR viable with proper GSM selection

Footwear:

Corrugated cardboard (inherently recycled content) = Industry standard

100% PCR chipboard: Increase to 2000 GSM or use corrugated

Cost: PCR chipboard +$0.10-$0.15 vs virgin, corrugated often cheaper

Verdict: Corrugated preferred for shoes (recycled content + lower cost)

See our eco-friendly shoe box options

♻️ Environmental Impact Quantification

According to EPA WARM model:

10,000 Apparel Boxes (1500 GSM, 35 × 28 × 6cm average):

Virgin Fiber Production:

Trees required: ~4.2 tons of wood pulp

Water consumption: 280,000 liters

Energy: 45,000 kWh

CO2 emissions: 8.5 tons

100% PCR Production:

Trees required: 0 (waste paper diverted from landfill)

Water consumption: 140,000 liters (-50%)

Energy: 27,000 kWh (-40%)

CO2 emissions: 3.2 tons (-62%)

Environmental savings: 5.3 tons CO2 equivalent

Marketing Value Translation:

For consumer-facing brands: “Our packaging prevents 5.3 tons of CO2 emissions annually – equivalent to taking 1.2 cars off the road”

For ESG reporting: Direct Scope 3 emissions reduction quantified

For retail partnerships: Meets sustainability requirements for major chains

🔍 How to Verify Recycled Content Claims

Request from Supplier:

FSC Recycled Certification: Chain-of-custody certificate proving 100% PCR content

Third-party testing: TAPPI T 401 fiber analysis report (identifies virgin vs recycled)

Mill certifications: ISO 14001 environmental management + recycled content attestation

Visual inspection: 100% PCR has natural grey-brown color (pure white = likely virgin or bleached)

Red Flags:

Supplier claims “100% recycled” but boxes are bright white without bleaching upcharge

No FSC certificate number visible or verifiable

Price identical to virgin fiber (true PCR usually 5-15% cheaper)

Verify FSC Claims: Enter certificate code at FSC database to confirm legitimacy

💡 Best Practice Recommendation

For 95% of Apparel Applications:

Use 100% PCR material at same or +1 GSM tier vs virgin

Add matte lamination for premium lines (aesthetics + strength boost)

Total cost: -5% to +10% vs virgin, depending on finish

Performance: Equal or better with proper specification

Environmental credentials: Significant and quantifiable

Consumer perception: Nielsen research shows 73% willing to pay more for sustainable packaging

Conclusion: 100% recycled materials do NOT compromise performance when properly specified. Minor strength differences (8-12%) are easily compensated through GSM adjustment or lamination, often at lower total cost than virgin alternatives.

Explore sustainable options with our custom eco-packaging service

🌍 Regulatory Landscape Overview

Why FSC Matters for B2B Procurement:

Not just “eco-friendly marketing” – increasingly a legal and commercial requirement

Major retailers mandate FSC for supplier onboarding

Regulatory compliance in key markets (EU, US, UK)

Risk mitigation against greenwashing accusations

🇪🇺 European Union Requirements

EU Deforestation Regulation (EUDR) – Effective December 2025:

Scope: Applies to paper, cardboard, and packaging materials

Requirement: Importers must prove products don’t contribute to deforestation

Compliance pathway: FSC certification provides streamlined due diligence

Non-compliance penalty: Products blocked at customs + fines up to 4% of EU turnover

Impact on apparel brands: Cannot import packaging from non-compliant suppliers

Source: European Commission EUDR Guidelines

Extended Producer Responsibility (EPR) Directives:

Germany (VerpackG): Packaging must be registered, FSC-certified materials reduce EPR fees

France: AGEC law requires 100% recyclable packaging by 2025 (FSC Recycled qualifies)

Netherlands: Packaging tax structure favors certified sustainable materials (15-20% lower fees)

Financial impact: FSC certification saves €0.02-€0.05 per box in EPR fees across EU

Major EU Retailer Mandates:

H&M Group: 100% FSC or equivalent required for all packaging suppliers (since 2023)

Inditex (Zara): FSC certification mandatory for Tier 1 packaging suppliers

LVMH: FSC-certified packaging preferred, non-certified requires additional audits

Source: Corporate sustainability reports + supplier portals

🇺🇸 United States Market Dynamics

Lacey Act (Federal Law):

Prohibits: Trade in illegally sourced wood products, including paper/cardboard

Burden of proof: Importers must demonstrate legal sourcing

FSC benefit: Provides legal safe harbor – certification = compliant sourcing proof

Penalties: Criminal liability + forfeiture of goods for non-compliance

Reference: USDA Lacey Act Guidelines

State-Level Regulations:

California:

SB 270 (Reusable Bag Standards): FSC certification preferred for paper shopping bags

Proposition 65: Requires disclosure of chemicals – FSC materials have cleaner supply chains

CalRecycle targets: 75% recycling rate by 2025 – FSC Recycled content contributes

New York:

NY Environmental Conservation Law: Packaging reduction mandates favor certified materials

NYC retail requirements: Many stores prefer FSC suppliers for municipal contracts

🏢 Major US Retailer Requirements

Walmart:

Project Gigaton goal: Supplier packaging must be sustainably sourced

FSC certification earns points in supplier scorecard

Preferred supplier status = better shelf placement + order priority

Target:

Sustainable Product Standard: FSC certification required for private label packaging

Third-party brands strongly encouraged (90% compliance target by 2025)

Nordstrom:

Packaging guidelines mandate FSC certification for luxury brands

Non-certified suppliers undergo additional sustainability audits (delays onboarding 4-6 weeks)

Amazon:

Climate Pledge Friendly program: FSC-certified packaging earns badge

Products with badge see 18-25% higher conversion rates (Amazon internal data)

🇬🇧 UK Post-Brexit Landscape

UK Timber Regulation (UKTR):

Mirrors EU requirements, independent enforcement

FSC certification simplifies compliance documentation

Trading Standards enforcement: £5,000-£1,000,000 fines for non-compliance

Plastic Packaging Tax (PPT):

£200/tonne tax on packaging with <30% recycled content

FSC Recycled paper alternatives avoid plastic bag taxes

Incentivizes paper bags over plastic (apparel sector shift visible)

📊 B2B Procurement Decision Framework

Risk Assessment Matrix:

Scenario 1: Target Market = EU Only

FSC Certification: MANDATORY (EUDR compliance)

Recommended level: FSC Mix minimum, FSC Recycled preferred

Cost impact: +6-10% vs non-certified

Risk of non-compliance: Customs rejection, legal liability, brand damage

Decision: Non-negotiable requirement

Scenario 2: Target Market = US Major Retailers

FSC Certification: HIGHLY RECOMMENDED (retailer mandates)

Recommended level: FSC Mix sufficient for most

Cost impact: +6-10%

Risk of non-compliance: Supplier disqualification, lost contracts ($100k-$500k+ value)

Decision: Essential for retail partnerships

Scenario 3: Target Market = Direct-to-Consumer (DTC) Brands

FSC Certification: MARKETING ADVANTAGE

Recommended level: FSC Recycled for strongest story

Cost impact: -5% to +5% (PCR recycled often cheaper)

Consumer premium: 12-18% higher perceived value (Nielsen study)

Decision: ROI-positive investment

Scenario 4: Target Market = Budget/Fast Fashion

FSC Certification: OPTIONAL BUT EMERGING

Recommended level: FSC Mix (lowest cost tier)

Cost impact: +6-8%

Competitive pressure: Peers adopting = market expectation shifting

Decision: Adopt now to future-proof supply chain

💰 Total Cost of Ownership Analysis

Case Study: Mid-Market Fashion Brand – 100,000 boxes/year

Non-Certified Approach:

Box cost: $0.95 × 100,000 = $95,000

Risk costs: EU market access: Blocked (potential revenue loss: $500k-$2M)

US retailer rejection: 30-40% of partnerships unavailable

Compliance audits: $15,000-$25,000 annually

True cost: $95,000 + massive opportunity cost

FSC Mix Certified Approach:

Box cost: $1.03 × 100,000 = $103,000 (+$8,000)

Benefits: Full EU market access (revenue potential: $500k-$2M)

US retailer qualification: 100% of partnerships available

Reduced EPR fees (EU): -$2,000-$5,000/year

Marketing differentiation: Visible FSC logo

Simplified compliance: No additional audits needed

Net ROI: $8,000 investment unlocks $500k+ market access

🎯 Procurement Best Practices

1. Verify Certification Legitimacy:

Request FSC certificate number from supplier

Verify at FSC database (enter cert code)

Check certificate validity dates (must be current)

Confirm supplier’s chain-of-custody certification (not just materials)

2. Specify Certification in Contracts:

Include FSC requirement in RFQ/Purchase Orders

Request FSC logo usage rights for your packaging

Specify certificate documentation delivery timeline

Include non-compliance penalties (material breach clause)

3. Tier Your Certification Strategy:

EU-destined products: FSC mandatory

US major retailer products: FSC strongly recommended

Domestic/local markets: FSC optional but beneficial

Luxury lines: FSC 100% for premium positioning

Volume lines: FSC Mix for cost optimization

4. Communicate Certification to Stakeholders:

Print FSC logo on packaging (requires license agreement)

Include in ESG reports: Quantify environmental impact (see Q9)

Retail presentations: Highlight compliance as competitive advantage

Consumer-facing: “FSC-certified packaging” on product pages/tags

⚠️ Common Pitfalls to Avoid

Mistake 1: “FSC-Equivalent” Claims

Problem: Suppliers claim “sustainable sourcing” without FSC certification

Reality: Only FSC/PEFC certifications recognized by retailers and regulators

Risk: Greenwashing liability, regulatory non-compliance

Fix: Insist on actual FSC certificate, not vague sustainability claims

Mistake 2: Mixing Certified and Non-Certified Batches

Problem: Ordering some FSC, some non-FSC to save costs

Reality: Requires segregated inventory, risks cross-contamination claims

Fix: Standardize on FSC for all SKUs within same product line

Mistake 3: Ignoring Chain-of-Custody

Problem: Materials are FSC but supplier lacks chain-of-custody certification

Reality: Cannot legally claim FSC packaging without certified handler

Fix: Verify supplier’s FSC COC certificate, not just material source

🔮 Future-Proofing Your Supply Chain

Emerging Trends (2025-2027):

Digital Product Passports (EU): QR codes linking to sustainability documentation – FSC data must be digitally traceable

Scope 3 Emissions Reporting: Brands required to report supply chain emissions – FSC materials reduce calculated footprint

Retailer Sustainability Tiers: Premium shelf placement reserved for FSC-certified suppliers

Consumer Verification Apps: Shoppers scanning packaging to verify sustainability claims – FSC logos instantly recognizable

Strategic Recommendation:

Transition 100% of apparel packaging to FSC certification within 12-18 months. The cost premium (6-10%) is offset by market access, regulatory compliance, consumer preference, and future-proofing against tightening regulations. Non-certified packaging increasingly represents a commercial liability rather than a cost savings.

Partner with certified suppliers through our custom packaging service with full FSC chain-of-custody documentation.