Wholesale Foldable Gift Boxes In Stock are available here for immediate dispatch. UGI is your factory-direct supplier for these collapsible magnetic boxes, designed to save you up to 80% on shipping and storage costs.

Wholesale Foldable Gift Boxes In Stock – Ready to Ship & No MOQ!

In this catalog, all foldable boxes are in stock, with a daily production capacity of over 60,000 boxes. We welcome your orders with no minimum order quantity, and customization is available based on customer requirements!

Magnetic Double Door Box

We offer Magnetic Double Door Gift Boxes with Ribbon, designed with a foldable cardboard structure for easy storage and shipping. Perfect for presents, events, and retail packaging. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou, China-based factory.

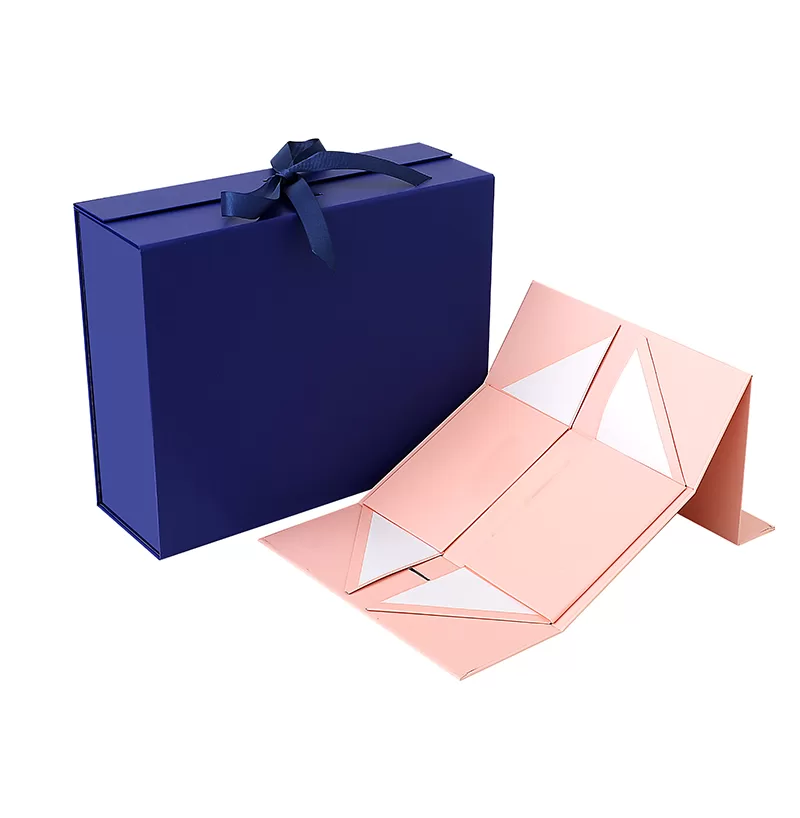

Luxury Foldable Magnetic Box

We offer Luxury Foldable Magnetic Ribbon Gift Boxes, made from sturdy cardboard with a matte or embossed finish. Perfect for packaging gifts, and more. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou, China-based factory.

Magnetic Gift Box with Lids

We offer Magnetic Gift Boxes with Lids, featuring a foldable box structure and sturdy design. Perfect for packaging luxury items, gifts, or special occasions. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou, China-based factory.

Foldable Wine Magnetic Box

We offer a range of foldable gift boxes designed to hold 1 or 2 bottles of wine, made with high-quality materials and elegant designs. Perfect for retail, events, or luxury gifting. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou-based factory.

Foldable Magnetic Gift Box

We provide Foldable Magnetic Gift Boxes with Handle, crafted from high-quality materials and designed for both style and convenience. Perfect for retail, corporate gifts, and special events. Benefit from flexible MOQs, fast delivery, and competitive pricing, all directly from our Guangzhou factory.

Velvet Foldable Keepsake Box

We offer Velvet Foldable Keepsake Boxes, crafted with soft, luxurious velvet and designed for storing cherished items. Ideal for gifts, jewelry, or special memories. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou, China-based factory.

Luxury Magnetic Handbag Box

We offer Foldable Gift Boxes with Handle like a handbag, made from high-quality materials with a stylish design. Perfect for retail, gifting, and events. Enjoy flexible MOQs, fast shipping, and competitive prices directly from our Guangzhou-based factory to meet your needs.

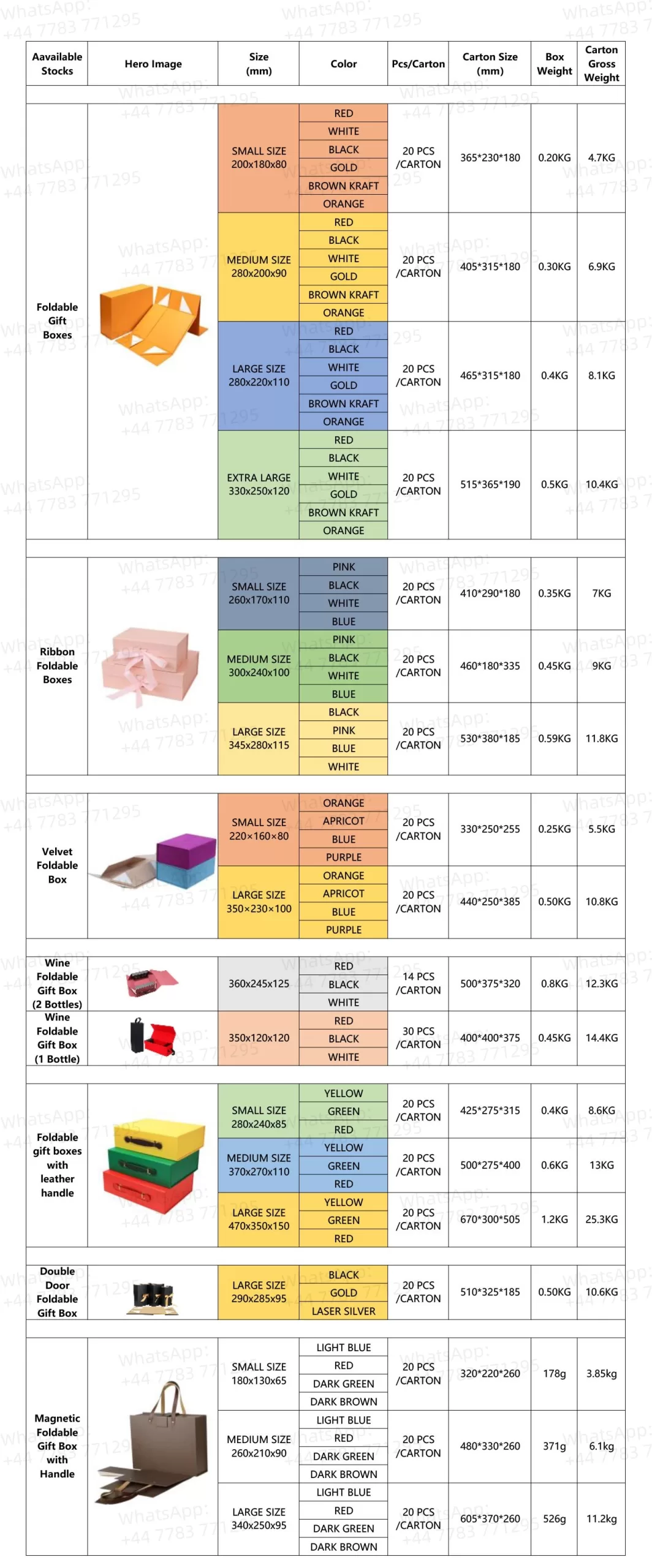

Packing Info:

The carton dimensions after packing the foldable boxes are as follows.

Product Catalog in Video Format

We present our foldable gift boxes in stock and ready to ship through a video product catalog, showcasing each style’s structure, materials, and finishing details. This dynamic format lets you view the quality, durability, and folding mechanism in action, helping you select the perfect packaging solution for retail, events, or luxury gifting with confidence.

📢 Get in Touch Today!

We specialize in supplying Wholesale Foldable Gift Boxes In Stock and fully customized packaging solutions for global businesses. Let’s create something extraordinary together. Contact us for samples or partnership opportunities!

As a professional packaging factory in Guangzhou, China, we offer fully customized gift boxes & bags tailored to your branding needs. We can create the perfect solution to elevate your packaging. Let us know your product type, and we’ll recommend the best options!

📞 Contact Us for a Free Quote

Email: [[email protected]]

Website: [ukugi.com/show]

WhatsApp: [ +44 7783 771295]

Call to speak with one of our experts to get more details about our custom packaging offerings, and a dieline template for your packaging:

Let’s talk

Our WhatsApp is online 24/7.

If you have any questions, you can contact our customer service at any time.

FAQ – Common Questions About Our Products

📦 Primary Industries

Luxury Retail & E-commerce

High-end fashion accessories, watches, and jewelry brands

Focus: creating premium unboxing experiences for luxury perception

Beauty & Cosmetics

Used for skincare sets, perfume collections, and limited edition launches

Brand presentation directly influences purchasing decisions

Wine & Spirits

Adopted by boutique wineries, craft distilleries, and corporate gifting programs

Available in 1–2 bottle configurations

Electronics & Tech

Ideal for premium headphones, smart devices, and collector’s editions

Protective structure enhances perceived value and product safety

Corporate Gifting

Used in employee recognition programs and client appreciation kits

Common order volumes: 1,000–50,000+ units annually

Event & Wedding Industry

Perfect for welcome boxes, bridesmaid gifts, and luxury event favors

Designed for easy storage and efficient setup before events

📊 Business Scenario Analysis

Scenario A: Seasonal Inventory Management

Retailers preparing for Q4 holidays can stock our Wholesale Foldable Gift Boxes In Stock that consume 80% less warehouse space. They can assemble boxes on demand as order volumes fluctuate, minimizing storage costs and optimizing flexibility.

Scenario B: Multi-Location Distribution

Brands with 20+ retail outlets benefit from massive freight savings. A 40ft container can fit 60,000 foldable boxes versus only 12,000 rigid boxes — delivering up to 5× distribution efficiency and lower logistics costs.

Scenario C: Pop-Up & Trade Show Operations

Event marketers transporting packaging to temporary venues enjoy easy handling. Flat-packed units are lightweight and portable, allowing one person to carry them, unlike pre-assembled boxes that require freight logistics.

Available Finishing Options

1. Matt Lamination

Application: Luxury skincare, high-end electronics

Tactile Benefit: Soft-touch feel signals premium quality, reduces fingerprints

Cost Impact: +8-12% vs. uncoated

2. Glossy Lamination

Application: Vibrant cosmetics, youth-oriented brands

Visual Impact: Color saturation increases 30-40%, creates high-shine effect

Durability: Scratch-resistant surface for retail handling

3. Hot Stamping (Gold/Silver Foil)

Application: Luxury goods, award presentations, wedding packaging

Technical Note: Works on both matte and glossy bases, logo sizes 10mm minimum recommended

Premium Positioning: Adds $0.30-$0.80 per box depending on foil coverage area

4. Embossing/Debossing

Application: Corporate branding, leather goods packaging

Tactile Differentiation: Creates 0.3-0.8mm depth, brand logos become 3D touchpoints

Best Practice: Combine with foil stamping for maximum impact

5. Spot UV Coating

Application: Creating contrast between matte base and glossy logo areas

Design Strategy: Highlights specific brand elements, creates modern aesthetic

Technical Advantage: No additional structural cost, purely visual enhancement

6. Varnishing

Application: Budget-conscious brands needing basic protection

Function: Seals print, provides minimal gloss, most economical finish option

Finishing Combination Example

Matte lamination base + debossed logo + gold foil fill = luxury tier positioning (ideal for beauty and jewelry sectors)

Available Structural Designs

1. Magnetic Double-Door Box (Model: DFB73066)

Mechanism: Two front panels open outward, magnetic closure at center seam

Folding Method: Bottom-fold flat pack, 4 magnetic contact points

Assembly Time: 8-12 seconds per unit (trained staff)

Ideal For: Luxury reveals, products requiring dramatic unboxing

2. Flip-Top Magnetic Box with Ribbon

Mechanism: Single lid lifts from front, ribbon handle integrated

Folding Method: Collapsible lid + body, magnets embedded in lid flap

Portability Feature: Ribbon handle supports 3-5kg weight capacity

Use Case: Portable gifts, handbag-style packaging

3. Handbag-Style Foldable Box (Model: FBH73058)

Mechanism: Handle integrated into lid structure, magnetic side closures

Folding Innovation: Handle collapses flat within lid fold

Differentiation: Combines gift box + shopping bag functionality

Market Position: Premium retail takeaway packaging

4. Wine Bottle Configurations (1-2 bottle capacity)

Structural Engineering: Reinforced base board (2000 GSM) for weight distribution

Folding Complexity: Side panels with pre-scored fold lines, bottle dividers fold flat

Assembly: 15-20 seconds due to additional stability features

5. Velvet-Lined Keepsake Box (Model: FWB73018)

Material Innovation: Outer rigid board + interior velvet flocking

Folding Challenge: Fabric liner pre-attached, fold pattern minimizes crease stress

Premium Application: Jewelry, watch boxes, heirloom items

Folding Mechanism Technical Details

All boxes use 180° reverse-fold engineering where:

Fold lines are precision-die-cut with 0.2mm tolerance

Magnetic strips (8-12mm width) are embedded during production, not post-applied

Corner stress points reinforced with double-layer board lamination

Flat-packed dimensions typically 2.5-3.5cm thickness regardless of assembled height

Standard Insert Materials

1. EVA Foam Inserts

Density Options: 25D (soft), 35D (medium), 50D (firm)

Customization: CNC-cut cavities to exact product dimensions (tolerance ±0.5mm)

Protection Level: Shock absorption for electronics, glass, fragile items

Color Range: Black, white, custom color matching available (MOQ 500+ units)

Cost: $0.80-$2.50 per insert depending on complexity

2. Rigid Paperboard Dividers

Structure: 600-1200 GSM board, same material as box body

Configuration: Fixed compartments, removable sections, adjustable slots

Surface Treatment: Matches outer box finish (matte/glossy lamination)

Application: Cosmetic sets, multi-item gift assortments, product families

Sustainability: 100% recyclable with main box structure

3. Flocked Velvet Trays

Material: Velvet fabric adhered to rigid base board

Luxury Positioning: Jewelry, watches, high-end cosmetics

Aesthetic Benefit: Conceals product shift during transport, adds retail-display quality

Color Options: Black, burgundy, navy, custom colors (MOQ 1000+)

4. Silk/Satin Bedding

Application: Wrapping individual items within box, luxury gift presentation

Material: Polyester satin, silk-blend options

Function: Creates unboxing layers, protects surfaces from scratches

Cost-Effective Alternative: Tissue paper with custom printing

5. Transparent PET/PVC Windows

Integration: Die-cut window in lid, clear film heat-sealed

Product Visibility: Allows retail shelf display without opening

Technical Consideration: Does not fold completely flat (adds 0.5-1cm to packed thickness)

Ideal For: Food packaging, visible product displays

Custom Insert Design Process

Client provides product dimensions + weight

Factory engineers cavity layout with 2-3mm clearance per side

Digital proof with 3D rendering

Physical sample insert for fit testing (3-5 days)

Production tooling (one-time fee: $100-$300 depending on complexity)

Insert Selection Guide

Electronics → EVA Foam 35D-50D (Impact protection, static reduction)

Cosmetics → Paperboard dividers + satin bedding (Cost-effective, maintains product position)

Jewelry → Flocked velvet tray (Luxury perception, scratch prevention)

Wine bottles → None or paperboard stabilizer (Bottle shape self-supports in fitted box)

Multi-SKU sets → Adjustable paperboard dividers (Flexibility for product variations)

📦 Shipping Cost Comparison – Real Example

Scenario: US-based retailer ordering 10,000 gift boxes from China

Rigid Pre-Assembled Boxes:

Box dimensions: 20cm x 15cm x 10cm (assembled)

Packing density: 20 boxes per carton

Total cartons: 500 cartons

Ocean freight: 18 pallets = 2 FULL CONTAINERS required

Freight cost: $6,000 x 2 = $12,000

Foldable Boxes (Same Specs):

Flat-packed thickness: 3cm

Packing density: 100 boxes per carton

Total cartons: 100 cartons

Ocean freight: 4 pallets = Shares container (LCL)

Freight cost: $2,200

Savings: $9,800 (81.7% reduction)

📦 Warehouse Storage Cost Analysis

Rigid boxes:

Space: 500 cartons x 0.8 cbm = 400 cbm

Monthly rate: $8-12 per cbm = $3,200-$4,800/month

Annual cost: $38,400-$57,600

Foldable boxes:

Space: 100 cartons x 0.6 cbm = 60 cbm

Monthly rate: $8-12 per cbm = $480-$720/month

Annual cost: $5,760-$8,640

Savings: $32,640-$48,960 (85% reduction)

📦 Break-Even Calculation

If assembly labor costs $0.15 per box:

Additional labor cost for 10,000 boxes = $1,500

Freight savings = $9,800

Storage savings = $32,640 (low estimate)

Assembly cost = -$1,500

Total Net Savings: $40,940 in first year

📦 When Rigid Boxes Make More Sense

Ultra-low volume (<500 units/year): Assembly labor exceeds shipping savings

Time-critical fulfillment: No staff available for assembly, direct-ship priority

Complex structural designs: Boxes requiring >30 seconds assembly time (rare)

Retail floor displays: Pre-assembled units needed for immediate shelf placement

Assembly Time Standards

Per box (trained worker):

Simple flip-top magnetic box: 8-12 seconds

Double-door magnetic box: 10-15 seconds

Handbag-style with handle: 12-18 seconds

Wine box with divider: 15-20 seconds

Labor Cost Calculation

Example: 1,000 boxes/day fulfillment center

Average assembly time: 12 seconds per box

Total labor hours: (1,000 × 12 seconds) ÷ 3,600 = 3.33 hours

Labor cost at $15/hour: $50/day

Cost per box: $0.05

For Comparison:

Shipping cost savings per box: $0.98

Storage cost savings per box: $3.26 annually

Assembly cost: $0.05

Net Savings Per Box: $4.19

Operational Integration Strategies

1. Pre-Peak Season Preparation

Assemble 30-40% of projected holiday inventory during slow months

Store assembled boxes (still saves 60% space vs. ordering rigid boxes)

Reduces peak-season labor crunch

2. Assembly Station Setup

Dedicated 2m x 1m workspace per worker

Boxes delivered flat-stacked (50-100 units per stack)

Simple folding jig reduces training time from 2 hours to 30 minutes

Productivity: Experienced worker assembles 250-300 boxes/hour

3. Quality Control Integration

Assembly coincides with product insertion = single-step QC

Workers check box structure + product placement simultaneously

No additional handling step vs. rigid boxes

Training Curve

Day 1: 100 boxes/hour (learning phase)

Day 3: 200 boxes/hour (competent)

Week 2: 250-300 boxes/hour (proficient)

Automation Potential

For volumes exceeding 50,000 boxes/month:

Semi-automated folding machines available (investment: $15,000-$30,000)

Reduces assembly time to 3-5 seconds per box

ROI typically achieved within 8-12 months for high-volume operations

Real-World Case Study

E-commerce beauty brand (anonymized):

Switched from rigid to foldable boxes in Q3 2023

Volume: 15,000 boxes/month

Hired 1 part-time assembler (4 hours/day)

First-year results: Freight savings: $42,000

Warehouse savings: $18,000

Assembly labor cost: $7,200

Net Savings: $52,800 (86% of projected savings realized)

Bonus benefit: Reduced damaged shipments by 15% (flatter packages less prone to carrier mishandling)

📦 In-Stock Catalog Advantages

1. Speed to Market

Lead time: 3-5 business days (China to major ports)

Express shipping: 5-7 days door-to-door available

No MOQ: Order 20 boxes (1 carton) for product testing

Ideal for: New product launches, seasonal tests, small batch gifting

2. Cost Structure

Unit prices: 30-40% lower than custom orders (economies of scale)

No setup fees: Zero tooling, die-cutting, or plate costs

Transparent pricing: Online price calculator available

Budget certainty: Fixed costs enable accurate retail pricing

3. Risk Mitigation

Sample before commitment: Order 1 carton to test market response

No artwork delays: Skip design approval cycles

Immediate availability: 60,000 daily production capacity buffer

📦 In-Stock Limitations

Fixed color schemes (black, gold, silver, blue common stock colors)

Standard sizes (may not fit oversized products)

No logo customization (blank boxes only)

Limited to 7-12 style variations in catalog

📦 Full Custom Development Path

Phase 1: Design Consultation (Day 0-3)

Submit product dimensions, brand guidelines, target price point

Receive 3D structural mockup + material recommendations

Color matching via Pantone reference (physical swatch mail optional)

Phase 2: Sampling (Day 4-10)

Physical blank sample: $30-50 (structure validation)

Printed sample with artwork: $100-150 (full proof)

Revisions: 1-2 rounds included, typically sufficient

Phase 3: Tooling & Production (Day 11-25)

Die-cutting tools fabrication: $150-$400 (one-time, reusable)

Print plate production: $100-$200 per color (for offset printing)

First production run: 7-15 days depending on quantity

📦 MOQ Requirements

Logo printing only: 500 pcs minimum

Custom size + printing: 1,000 pcs minimum

Complex finishing (embossing + foil): 2,000 pcs minimum

Rationale: Setup costs amortize across larger runs

📦 Hybrid Approach: Stock Box + Custom Inserts

Many B2B clients combine in-stock boxes with custom-printed inserts:

Order stock foldable boxes (fast, low cost)

Design custom paperboard insert with branding

Insert MOQ: 500 pcs (lower than full box customization)

Total timeline: 10-12 days vs. 25+ for fully custom

Cost: 60% of full custom price

📦 Decision Framework

Choose Stock if:

Volume <1,000 units/year

Need within 7 days

Neutral packaging acceptable

Cost-sensitive project

Standard sizes work for your product

Choose Custom if:

Volume >2,000 units/year

3+ weeks timeline acceptable

Logo essential for brand recognition

Quality/brand differentiation focus

Unique dimensions required

📦 Repeat Order Economics

After initial custom tooling investment:

2nd order pricing: 15-20% lower (no setup fees)

3rd+ orders: Match or beat stock pricing at 5,000+ volume

Tooling lifespan: 50,000-100,000 boxes (stored at factory)

📦 Core Material Engineering

Rigid Board Specifications:

Base material: Greyboard/Chipboard core

Density range: 600 GSM – 2000 GSM (varies by box size/purpose)

600-1000 GSM: Small boxes (<15cm), light products

1200-1500 GSM: Medium boxes, general gifting

1800-2000 GSM: Wine boxes, heavy items (up to 3kg)

Wrapping Paper Specifications:

Outer layer: 157-300 GSM coated art paper

Printing substrate: Suitable for offset, digital, or screen printing

Adhesive: EVA hot-melt glue (heat-activated, remains flexible)

Magnetic Components:

Type: Neodymium magnets (N35-N42 grade)

Dimensions: 8mm x 2mm or 12mm x 2mm (standard)

Holding force: 0.8-1.5 kg per magnetic contact point

Quantity per box: 4-8 pieces depending on closure design

Placement: Embedded between board layers, not surface-mounted

📦 Fold-Line Engineering

Critical to longevity:

Creasing depth: 70-80% of board thickness

Crease width: 0.8-1.2mm (prevents cracking)

Fiber direction: Aligns with fold lines to reduce stress

Reinforcement: Double-layer lamination at corners (high-stress areas)

📦 Quality Testing Standards

1. Fold Cycle Test

Standard: 50 fold/unfold cycles without structural failure

Premium spec: 100 cycles (for reusable luxury packaging)

Failure indicators: Delamination, corner split, magnet detachment

2. Drop Test

Empty box: 1.2m drop onto concrete, 6 orientations

Loaded box: 0.8m drop with typical product weight

Pass criteria: No corner crush, closures remain functional

3. Compression Test

Stacking simulation: 5kg top-load for 72 hours

Measurement: <5mm height deformation acceptable

Relevant for: Warehouse stacking, retail shelf compression

4. Surface Durability

Abrasion test: 500 cycles (Taber abraser method)

Lamination adhesion: Tape peel test (no delamination)

Print fade: 24-hour UV exposure (color shift <5%)

📦 Sustainability Certifications

FSC Certified Paper: Sourced from responsibly managed forests

Recycled Content Options: 30-80% post-consumer waste paperboard

Recyclability: 100% curbside recyclable (magnets removable by consumers)

Biodegradability: Paper components decompose within 90 days in industrial composting

📏 Dimensional Planning Formula

Product Dimension + Required Clearance = Internal Box Dimension

📏 Clearance Standards by Product Type

Rigid items (electronics, bottles):

Side Clearance: 3-5mm per side

Top/Bottom Clearance: 5-10mm

Reasoning: Prevents rattling, allows easy insertion

Soft goods (textiles, plush):

Side Clearance: 10-15mm per side

Top/Bottom Clearance: 10-20mm

Reasoning: Compression tolerance, folding space

Fragile items (glass, ceramics):

Side Clearance: 8-12mm per side + foam

Top/Bottom Clearance: 15-25mm + foam

Reasoning: Impact absorption zone

Cosmetic sets (multiple items):

Side Clearance: 5-8mm per item + dividers

Top/Bottom Clearance: 10-15mm

Reasoning: Divider thickness + settling space

⚠️ Common Sizing Mistakes

Mistake 1: Over-sizing syndrome

“I want extra space for perceived value”

Reality: 30%+ empty space signals cheap filler, not luxury

Fix: Product should occupy 60-75% of internal volume

Mistake 2: Exact-fit trap

Measuring product, ordering box to exact dimensions

Reality: Insertion friction, manufacturing tolerance issues

Fix: Always add minimum 3mm per dimension

Mistake 3: Ignoring insert thickness

Calculating based on product only

Reality: EVA foam (5-10mm), paperboard dividers (2-4mm) consume space

Fix: Mock-up with actual insert materials before finalizing

🔧 Custom Sizing Process

If stock sizes don’t fit:

Measure product in 3 dimensions (L x W x H in mm)

Add clearance (use standards above)

Consider insert material thickness

Add 2-3mm manufacturing tolerance

Submit to factory for structural feasibility check (free service)

📦 Size Optimization Benefits

Right-sized packaging reduces:

Material costs: 15-25%

Shipping volume & cost

Warehouse space requirements

Handling damage risk

This packaging product is designed to meet international quality and sustainability standards while providing eco-friendly, durable packaging solutions for luxury and corporate use.

Standards & Certifications: FSC Certified Paper sourced from responsibly managed forests ensures your packaging supports sustainable forestry practices.

Recycled & Eco-friendly Materials: 30-80% post-consumer recycled paperboard, coated with eco-friendly inks; EVA hot-melt adhesive is non-toxic and flexible.

Durability & Safety Testing: Fold cycle, drop, compression, and surface abrasion tests ensure reliable packaging while maintaining premium presentation.

Recyclability & Biodegradability: Paper components decompose in industrial composting within 90 days; magnets are removable for proper recycling. More info on industrial composting: Industrial Composting Standards.

Sustainable Business Practices: Right-sized foldable boxes reduce material and shipping usage, minimizing carbon footprint. This aligns with global sustainability goals: UN Sustainable Development Goals.