描述

Digital Label

A variety of digital sticker options are available, allowing full customization based on your own design. Starting from just 1 piece with a quick turnaround time, they’re ideal for both small and large-scale needs.

Digital stickers are produced using advanced digital printing technology, offering a combination of high efficiency and cost-effectiveness. They feature excellent print resolution, vivid color output, sharp details, and flexible customization options. Since the process doesn’t require traditional plate-making, it enables fast production tailored to specific requirements—perfect for short-run orders and rapid delivery while keeping costs low.

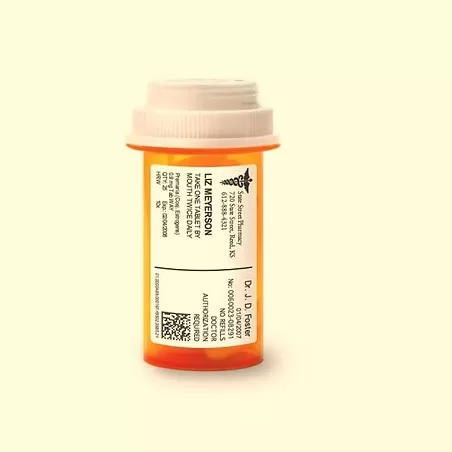

- Essential Information Delivery – Primarily used for conveying essential information, such as product packaging specifications, shipping details, barcodes, batch numbers, and compliance marks—ensuring clarity and traceability across the supply chain.

- Durable Digital Printing – Printed in continuous rolls, using high-resolution digital technology with protective lamination that resists oil, moisture, and indoor wear—ideal for warehouses, logistics, and retail packaging environments.

- Optimal Thickness Design – Typically made thinner, around 3–4mm in thickness, for easier application on various flat or curved surfaces. The compact form factor also helps reduce material bulk and improve labeling efficiency.

- Function-Focused Design – Focused on function over decoration, these labels prioritize legibility and data accuracy, ensuring vital product information is delivered clearly and reliably throughout handling and transportation.

Why Choose Digital Labels?

Digital labels are high-performance printed labels created using advanced digital printing technology. Unlike traditional methods such as offset or flexographic printing, digital label printing does not require plates or molds, which means faster setup, lower cost for small batches, and greater design flexibility. This modern process allows variable data printing (such as different barcodes or serial numbers on each label), making it ideal for applications that demand precision and customization.

Our digital labels are produced on professional-grade equipment using waterproof, oil-resistant materials—typically high-quality coated paper or vinyl—paired with durable adhesives that perform well in diverse packaging environments. Whether used for product labeling, shipping, logistics, or branding, digital labels ensure crisp resolution, clear legibility, and a clean, professional appearance.

Most importantly, digital label printing enables fast turnaround times, no minimum plate fees, and the ability to edit or update designs without retooling, making it the smart choice for growing businesses, custom packaging, or frequently changing product lines.

Product Specifications:

🧾 Material: Premium paper or vinyl substrate

Ideal for a wide range of labeling needs such as product packaging, retail, shipping, or industrial use. Both paper and vinyl options are designed to handle daily handling and exposure.

📏 Thickness: 3–4mm

Provides a durable and professional feel while remaining flexible enough for smooth application on curved or flat surfaces.

✨ Finish: Matte or glossy protective coating

Choose between a sleek glossy finish for visual impact or a matte finish for a more subtle, elegant look. Both coatings offer additional resistance to scratching, oil, and moisture.

🌀 Adhesive: Permanent acrylic adhesive

Ensures a strong and secure bond to most surfaces, including cardboard, plastic, glass, and metal. Designed to withstand temperature fluctuations and humid conditions.

📦 Format: Available in roll or sheet

Compatible with standard label dispensers and printers. Rolls are perfect for automated application, while sheets are ideal for manual use or small-batch production.

📐 Size Options: Custom sizes from 1″x1″ to 8″x10″

Tailored to your specific needs, whether for small barcodes or large product labels. Easily fit your layout and design requirements.

🔢 Quantity: Available in 100 / 500 / 1000 / 5000 pcs per roll

Flexible order volumes to suit short-run custom orders or large-scale commercial packaging projects, ensuring cost-effective production.

| Size (inches) | Availability |

|---|---|

| 0.75 × 1.75 | ✓ |

| 1 × 1.5 | ✓ |

| 1 × 2 | ✓ |

| 1 × 3 (Featured) | ✓ |

| 1.5 × 2 | ✓ |

| 2 × 3 | ✓ |

| 2 × 4 | ✓ |

| 3 × 3 | ✓ |

| 3 × 5 | ✓ |

| 3.5 × 5 | ✓ |

| 4 × 4 | ✓ |

| 4 × 6 | ✓ |

🔎 More custom sizes available upon request

What You Get:

📦 Professional digital labels as per your specifications

📋 Free design proof for approval

🎨 Custom layout and information formatting

🚚 Fast turnaround and secure packaging

| Feature | Details |

|---|---|

| Material Type | Digital Print on Roll (Permanent Adhesive) |

| Film Thickness | 2.6 mil white BOPP with matte finish |

| Adhesive | 2 mil ultra-strong, adheres to any surface (even carpet) |

| Weatherproof | Waterproof & machine washable (great for fabrics) |

| Applications | Suitable for indoor and outdoor use |

| Print Quality | Vivid full-color digital printing for logos or designs |

| Temp Resistance | Rated up to 160°F |

| Durability | Augmented strength (Aug 4 rating), optional lamination available |

Business Quality Guarantee: We provide commercial-grade labels with consistent quality. 30-day satisfaction guarantee for peace of mind!

Key Advantages of digital label

Digital label printing refers to the modern process of producing labels directly from digital files, eliminating the need for printing plates or lengthy setup. This method relies on advanced computer software to interpret your label design and instantly output high-resolution prints. Unlike traditional offset methods, digital label printing requires minimal preparation. Simply upload your design file, and the printer gets to work – fast, efficient, and accurate.

🎨 Digital Label Printing Technologies

Each method offers distinct advantages depending on the application:

🖨️ Inkjet Printing

Sprays microscopic ink droplets onto materials like paper, plastic, or fabric—ideal for vibrant images and smooth gradients.

🔍 Laser Printing

Uses static electricity to transfer toner with precision, producing clean lines and crisp text—perfect for detailed designs and barcodes.

🧊 Solid Ink Printing

Uses melted solid ink sticks rather than liquid, delivering bold, saturated colors—great for high-impact visuals.

⚡ Rapid Turnaround

No need for printing plates—production starts immediately after finalizing your design, reducing lead times.

🖼️ Exceptional Print Quality

High-resolution digital output ensures sharp details, vivid colors, and consistent results directly from your design file.

🔄 Personalization Capabilities

Easily print variable data such as unique serial numbers, names, or promotional codes—ideal for marketing and tracking.

🌈 Flexible Versioning

Quickly produce multiple label variations (e.g., color changes, different SKUs or languages) without resetting the printing process.

How Digital Label Printing Works

While simpler than traditional methods, digital label printing still follows a structured and precise workflow to ensure professional quality.

🎨 Artwork Design

Designers use professional software to create high-resolution layouts with vector graphics. You can also incorporate advanced effects like foil stamping, embossing, or textured finishes at this stage.

🖥️ Pre-Press Setup

The artwork is converted into a digital print file. Key settings such as color calibration, laminate type (matte or gloss), and cutting method (laser or die-cut) are finalized.

🖨️ Printing Execution

The digital printer applies your design directly to the chosen material—typically vinyl or coated paper—delivering sharp, vibrant, and consistent results.

🔍 Post-Print Review

Each batch undergoes quality control to ensure accurate color, sharpness, alignment, and overall consistency before proceeding.

✂️ Finishing & Packaging

Labels are trimmed, slit, or rolled to fit the final application format. If labels are intended for curved or tapered surfaces, pre-forming or shaping is applied before packing and shipment.

📦 Where Is Digital Label Printing Used?

Digital Printing Serves a Wide Range of Industries and Applications:

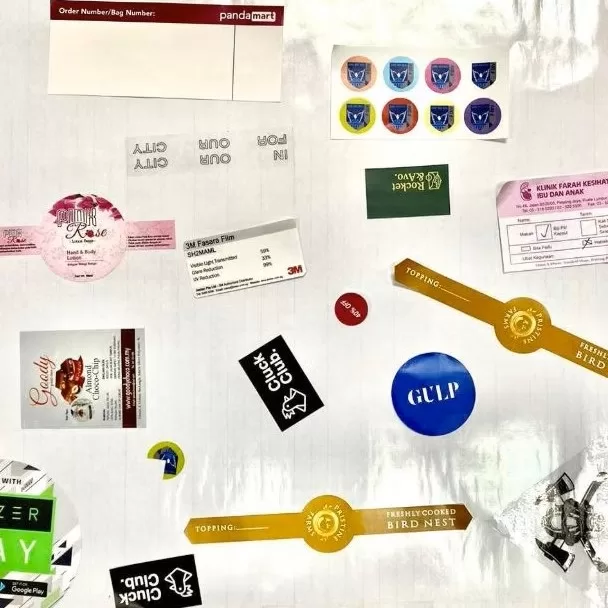

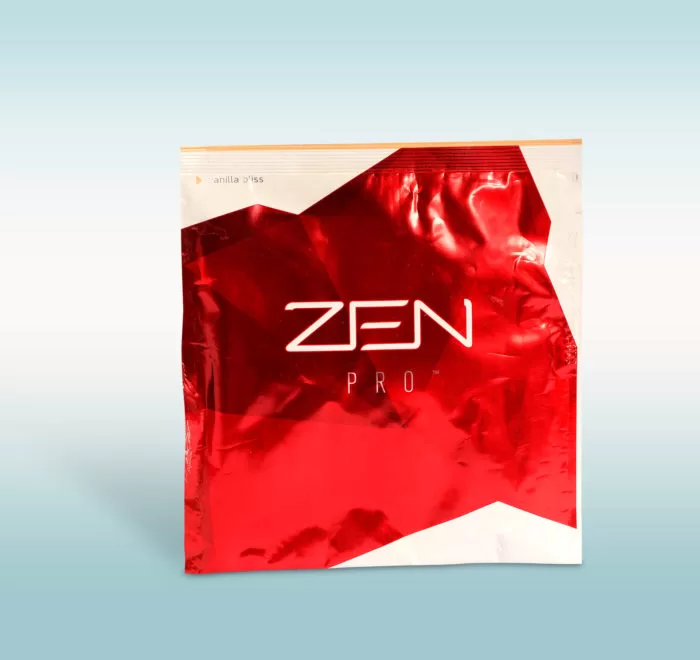

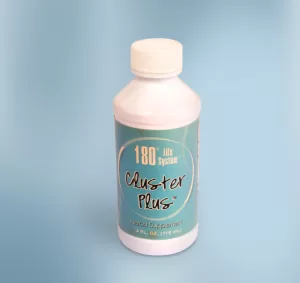

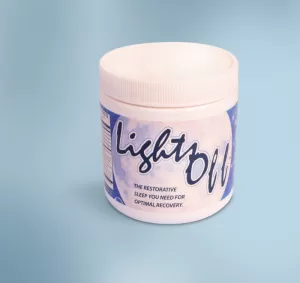

🏷️ Product Labels

Perfect for food, beverages, cosmetics, and apparel—digital printing delivers high-quality branding and required regulatory information for nearly all consumer goods.

📦 Brand Packaging

From tech gadgets to fragrance boxes, companies rely on digital labels to create packaging that reflects their unique identity and elevates shelf appeal.

🎁 Custom & Personalized Labels

Modern consumers love personalization. Digital printing allows for unique names, seasonal artwork, or individualized designs—ideal for gift packaging or limited editions.

📢 Promotional Stickers

Event giveaways, campaign decals, retail window graphics, and branded badges are all easier to produce in small or bulk runs with vivid, professional results.

⚠️ Industrial & Safety Labels

Used in warehouses, factories, and logistics, digital labels provide essential info like barcodes, safety warnings, batch IDs, and handling instructions—precise and durable for tough environments.

📦 Product Packaging & Branding – Ideal for conveying product info, logos, and barcodes with a professional finish.

🚚 Shipping & Logistics Labels – Ensure smooth delivery with durable labels for tracking, handling, and routing.

📊 Inventory Management – Organize and monitor stock efficiently with barcoded or serialized digital labels.

🍔 Food & Beverage Labeling – Waterproof and oil-resistant options perfect for bottles, jars, and takeout packaging.

🏷️ Retail Price Tags – Print clear, smudge-free prices and barcodes for shelves, garments, and consumer goods.

✉️ Address & Mailing Labels – Perfect for envelopes, parcels, and packaging—ensuring accurate, readable delivery info.

⚠️ Warning & Instruction Labels – Communicate safety instructions, cautions, or usage guidance clearly and effectively.

🚀 The Growing Impact of Digital Label Printing

Digital label printing continues to reshape the packaging world, providing unmatched flexibility, speed, and cost-efficiency. As technology evolves, the possibilities in design, material choice, and print effects only continue to grow.

Whether you’re a startup building your brand, or an established company seeking faster turnarounds, our digital label printing offers a scalable, high-quality solution for today’s dynamic market.

FAQ

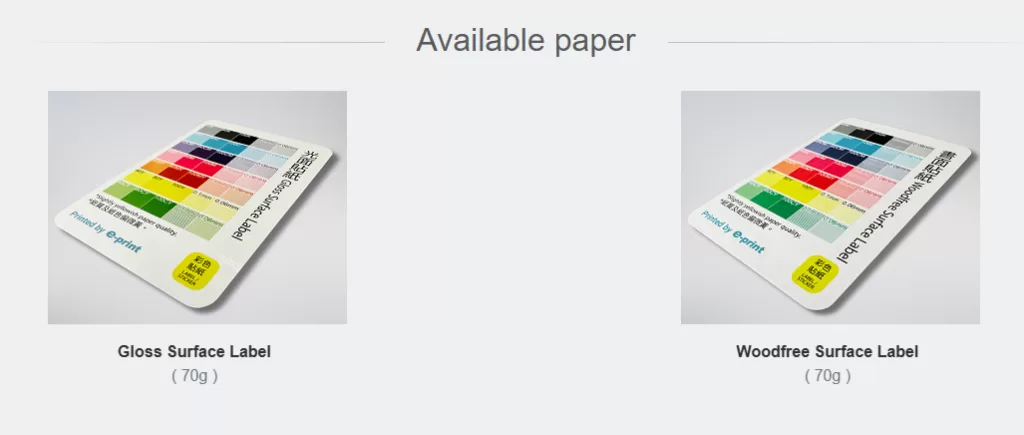

Are gloss and woodfree surface labels priced differently?

No, both gloss and woodfree options are available at the same price point. You can choose either surface finish based on your aesthetic preference or material needs without worrying about any cost difference. This makes it easy to select a style that fits your product image while keeping your budget under control.

Can I print digital stickers on both sides?

Digital stickers are limited to single-sided, full-color printing only. This ensures sharp, vibrant graphics with high resolution. The back side is reserved for adhesive application, which is why double-sided printing isn’t available for this product type.

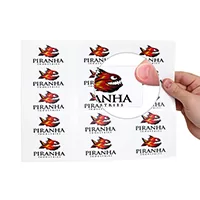

What sizes are available for digital sticker sheets?

Sticker sheets come in a fixed size of 210×297mm, equivalent to standard A4. Each sheet includes one cutting layout by default, and the finished stickers are delivered in either A4 or A5 format. Custom sizing beyond this specification is not available under the standard pricing plan.

Is there a minimum size requirement for each label on the sheet?

Yes, to ensure quality and legibility, each individual label on the sheet must be at least 25mm in size. This allows enough space for clean printing and accurate cutting, especially if your design includes text or fine details.

How many kiss-cut labels can I include on one sheet?

You can include up to 30 kiss-cut labels per sheet, depending on the design and size. Common shapes such as circles, squares (with either sharp or rounded corners), hearts, triangles, rhombuses, and trapezoids are included in the standard die-cut options. If you require custom or intricate shapes, please contact us to discuss feasibility and additional charges.

Is there a required distance between each label?

Yes, there must be at least 5mm of spacing between each label to avoid overlapping during cutting. Additionally, each label should be no narrower than 10mm to maintain structural stability and ease of peeling.

Do I need to include bleed in my artwork files?

Yes, please include a 2mm bleed on all sides of your artwork to ensure proper alignment and clean edges after cutting. This is especially important for full-background designs or artwork that reaches the edge of the sticker shape.

Where can I get more information or support?

If you have any questions about specifications, custom requests, or artwork setup, please don’t hesitate to reach out to our support team. We’re happy to assist with file checking, technical advice, and production timelines.

What is the appearance of woodfree surface paper?

Woodfree paper has a slightly yellowish or warm white tone compared to pure white gloss paper. This gives it a more natural, textured look. If you’d like to compare finishes, we recommend visiting a print shop or requesting a sample before placing your order.

Custom labels, digital printing, product labels, business labels, packaging labels, shipping labels, waterproof labels, adhesive labels, roll labels, barcode labels

评价

目前还没有评价