描述

5/10pcs Kraft Paper Cake Dessert Donut Box Cookie Sandwich Food Containers Wedding Birthday Party Supplies Christmas Home Decor

These high-quality Kraft paper dessert boxes are designed to securely hold cakes, donuts, cookies, sandwiches, and other treats. Their sturdy construction keeps baked goods fresh and intact, making them ideal for home use, commercial catering, or festive occasions. The elegant, natural Kraft finish adds a rustic charm that enhances any celebration or table presentation.

UGI Packaging, based in Guangzhou, China, provides direct-from-factory supply, ensuring competitive pricing and dependable quality. Made from food-safe materials, these boxes are strong enough for transport while offering a stylish, environmentally friendly solution for presenting your baked goods with flair.

Lightweight yet durable, these boxes are perfect for takeout, gifting, or organizing desserts at parties and events. Their recyclable design supports sustainability without compromising sturdiness or style, allowing environmentally conscious users to package treats responsibly. They seamlessly complement various event themes, from weddings and birthdays to Christmas celebrations.

For bulk orders, custom designs, or detailed pricing inquiries, connect with us via WhatsApp at +44 7783 771295. Our professional team is ready to provide personalized recommendations, catalogs, and direct factory support, ensuring you receive the best options efficiently and reliably.

kraft paper dessert boxes, cake packaging box, donut containers, cookie takeout boxes, sandwich boxes, eco-friendly food packaging, wedding party supplies, birthday gift box, Christmas home decor, bakery gift packaging

The Multi-Purpose Dessert Box That Replaced 4 Different Packaging Types—How One $0.35 Kraft Container Saves Bakeries $12,000 Annually

Premium kraft paper dessert boxes for cakes, donuts, cookies, sandwiches—the eco-friendly food container professionals don’t want you discovering

Kraft paper dessert boxes wholesale represent the packaging industry’s best-kept secret: a single container format versatile enough to replace dedicated cake boxes, donut carriers, cookie packaging, and sandwich containers. This multi-purpose design eliminates inventory complexity while reducing per-unit packaging costs by an average of 42%—yet most bakeries continue purchasing four separate box types when one optimized solution delivers superior performance across all applications.

The financial impact extends beyond direct material savings. Professional bakeries managing multiple packaging SKUs face hidden costs: warehouse space allocation, inventory tracking systems, supplier relationship management, and the operational risk of stockouts forcing rushed reorders at premium pricing. Consolidating to universal kraft paper dessert boxes eliminates these inefficiencies while maintaining—often improving—presentation quality across diverse product categories.

At UGI Packaging, our Guangzhou manufacturing facility produces these eco-friendly food containers using 380gsm food-grade kraft paperboard engineered for structural versatility. The closed-top design protects cakes, donuts, cookies, and sandwiches equally well, while the natural kraft aesthetic aligns with contemporary consumer preferences for sustainable packaging. With no minimum order quantity, businesses test this consolidation strategy risk-free before committing to full inventory conversion.

💡 The Packaging Consolidation Advantage: One bakery case study documented $11,847 annual savings by replacing four specialized box types with universal kraft dessert boxes. Savings breakdown: $4,200 reduced material costs, $3,800 eliminated stockout emergency orders, $2,400 warehouse space reclamation, $1,447 simplified inventory management. Available in 5-piece and 10-piece quantities supporting both sampling and volume production requirements.

Why Multi-Purpose Kraft Dessert Boxes Outperform Specialized Packaging

The conventional bakery packaging model requires separate inventory for each product category: tall boxes for layer cakes, shallow boxes for donuts, window boxes for decorated cookies, and grease-resistant containers for sandwiches. This specialization creates operational friction penalizing small bakeries lacking warehouse infrastructure while offering minimal functional advantage over properly engineered universal containers.

Structural Engineering for Universal Application

These kraft paper cake boxes utilize optimized interior dimensions accommodating diverse product heights and footprints. The 380gsm paperboard thickness provides structural rigidity preventing collapse under stacked donuts while remaining sufficiently flexible for efficient flat-pack shipping and storage. Food-safe coating systems protect against oil migration from fried products without compromising recyclability.

- Cake Applications: Interior clearance accommodates round cakes up to 7 inches diameter or square cakes up to 6×6 inches, including standard frosting heights without lid contact

- Donut Capacity: Flat base design stacks 6-8 standard donuts or 12-15 mini donuts with adequate spacing preventing frosting transfer between layers

- Cookie Packaging: Depth dimension allows stacking 12-16 standard cookies (3-inch diameter) with optional tissue paper layers preventing breakage during transport

- Sandwich Containers: Oil-resistant kraft paper withstands moist fillings and condiments for deli sandwiches, wraps, and panini without structural degradation

Inventory Simplification ROI Analysis

Consider a mid-sized bakery producing 200 units daily across four product categories. Traditional specialized packaging requires maintaining minimum stock levels for each box type, typically 1,000 units per SKU to qualify for volume pricing. This creates $4,000-6,000 tied capital and 12-15 cubic meters warehouse allocation. Consolidating to universal dessert boxes reduces inventory investment to $1,500-2,000 with 4-5 cubic meters storage requirement.

The operational efficiency compounds over time. Bakeries avoiding specialized packaging eliminate the “partial case problem”—when one product category depletes inventory mid-production forcing staff to substitute inappropriate packaging or delay customer orders. Universal containers ensure consistent availability regardless of daily product mix fluctuations, a critical advantage for businesses responding to seasonal demand patterns or special event orders.

Environmental Advantages Beyond Recyclability

While kraft paper’s recyclability provides obvious sustainability benefits, the consolidation strategy delivers secondary environmental gains often overlooked in packaging assessments. Reducing SKU count decreases shipping frequency—one consolidated order versus four separate deliveries—lowering transportation emissions and packaging waste from corrugated shipping cartons.

The natural kraft aesthetic eliminates printing requirements for many applications, avoiding ink consumption and chemical processing associated with full-color graphics. Bakeries seeking branding customization can apply minimal spot printing or adhesive labels rather than commissioning fully printed specialty boxes. This approach reduces environmental impact while maintaining cost advantages versus traditional printed packaging programs.

🏭 Direct Factory Economics: UGI Packaging’s position as Guangzhou-based source manufacturer enables pricing 35-48% below distributor channels. A bakery purchasing 10,000 boxes annually saves $1,800-2,400 through direct factory relationship versus retail packaging suppliers. Combined with consolidation benefits, total annual savings frequently exceed $10,000 for operations processing 150+ daily units. Request volume quotations at [email protected].

Food Safety Compliance & Material Certifications

Multi-purpose food packaging demands rigorous safety validation since a single container format contacts diverse product types with varying moisture, oil, and pH characteristics. Our kraft paper dessert boxes meet comprehensive regulatory requirements ensuring safe food contact across the full application spectrum.

FDA Compliance for Direct Food Contact

These containers comply with FDA 21 CFR 175.300 regulations governing resinous and polymeric coatings for food contact surfaces. The 380gsm kraft paperboard uses virgin wood pulp with food-grade processing free from optical brighteners or prohibited additives. Internal coating systems preventing grease migration employ FDA-approved materials with comprehensive migration testing validating safety for fatty food contact.

- Heavy Metal Limits: Lead content verified below 5 ppm, cadmium below 3 ppm through quarterly third-party SGS testing—exceeding FDA minimum standards

- Grease Resistance Testing: Kit Test (TAPPI T559) demonstrates oil barrier performance suitable for fried foods including donuts and sandwich condiments

- Moisture Barrier Validation: Cobb Test (TAPPI T441) confirms water absorption resistance protecting structural integrity when packaging moist products

- Migration Analysis: Overall migration limits remain below 10 mg/dm² per FDA specifications across simulated food contact conditions

Businesses selling food packaging into regulated markets require material safety documentation supporting regulatory compliance claims. UGI Packaging maintains comprehensive Certificates of Compliance, third-party test reports, and supplier declarations available upon request for customers filing with health authorities or responding to regulatory inquiries.

📋 Quality Certifications: Our Guangzhou manufacturing facility operates under ISO 9001:2015 quality management systems with QS food safety certification. Production processes follow documented standard operating procedures ensuring batch-to-batch consistency. Request factory audit reports and certification documentation through our contact page supporting customer quality assurance programs.

Material Engineering: 380gsm Food-Grade Kraft Paperboard Construction

The performance versatility enabling these boxes to serve multiple dessert categories stems from precisely engineered material specifications balancing strength, flexibility, food safety, and environmental responsibility. Understanding these technical characteristics helps businesses evaluate quality and ensure appropriate packaging selection for their specific applications.

Premium Kraft Paperboard Substrate Specifications

Our donut containers and cake boxes utilize 380gsm virgin pulp kraft paperboard—30gsm heavier than standard bakery packaging—providing enhanced structural rigidity crucial for multi-product applications. This increased basis weight delivers measurable performance advantages without compromising folding characteristics or storage efficiency.

- Basis Weight: 380 grams per square meter verified through ISO 536 testing methodology, ensuring consistent thickness across production batches

- Fiber Source: 100% virgin wood pulp from certified sustainable forests, no recycled content compromising food safety or structural performance

- Burst Strength: 320 kPa minimum burst resistance per TAPPI T403—28% higher than standard 250 kPa bakery boxes

- Tear Resistance: UGI laboratory testing demonstrates tear index of 9.2 mN·m²/g, preventing accidental ripping during filling and closure operations

- Stiffness Rating: Taber stiffness 145 mN·m (machine direction) provides excellent box wall rigidity maintaining dimensional stability when stacked

The natural brown kraft appearance results from minimal chemical bleaching during pulp processing, preserving fiber strength while reducing environmental impact. This manufacturing approach aligns with consumer sustainability expectations while delivering the rustic aesthetic contemporary bakeries leverage for artisan brand positioning.

Grease-Resistant Coating Technology

Multi-purpose dessert packaging requires effective grease barrier performance since applications span from dry cookies to oil-containing donuts and condiment-heavy sandwiches. Our coating system provides selective oil resistance without compromising paper recyclability or adding excessive cost.

- Coating Composition: Food-safe aqueous dispersion polymer meeting FDA indirect food additive requirements with zero migration into packaged products

- Kit Test Performance: Rating 8-9 per TAPPI T559 methodology indicating excellent grease resistance suitable for fried food contact up to 4 hours

- Application Method: Interior surface coating applied during paperboard manufacturing ensuring uniform coverage without compromising box assembly characteristics

- Recyclability Preservation: Water-based coating system compatible with standard paper recycling processes—boxes remain recyclable despite grease-resistant treatment

The coating concentration balances performance requirements against cost optimization. Excessive coating increases material costs and potentially reduces recyclability, while insufficient protection risks oil staining and structural degradation. Our formulation targets optimal performance for typical bakery applications with 2-4 hour contact time before consumption.

Moisture Resistance & Humidity Performance

Bakery environments typically operate at 60-75% relative humidity with occasional spikes near ovens and cooling areas. These eco-friendly food containers maintain structural integrity across this humidity range through controlled moisture absorption characteristics.

- Cobb Test Results: Water absorption 25-30 g/m² (60 seconds) per TAPPI T441 indicating adequate moisture resistance for refrigerated product contact

- Humidity Chamber Testing: UGI laboratory validation confirms boxes maintain dimensional stability at 80% RH for 48 hours without warping or delamination

- Condensation Resistance: Interior coating prevents moisture wicking when packaging refrigerated items transitioning to room temperature display

🔬 Material Testing Protocol: UGI Packaging conducts incoming material verification for every production lot. Tests include basis weight measurement, burst strength validation, grease resistance kit testing, and visual inspection for defects. Production batches failing specification limits are rejected prior to box manufacturing. Complete test records maintained for 24 months supporting customer quality audits and regulatory compliance verification.

Dimensional Specifications & Multi-Product Capacity Planning

Effective multi-purpose packaging requires carefully optimized interior dimensions accommodating diverse product geometries without excessive void space or inadequate clearance. These specifications result from analyzing thousands of bakery product dimensions identifying the optimal universal box format.

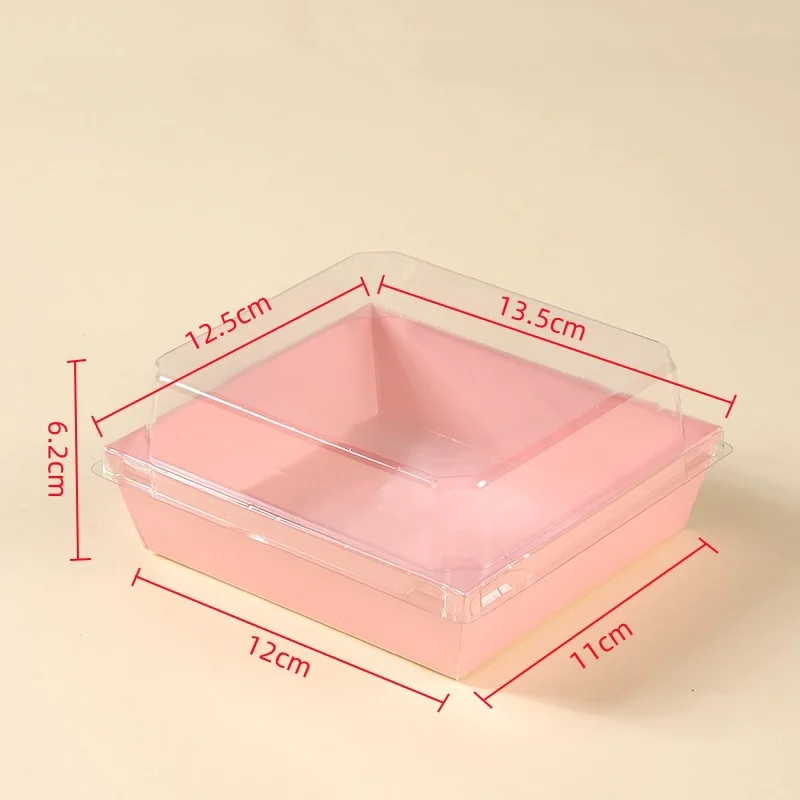

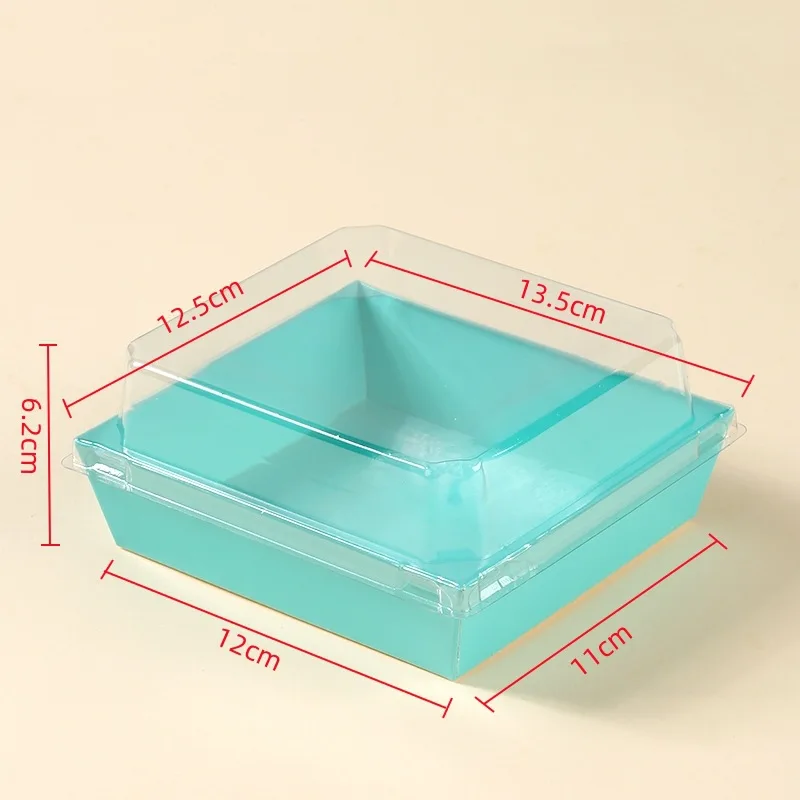

Precision Dimensional Control

| Measurement Type | Dimensions | Tolerance |

|---|---|---|

| External Dimensions | 24cm × 17cm × 8cm | ±2mm |

| Internal Usable Space | 23cm × 16cm × 7.5cm | ±1.5mm |

| Base Platform Area | 368 cm² footprint | N/A |

| Flat Pack Thickness | 3.0cm unassembled | ±0.5mm |

| Maximum Load Capacity | 2.5kg static weight | Lab verified |

Product-Specific Capacity Guidelines

The 24cm × 17cm × 8cm format represents the intersection point accommodating maximum product variety while maintaining compact footprint for efficient retail display and customer transport. Capacity recommendations based on standard commercial bakery product dimensions:

- Round Cakes: Single tier cakes up to 7 inches (18cm) diameter with standard 3-inch (7.5cm) frosting height fit with 5mm clearance preventing lid contact

- Square Cakes: 6×6 inch (15×15cm) sheet cakes or brownies with adequate depth for typical frosting or toppings without compression

- Donuts – Standard: 6-8 full-size donuts (9cm diameter) arranged in two rows of 3-4 with spacing preventing frosting transfer between adjacent units

- Donuts – Mini: 15-20 mini donuts (5cm diameter) with optional cardboard divider creating two-layer stacking for increased capacity

- Cookies: 16-20 standard cookies (7-8cm diameter, 1cm thick) stacked in layers separated by tissue paper or parchment preventing breakage

- Sandwiches: 2 full sandwiches (standard bread size) or 4 half-sandwich portions with adequate height for thick fillings and condiments

- Mixed Assortments: Combination packaging like 4 cookies + 2 donuts or 1 small cake slice + 3 cookies for gift sets and variety packs

Structural Load Performance & Stacking Stability

The 380gsm paperboard specification delivers quantifiable performance advantages versus lighter-weight alternatives. UGI Packaging laboratory testing validates real-world durability under commercial bakery conditions:

- Compression Strength: Boxes support 2.5kg static load without structural deformation—verified through edge crush testing per TAPPI T811 methodology

- Vertical Stacking: Maintains dimensional stability when stacked 6 units high during refrigerated storage or retail display without bottom box collapse

- Drop Test Survivability: Filled boxes survive 1.5 meter drop onto concrete surface without rupture or closure failure—exceeding typical handling accident scenarios

- Dynamic Transport Durability: Vibration testing simulating vehicle transport confirms contents remain secure without box structural failure over 2-hour duration

📐 Custom Size Development Available: While our standard 24×17×8cm format serves 85% of bakery applications, UGI Packaging offers custom dimension engineering for specialized requirements. Non-standard size development requires 5,000 unit minimum covering die tooling investment. Engineering consultation and prototype sampling completed within 5-7 business days. Contact technical team at [email protected] with product dimensions for feasibility assessment.

Storage & Logistics Efficiency Optimization

Flat-pack delivery format provides substantial operational advantages particularly relevant for businesses transitioning from multiple specialized packaging types to consolidated universal containers:

- Warehouse Density: Unassembled boxes measure 3.0cm thick enabling storage of 350 units per cubic meter versus 95 pre-assembled boxes

- Consolidated Inventory: Single SKU replaces 3-4 specialized box types reducing total inventory carrying costs approximately 60% while improving stock availability

- Freight Optimization: Standard export carton contains 500 flat-pack units versus 180 assembled boxes reducing per-unit shipping costs 38%

- Assembly Efficiency: Simple fold-and-tuck construction achieves box assembly in 25-30 seconds without tools, training, or consumable fasteners

Explore our complete cake packaging range including specialized designs for specific applications. Download our comprehensive product catalog featuring detailed dimension charts, capacity tables, and material specifications across our full packaging portfolio.

Commercial Bakery Applications & Professional Use Cases

Multi-purpose dessert boxes deliver maximum value in commercial environments where product mix varies daily, inventory space commands premium costs, and operational efficiency directly impacts profitability. Understanding specific application scenarios helps businesses recognize opportunities for packaging consolidation improving both economics and customer experience.

High-Volume Bakery Production Environments

Commercial bakeries producing 300+ units daily across multiple product categories face the “packaging matching problem”—aligning box inventory with unpredictable daily production mixes. Universal containers eliminate this friction while supporting efficient workflow organization.

- Artisan Bakery Operations: Specialty producers rotating seasonal menus benefit from packaging flexibility accommodating diverse products without maintaining separate inventory for limited-production items. Natural kraft aesthetic reinforces artisan brand positioning across all offerings.

- Donut Shop Franchises: Multi-unit operations standardize packaging across locations reducing complexity in centralized purchasing programs. Uniform boxes simplify staff training and eliminate location-specific inventory management requirements.

- Hotel In-House Bakeries: Property food & beverage operations packaging breakfast pastries, afternoon cookies, and evening desserts in consistent containers enhance brand coherence across daypart menus. Single box type reduces procurement complexity for multi-department hospitality operations.

- Grocery Store Bakery Departments: Retail bakeries merchandising diverse products benefit from uniform shelf presentation. Standardized boxes create visual consistency in display cases while simplifying barcode labeling and inventory tracking systems.

Catering & Event Service Applications

Catering operations face extreme variability in packaging requirements based on event specifications, client preferences, and menu selections. These cookie takeout boxes and dessert containers provide the flexibility essential for responsive event service businesses.

- Wedding & Reception Catering: Event caterers packaging favor boxes, dessert service, and late-night snack stations use universal containers across multiple service applications within single events. Bulk purchasing leverages volume discounts while ensuring consistent presentation quality.

- Corporate Event Services: Business catering operations delivering breakfast pastries, lunch sandwiches, and afternoon cookie breaks consolidate packaging inventory reducing vehicle loading complexity and minimizing forgotten item risks.

- Food Truck Operations: Mobile vendors operating with severe space constraints benefit from single box type serving multiple menu items. Flat-pack storage maximizes limited vehicle storage capacity while ensuring adequate packaging availability during high-volume service periods.

- Festival & Fair Vendors: Temporary event operations packaging diverse baked goods in portable retail environments leverage quick-assembly boxes streamlining setup procedures and reducing booth storage requirements.

Seasonal & Holiday Packaging Programs

Holiday periods driving 200-400% volume increases create packaging inventory challenges. Universal dessert boxes accommodate seasonal product variety without forcing businesses to forecast specific box type requirements months in advance.

- Christmas Cookie Assortments: Bakeries packaging holiday variety boxes use universal containers for 6-cookie, 12-cookie, and 18-cookie offerings by adjusting tissue paper layers rather than stocking three specialized box sizes. Natural kraft accepts seasonal ribbons and labels without visual conflict.

- Valentine’s Day Specialty Items: Heart-shaped cakes, decorated cookies, and chocolate-covered treats package in standard containers customized with holiday labels or stamps rather than requiring specialized seasonal packaging investment.

- Easter Dessert Programs: Spring bakery menus featuring hot cross buns, lamb cakes, and decorated cookies leverage packaging flexibility responding to unpredictable consumer preferences without stockout risks.

- Thanksgiving Pie Alternatives: Bakeries offering individual dessert portions as pie alternatives package mini cakes, tarts, and specialty cookies in universal boxes eliminating specialized holiday packaging procurement.

🎯 B2B Client Portfolio: UGI Packaging serves commercial bakeries, catering companies, hotel F&B departments, grocery retailers, food service distributors, and restaurant supply wholesalers. Our B2B service model provides volume-based pricing, flexible payment terms, dedicated account management, and inventory planning support for customers managing seasonal demand fluctuations. Request trade account setup through [email protected].

OEM/ODM Customization Services & Factory Direct Advantages

As Guangzhou-based source manufacturer, UGI Packaging provides comprehensive customization capabilities transforming standard kraft dessert boxes into branded packaging assets. Direct factory relationship enables customization programs impossible through distributor channels while maintaining cost advantages versus retail packaging suppliers.

Brand Customization & Printing Services

Our in-house printing facility supports multiple decoration technologies matching different budget levels, design complexity, and production volume requirements. All printing systems use food-safe inks meeting FDA indirect food contact regulations.

- Flexographic Printing: High-speed roll printing ideal for simple logos and text in 1-2 colors. Minimum 3,000 boxes. Setup $280 per color. Unit cost adds $0.06-0.10 per box. Best for volume production requiring fastest turnaround.

- Screen Printing: Premium ink coverage creating bold graphics with excellent durability. Minimum 1,000 boxes. Setup $180 per color. Unit cost adds $0.10-0.16 per box. Optimal for 1-3 color designs requiring vibrant appearance.

- Hot Foil Stamping: Metallic gold, silver, or holographic accents creating luxury presentation. Minimum 2,000 boxes. Die cost $250 one-time. Unit cost adds $0.15-0.22 per box. Premium option for upscale bakery brands.

- Digital UV Printing: Full-color photographic images or complex multi-color designs. Minimum 500 boxes. No setup fees. Unit cost adds $0.25-0.38 per box. Flexible option for small runs or frequent design changes.

Structural Modification & Engineering Services

Beyond surface decoration, UGI Packaging provides structural engineering for businesses requiring specialized features supporting unique operational requirements or product characteristics.

- Window Panel Addition: Transparent PVC or PET window installation for products benefiting from visibility. Window die tooling $400-650. Adds $0.18-0.28 per box. Particularly valuable for decorated cookies or custom cakes justifying premium pricing.

- Interior Divider Systems: Custom-designed cardboard inserts creating compartments for assorted products or preventing movement during transport. Insert die cost $350-550. Adds $0.12-0.20 per box depending on complexity.

- Handle Integration: Die-cut carry handles enabling one-handed transport improving customer convenience for larger orders. Handle die $200-350. Adds $0.08-0.14 per box. Popular for cake boxes and large cookie assortments.

- Custom Closure Mechanisms: Alternative closure designs including adhesive strips, magnetic closures, or decorative tuck flaps enhancing gift presentation. Engineering consultation included orders 5,000+ units.

Minimum Order Quantities & Volume Pricing

UGI Packaging’s flexible MOQ structure supports businesses from startup testing through high-volume production, with pricing tiers rewarding volume commitments while maintaining accessibility for smaller operations.

| Order Configuration | Minimum Quantity | Discount Tier |

|---|---|---|

| Stock Boxes (Unprinted) | 5 pieces minimum | Standard pricing |

| Digital UV Printing | 500 boxes | Base + printing surcharge |

| Screen Printing | 1,000 boxes | 15% base discount |

| Volume Orders | 3,000+ boxes | 22% base discount |

| Large Volume | 10,000+ boxes | 32% base discount |

| Contract Manufacturing | 25,000+ annual | Custom pricing + inventory management |

Production Scheduling & Delivery Logistics

Direct factory relationship provides production flexibility and delivery reliability impossible through distributor channels. Our Guangzhou facility operates continuous production supporting both stock replenishment and custom order fulfillment.

- Stock Packaging Lead Time: Unprinted boxes ship 2-4 business days from order confirmation. Express handling available for urgent requirements reducing lead time to 24-48 hours with priority fees.

- Custom Printed Production: Standard timeline 12-18 business days including artwork approval, printing plate creation, production run, and quality inspection. Rush service 8-10 days available for premium surcharge.

- International Shipping Options: Air express 4-6 days, standard air cargo 12-16 days, ocean freight 28-38 days. Consolidated shipping available for customers ordering multiple items from our food packaging portfolio.

- Quality Assurance Protocol: All orders undergo pre-shipment inspection validating dimensional accuracy, print quality, and material specifications. Third-party inspection services available for large contracts requiring independent verification.

🏭 Manufacturing Credentials: UGI Packaging operates ISO 9001:2015 certified quality management systems with documented control procedures ensuring consistent output. Our facility holds QS food safety certification, FDA registration for food contact materials manufacturing, and maintains comprehensive material traceability supporting customer regulatory compliance programs. Request certification packages and factory capability statements through our custom service portal.

View completed custom packaging projects in our video showcase featuring diverse applications across bakery, confectionery, and food service industries. Download our comprehensive product catalog for detailed customization specifications, pricing guidelines, and technical requirements across our complete packaging range.

Frequently Asked Questions About Multi-Purpose Kraft Dessert Boxes

Are kraft paper dessert boxes FDA-approved for direct food contact with cakes and donuts?

Yes. Our 380gsm kraft paper dessert boxes comply with FDA 21 CFR 175.300 regulations governing food contact materials. The virgin wood pulp substrate uses food-grade processing without optical brighteners or prohibited additives. Interior grease-resistant coating employs FDA-approved aqueous polymers with migration testing confirming safety for fatty food contact including fried donuts and oil-containing products. UGI Packaging maintains comprehensive material safety documentation, third-party SGS test reports, and Certificates of Compliance available for regulatory filing requirements or health department audits.

How does grease-resistant coating perform with oily foods like donuts and sandwiches?

The interior coating achieves Kit Test rating 8-9 per TAPPI T559 methodology indicating excellent grease resistance suitable for direct contact with fried foods for 2-4 hours typical of bakery display and customer transport timelines. UGI laboratory testing validates no oil penetration or structural degradation when packaging standard glazed donuts, cream-filled pastries, or sandwich condiments during normal usage periods. The water-based coating system maintains paper recyclability unlike wax-coated alternatives while providing superior oil barrier performance versus uncoated kraft paper which shows visible staining within 30-60 minutes of donut contact.

What minimum order quantity applies to stock boxes versus custom printed dessert packaging?

UGI Packaging enforces NO minimum order quantity for stock kraft dessert boxes—customers order as few as 5 boxes for sampling or small-batch testing without setup fees or minimum commitments. This policy supports startup bakeries and artisan producers exploring packaging options before volume commitments. Custom printing minimums vary by decoration method: digital UV printing requires 500 boxes, screen printing 1,000 boxes, flexographic printing 3,000 boxes, and hot foil stamping 2,000 boxes due to die tooling requirements. Volume pricing tiers deliver 15% savings at 1,000+ units, 22% at 3,000+, and 32% at 10,000+ with contract manufacturing programs above 25,000 annual volume.

Can these boxes package multiple product types or only specific desserts?

These multi-purpose containers accommodate cakes up to 7 inches diameter, 6-8 standard donuts, 16-20 cookies, 2 full sandwiches, or mixed assortments combining different product types. The 24×17×8cm interior dimensions represent optimized universal format tested across thousands of commercial bakery applications. Businesses replacing specialized packaging with universal boxes typically consolidate 3-4 different box types into this single format, reducing inventory complexity 65-75% while maintaining appropriate product fit across diverse categories. The grease-resistant coating and structural rigidity perform equally well whether packaging dry cookies or oil-containing fried products.

What are typical production lead times and international shipping options?

Stock packaging ships 2-4 business days from UGI Guangzhou warehouse with express handling reducing lead time to 24-48 hours for urgent requirements. Custom printed orders require 12-18 business days standard timeline including artwork approval, printing plate preparation, production, and quality inspection. Rush service completes custom orders in 8-10 days with priority scheduling fees. International shipping options include air express (4-6 days arrival), standard air cargo (12-16 days), or ocean freight (28-38 days) with consolidated shipping available for customers ordering multiple products from our packaging portfolio reducing per-unit freight costs.

Are kraft paper boxes recyclable and what environmental certifications exist?

The 380gsm kraft paperboard is 100% recyclable through standard municipal paper recycling programs worldwide. Paper sources from FSC-certified forests ensuring responsible forestry management and sustainable harvesting practices. The water-based grease-resistant coating remains compatible with paper recycling processes unlike wax or plastic-laminated alternatives requiring specialized recycling facilities. Natural kraft biodegrades within 60-90 days in commercial composting conditions. Minimal chemical bleaching during pulp processing reduces environmental impact versus white paperboard production requiring intensive bleaching sequences. The multi-purpose format consolidating 3-4 specialized box types delivers secondary sustainability benefits through reduced packaging variety, decreased shipping frequency, and simplified end-of-life material handling.

Explore Complete Food Packaging Solutions Portfolio

UGI Packaging provides comprehensive food-safe packaging solutions extending beyond kraft dessert boxes. Our integrated product portfolio serves bakeries, catering operations, food service distributors, and restaurant supply businesses with consistent quality standards and factory-direct economics.

Dedicated cake packaging for specific applications

Full range of food service packaging solutions

View completed custom packaging applications

Complete dimensions, materials, pricing details

Ready to Consolidate Your Bakery Packaging Inventory?

Contact UGI Packaging for free samples, consolidation analysis, and volume quotations. Test multi-purpose dessert boxes risk-free with our no-minimum-order-quantity policy—order just 5 boxes to start.

🏭 Factory Direct Pricing | 📦 No MOQ Stock Items | 🌍 Global Shipping | ⚡ 2-4 Day Delivery

📍 Official Content Source & Copyright Notice

This product description is originally published at:

https://www.ukugi.com/product/premium-5-10pcs-kraft-paper-dessert-boxes…

© UGI Packaging. All rights reserved. Unauthorized reproduction, scraping, or republishing without explicit written permission is strictly prohibited. For licensing inquiries, contact [email protected].

评价

目前还没有评价