描述

20/28cm Transparent Gift Boxes Artificial Rose Flower Bear Packaging Box DIY PVC Clear Cake Box Wedding Birthday Decoration

Upgrade your dessert presentation with these 1/5/10pcs transparent cake transport boxes. Each box is crafted from food-safe plastic combined with a sturdy paper base, ensuring both durability and eco-friendliness. The clear walls provide a perfect view from every angle, making them ideal for showcasing cakes, breads, cheese, pastries, and cookies.

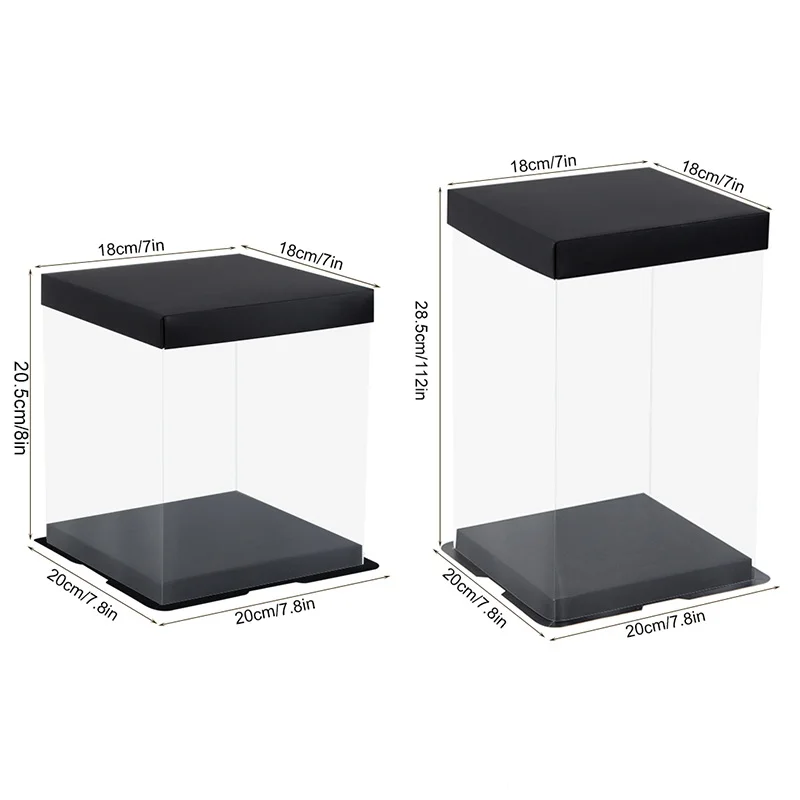

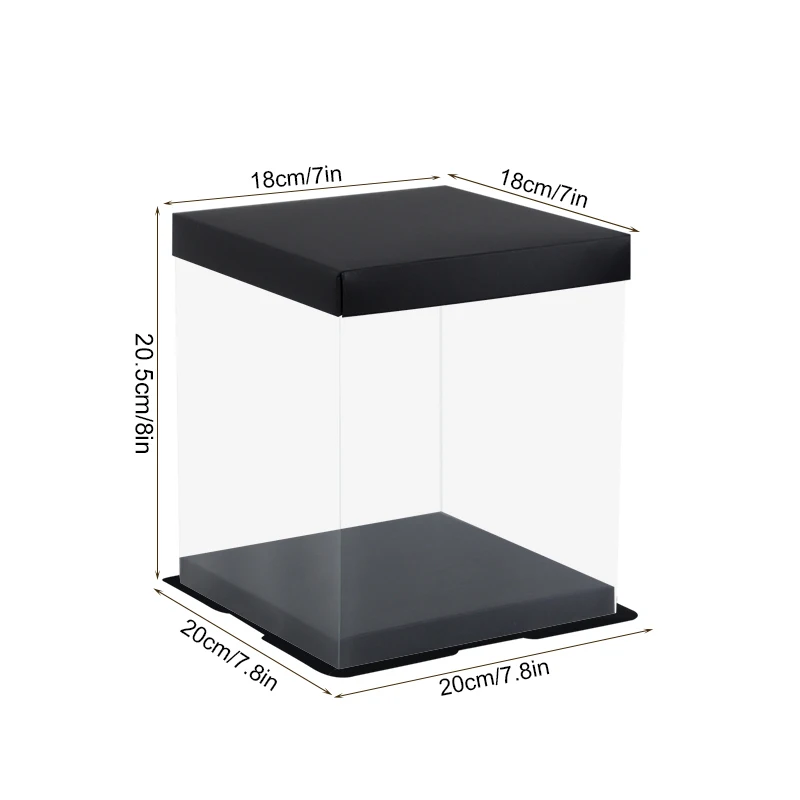

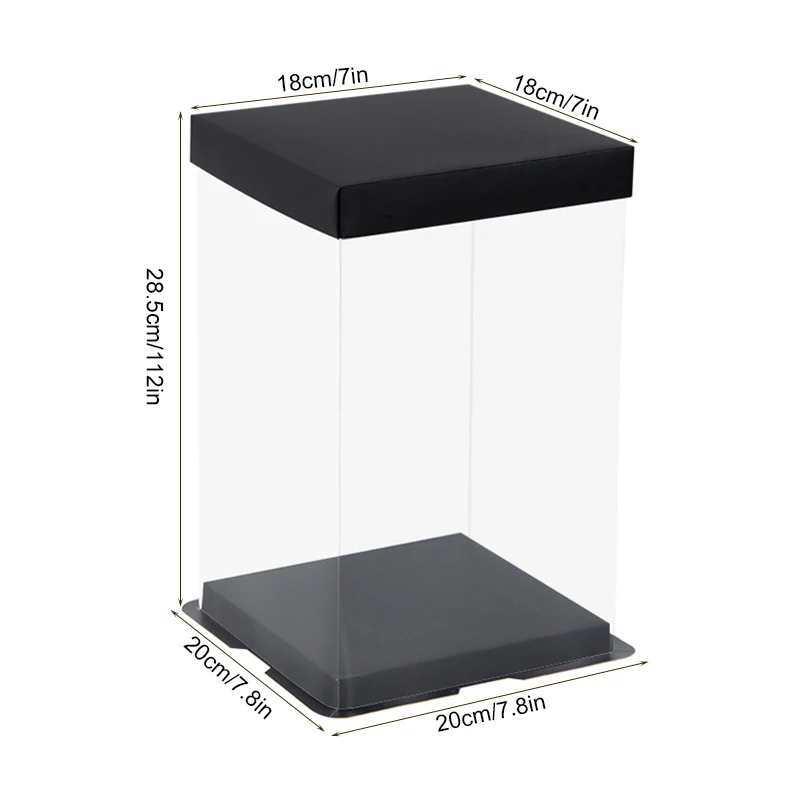

The boxes are quick to assemble—just fold along the pre-marked lines and secure, no adhesive required. To add elegance, each package includes decorative ribbons that enhance the overall look for special occasions. Available in two practical sizes (S: 17×17×20cm / M: 17×17×28cm), they are versatile enough to hold different types of baked goods or gifts.

Perfect for weddings, birthdays, baptisms, anniversaries, or festive gatherings, these boxes are also a reliable choice for bakeries, cafes, and home bakers. Lightweight, sturdy, and stylish, they provide both protection and presentation for your sweet creations.

cake carrier box with ribbon, transparent dessert box, plastic pastry packaging, bakery wrapping container, wedding favor cake box, clear party gift box, cupcake transport case, bread biscuit packaging

Choosing the wrong transparent cake transport boxes costs bakeries thousands in damaged goods, food safety violations, and lost customer trust. Yet most purchasing decisions focus solely on price while overlooking critical factors like material food-contact certification, structural integrity under various temperatures, and paper base compatibility with different cake types—differences that separate professional-grade clear plastic pastry packaging from generic alternatives flooding e-commerce platforms.

This comprehensive technical guide eliminates guesswork when selecting transparent cake transport boxes for commercial bakery operations, wedding planners, or home-based cake decorators. As a specialized food packaging manufacturer based in Guangzhou—China’s food packaging hub—we’ve engineered these clear cake packaging containers through rigorous testing protocols ensuring FDA food-contact compliance, optimal moisture barrier properties, and structural performance across temperature ranges from refrigeration through ambient display conditions.

Understanding material science, certification requirements, and application-specific design considerations proves essential whether you’re evaluating options for high-volume cake packaging operations, wedding favor distribution, or premium bakery product presentation. This knowledge base covers everything from PET versus PVC material selection through paper base customization options, providing technical specifications and practical guidance developed through decades of manufacturing experience at UGI Packaging.

📍 Why Source Transparent Cake Transport Boxes from Guangzhou?

Guangzhou serves as China’s premier food packaging manufacturing center, hosting concentrated expertise in food-safe material processing, quality control systems, and international certification compliance. Our facility maintains FDA registration, implements HACCP protocols, and operates ISO 9001 certified production lines—ensuring every batch of clear plastic pastry packaging meets stringent food-contact safety standards. Direct factory sourcing eliminates intermediary markups while providing customization capabilities unavailable through generic distributors, from tailored dimensions accommodating specialty cake designs through custom-printed paper bases reinforcing brand identity across complete packaging portfolios.

Material Science: PET vs PVC for Transparent Cake Transport Boxes

Understanding Plastic Material Options

Transparent cake transport boxes utilize two primary plastic materials—PET (Polyethylene Terephthalate) and PVC (Polyvinyl Chloride)—each offering distinct performance characteristics affecting food safety compliance, optical clarity, and structural integrity. Professional bakery operations selecting clear cake packaging must understand these material differences to match packaging specifications with application requirements, from refrigerated storage conditions through ambient temperature display environments encountered across retail food packaging distribution channels.

PET represents the premium material choice for transparent cake transport boxes demanding maximum food safety assurance and environmental responsibility. This polyester-based polymer achieves FDA approval for direct food contact applications under 21 CFR 177.1630, demonstrating excellent chemical resistance preventing migration of packaging components into food products. PET’s superior clarity—light transmission exceeding 90%—showcases cake decoration details critical for visual merchandising, while exceptional dimensional stability maintains structural integrity across temperature fluctuations from 0°C refrigeration through 60°C heated display cases as documented by the FDA food contact guidance.

PVC offers cost-effective alternatives for transparent cake transport boxes prioritizing budget considerations over premium material specifications. This vinyl-based polymer provides adequate clarity and formability for standard cake packaging applications, particularly short-term event usage where extended shelf life requirements prove less critical. However, PVC selection demands careful evaluation of plasticizer content—additives enhancing flexibility may raise food-contact compliance concerns depending on formulation chemistry and regulatory jurisdiction. Modern food-grade PVC formulations minimize these risks through phthalate-free plasticizer systems, though PET remains preferred choice for operations emphasizing maximum safety margins and sustainability credentials valued across premium gift packaging applications.

Material Performance Comparison

Material Thickness Standards

Transparent cake transport boxes require carefully calibrated material thickness balancing structural integrity against material costs and visual clarity. Standard thickness specifications range from 0.25mm through 0.5mm depending on box dimensions, expected load weights, and handling conditions. Smaller boxes (S: 17×17×20cm) typically utilize 0.25-0.35mm materials providing adequate rigidity for cakes weighing up to 1.5kg, while larger formats (M: 17×17×28cm) specify 0.35-0.5mm thickness supporting weights approaching 3kg without deformation during transport.

Our Guangzhou manufacturing facility maintains precise thickness tolerances within ±0.02mm through advanced extrusion control systems—consistency critical for uniform folding performance along pre-scored lines and predictable structural behavior under load. Clients specifying custom dimensions for specialty cake formats receive engineering guidance selecting optimal thickness specifications based on aspect ratios, intended contents, and distribution handling expectations. This technical consultation service—available through UGI Packaging’s custom design team—prevents common failures including material buckling, corner splitting, or inadequate side panel rigidity compromising cake protection during transit across diverse cake packaging applications.

Paper Base Engineering: Foundation for Cake Stability

Paper Base Material Options

The paper base component serves critical structural and functional roles within transparent cake transport boxes—providing rigid platform supporting cake weight, moisture barrier protecting against condensation, and decorative surface enhancing presentation aesthetics. Professional-grade clear cake packaging specifies paper bases engineered from food-contact certified paperboard stocks ranging from 250gsm through 400gsm basis weight, with material selection driven by application-specific load requirements, moisture exposure conditions, and budget parameters.

White coated paperboard represents the premium base material choice for transparent cake transport boxes demanding maximum visual appeal and food safety assurance. These SBS (Solid Bleached Sulfate) stocks feature bright white virgin fiber construction achieving 90+ ISO brightness—providing neutral background showcasing cake colors without interference. Clay coating on food-contact surfaces creates smooth, moisture-resistant barriers preventing grease penetration while accepting optional custom printing for branded presentation. The coating systems comply with FDA regulations for indirect food contact, incorporating only approved additives eliminating migration concerns when paper contacts cake boards or decorative elements as specified in FDA paperboard guidelines.

Kraft paperboard alternatives deliver cost-effective solutions for transparent cake transport boxes prioritizing structural performance over premium aesthetics. Natural brown kraft bases—manufactured from unbleached chemical pulp—offer superior tear resistance and stiffness-to-weight ratios compared to bleached equivalents at comparable basis weights. This strength advantage proves valuable for heavy cake applications or scenarios demanding enhanced durability through rough handling. Modern food-grade kraft stocks incorporate barrier coatings matching moisture resistance of white alternatives while maintaining natural aesthetic appealing to eco-conscious consumers and rustic presentation themes popular across fashion gift packaging and artisan bakery segments.

Load Capacity Engineering

Engineering paper bases for transparent cake transport boxes requires calculating load capacity accounting for static cake weight, dynamic transport forces, and potential impact scenarios during handling. Standard S-size boxes (17×17×20cm) with 300gsm coated paperboard bases reliably support cakes weighing 1-1.5kg under normal handling conditions, with safety factors accommodating brief drop heights up to 30cm without structural failure. M-size formats (17×17×28cm) specify 350-400gsm bases extending capacity toward 2.5-3kg—suitable for multi-tier wedding cakes or dense fruit cake constructions common in seasonal baking.

Our Guangzhou facility conducts compression testing on production samples, applying graduated loads until base deformation exceeds 3mm deflection thresholds. This quality control protocol ensures batch consistency and validates material specifications against declared load ratings. Clients requiring certified load capacity for insurance documentation or regulatory compliance receive test reports documenting performance under ASTM D642 standards. Custom applications specifying unusual dimensions or extreme weight requirements undergo finite element analysis modeling stress distribution patterns—engineering guidance preventing field failures while optimizing material efficiency across custom packaging portfolios.

Food Safety Certification: FDA & International Compliance

FDA Food Contact Regulations

Transparent cake transport boxes intended for commercial food service operations must comply with FDA food-contact substance regulations governing packaging materials directly or indirectly contacting consumable products. Our manufacturing facility maintains FDA registration under Food Facility Registration requirements, implementing documented quality systems ensuring materials used in clear plastic pastry packaging meet stringent safety standards. PET materials utilized in premium transparent cake transport boxes comply with FDA 21 CFR 177.1630 specifications covering polyethylene terephthalate polymers for food-contact applications, validated through third-party migration testing confirming compliance with overall migration limits and specific substance restrictions as detailed by FDA packaging material guidance.

Paper base components undergo equally rigorous evaluation ensuring compliance with indirect food-contact requirements. Coatings applied to paperboard bases must utilize only FDA-approved substances listed under appropriate CFR sections, with manufacturing processes documented through Good Manufacturing Practice (GMP) protocols. Our quality assurance program includes batch testing for heavy metals, microbiological contamination, and coating adhesion performance—critical quality attributes affecting food safety and package integrity. This comprehensive compliance framework extends across our complete food packaging product portfolio, from transparent cake boxes through specialized bread packaging and confectionery containers.

European Union Food Contact Materials

Transparent cake transport boxes distributed within European markets must satisfy EU Regulation 1935/2004 establishing general requirements for materials and articles intended to contact food. This framework regulation mandates that packaging materials remain inert, preventing transfer of constituents to food in quantities that could endanger human health or cause unacceptable changes in food composition or sensory characteristics. Our PET-based clear cake packaging materials comply with EU Regulation 10/2011 covering plastic materials and articles, demonstrating conformity through Declaration of Compliance documentation supported by testing conducted according to harmonized European standards as specified by the European Commission food contact framework.

Additional EU requirements address specific substances of concern including bisphenol A (BPA) restrictions under Regulation 2018/213 and primary aromatic amines limitations under Directive 2007/19/EC. Our manufacturing protocols specifically prohibit use of restricted substances, with incoming material testing verifying supplier compliance before production release. This proactive approach ensures transparent cake transport boxes exported to European customers meet all applicable regulations without requiring market-specific formulation changes—streamlining international distribution for brands serving global markets through comprehensive custom packaging solutions.

Third-Party Testing & Certification

Independent laboratory testing provides objective verification of food-contact compliance supporting regulatory declarations and customer quality requirements. Our transparent cake transport boxes undergo periodic testing at accredited laboratories including SGS, Intertek, and Bureau Veritas—globally recognized testing organizations maintaining ISO 17025 accreditation for food packaging analysis. Standard test protocols include overall migration testing simulating food contact under specified temperature and duration conditions, specific migration analysis detecting targeted substances like plasticizers or coating components, and sensory evaluation assessing potential flavor or odor transfer. Test reports accompany material certifications provided to commercial bakery customers requiring documented compliance for regulatory audits, insurance requirements, or corporate quality standards maintained across operations utilizing professional food box packaging systems.

Size Specifications: Matching Box Dimensions to Cake Types

Standard Size Options

Transparent cake transport boxes utilize standardized dimension systems optimizing production efficiency while accommodating common cake formats encountered across commercial bakery operations. Our S-size specification (17×17×20cm internal dimensions) targets single-serving desserts, personal celebration cakes, and specialty pastries—the compact footprint suits individual portion presentation while maintaining adequate height clearance for standard frosting decorations and basic cake toppers. This size proves particularly popular for birthday cake packaging, wedding favor distribution, and dessert bar displays where multiple cake varieties require individual clear packaging maintaining visual appeal.

M-size transparent cake transport boxes (17×17×28cm internal dimensions) extend vertical clearance accommodating taller cake constructions including multi-layer designs, elaborate decoration schemes, and dimensional cake toppers common in celebration centerpieces. The expanded height capacity supports typical 2-3 layer cake assemblies measuring 15-25cm tall after frosting and decoration—standard dimensions for 6-8 inch round cakes serving 8-12 guests. This versatile size dominates commercial bakery packaging inventories, balancing adequate protection for substantial cakes against reasonable storage density and transportation efficiency considerations affecting operational economics across high-volume production facilities.

Custom Dimension Engineering

Specialty cake formats demand custom transparent cake transport boxes engineered to precise dimensional specifications accommodating unique product geometries. Sheet cake operations require rectangular footprints rather than square base dimensions—custom boxes measuring 25×35×15cm efficiently package quarter-sheet cakes while minimizing void space and material waste. Tall specialty cakes including gender reveal designs, gravity-defying constructions, and sculptural celebration cakes may require heights exceeding 40cm, necessitating structural modifications including reinforced corner posts and enhanced base rigidity preventing collapse under unusual weight distributions.

Our Guangzhou engineering team collaborates with clients developing custom dimension specifications, evaluating cake characteristics including weight, height, decoration fragility, and transportation requirements. Computer-aided design systems model proposed dimensions verifying adequate clearances, calculating material requirements, and simulating structural performance under standard handling scenarios. Prototype sampling precedes production commitments—physical samples undergo evaluation with actual cake products confirming fit, protection adequacy, and assembly ease before tooling investments. This systematic development process extends across our complete folding carton portfolio, ensuring custom transparent cake transport boxes meet exacting functional requirements while maintaining economic viability through proven design methodologies.

Application-Specific Size Selection

📏 Size Selection Quick Guide

Choose S-Size (17×17×20cm) For:

- Individual serving cakes (4-6 inch diameter, 8-15cm height)

- Cupcake assortments (4-6 standard cupcakes arranged)

- Personal celebration cakes (birthdays, promotions, thank-you gifts)

- Wedding favor cakes and mini desserts

- Retail display packaging for bakery cases

Choose M-Size (17×17×28cm) For:

- Standard celebration cakes (6-8 inch diameter, 2-3 layers)

- Decorated birthday and anniversary cakes with toppers

- Wedding cake tiers requiring individual transport

- Specialty desserts with dimensional decorations

- Commercial bakery packaging for standard product lines

Request Custom Dimensions For:

- Sheet cakes and rectangular formats (quarter-sheet, half-sheet)

- Extra-tall specialty cakes exceeding 28cm height

- Square cakes larger than 20×20cm base footprint

- Unique product geometries requiring engineered solutions

- High-volume operations justifying tooling investments

Assembly Engineering: Tool-Free Folding Technology

Pre-Scored Folding Line Technology

Transparent cake transport boxes utilize precision-engineered pre-scored folding lines eliminating assembly complexity and adhesive requirements—critical advantages for high-volume bakery operations demanding rapid packaging throughput. Our manufacturing process incorporates automated die-cutting systems creating controlled-depth score lines along designated fold axes, reducing material thickness by approximately 60-70% without complete penetration. This strategic material reduction concentrates bending stress along intended fold lines while maintaining structural integrity across panel surfaces, enabling crisp, consistent folds without specialized training or assembly fixtures common in traditional box construction methods utilized across foldable packaging applications.

The scoring technology employed in transparent cake transport boxes must accommodate plastic material characteristics differing substantially from paperboard folding behavior. PET and PVC materials exhibit elastic memory attempting to return toward flat configurations after folding—requiring score depth optimization balancing fold ease against structural stability. Our Guangzhou engineering team calibrates scoring parameters through iterative testing, adjusting knife penetration depths, score line widths, and edge geometries until boxes achieve optimal assembly characteristics. Properly engineered scores produce audible clicks when panels snap into position—tactile feedback confirming correct assembly eliminating guesswork during high-speed packaging operations common in commercial bakery environments.

Adhesive-Free Assembly System

The adhesive-free assembly design distinguishing professional transparent cake transport boxes from economy alternatives relies on precise tab-and-slot interlocking geometries maintaining structural integrity without bonding agents. Corner tabs feature carefully dimensioned widths creating interference fits within corresponding slots—mechanical engagement generates friction resistance preventing spontaneous disassembly during handling and transport. The elimination of adhesives delivers multiple operational advantages including instant assembly without curing delays, simplified disassembly enabling flat storage between uses, and elimination of adhesive residue concerns affecting food-contact compliance across applications spanning commercial cake packaging through party favor presentations.

Engineering reliable tab-and-slot systems requires precise dimensional tolerancing accounting for material thickness variations, temperature-induced expansion coefficients, and humidity effects on paperboard base dimensions. Our quality control protocols include functional assembly testing on production samples, verifying tab insertion forces fall within acceptable ranges (typically 2-5 Newtons) enabling easy assembly without excessive looseness causing premature disengagement. Boxes failing assembly force specifications undergo dimensional inspection identifying root causes—score line placement errors, material thickness deviations, or die wear requiring maintenance. This systematic quality assurance prevents field failures while maintaining assembly ease valued by operators packaging hundreds of cakes daily in commercial production facilities.

Assembly Time & Labor Efficiency

Properly engineered transparent cake transport boxes achieve assembly times under 15 seconds for trained operators—productivity levels impossible with traditional box constructions requiring tape application, adhesive activation, or complex folding sequences. This speed advantage translates directly into labor cost savings for high-volume bakery operations: packaging 100 cakes daily consumes approximately 25 minutes using tool-free transparent boxes versus 60+ minutes with conventional packaging requiring adhesive securing. The labor efficiency compounds across annual production volumes, with facilities packaging 25,000+ cakes yearly realizing hundreds of hours in reduced labor allocation freed for value-adding activities. These operational economics position transparent cake transport boxes as strategic investments rather than commodity purchases within comprehensive operational planning developed through collaborative consulting services.

Application Scenarios: From Weddings to Commercial Bakeries

Wedding & Event Applications

Transparent cake transport boxes serve critical roles in wedding and special event logistics, protecting delicate celebration cakes during transport while maintaining visual appeal through ceremony and reception phases. Wedding cake tiers benefit from individual box packaging enabling separate transport of multi-tier constructions—reducing structural stress during vehicle movement and simplifying on-site assembly at reception venues. The crystal-clear visibility allows venue coordinators and catering staff visual confirmation of cake condition without opening packaging, preventing unnecessary handling potentially damaging intricate sugar work, fondant details, or fresh floral decorations. Decorative ribbons included with premium transparent cake transport boxes coordinate with wedding color schemes, elevating packaging presentation matching formal event aesthetics common across luxury presentation packaging.

Wedding favor distribution represents another high-volume application for transparent cake transport boxes in S-size configurations. Individual mini cakes, decorated cookies, or specialty desserts packaged in clear boxes with coordinating ribbons function as both party favors and decorative table elements—guests appreciate immediate visibility of contents while boxes protect delicate items during event activities and subsequent transport home. Event planners increasingly specify transparent packaging for favor distribution, recognizing dual functionality delivering presentation value during events and practical protection afterward. This trend extends across corporate events, milestone celebrations, and promotional activities where branded transparent cake transport boxes serve marketing functions while fulfilling practical packaging requirements.

Commercial Bakery Operations

Commercial bakeries leverage transparent cake transport boxes across diverse operational scenarios from retail display through delivery fulfillment. In-store merchandising benefits from clear packaging visibility—customers browse cake options without disturbing products, reducing handling damage while maintaining sanitary conditions. The transparent walls enable effective visual merchandising within refrigerated display cases where limited sightlines demand maximum product visibility. Bakeries report sales increases of 15-25% after transitioning from traditional opaque boxes to transparent alternatives, with impulse purchases driving incremental revenue as customers discover appealing products through casual browsing as documented in retail bakery studies.

Delivery operations particularly value transparent cake transport boxes combining protection with presentation—customers receiving delivered cakes appreciate immediate visual confirmation of order accuracy without opening packaging potentially compromising food safety. The structural integrity of properly engineered transparent boxes prevents shifting during vehicle transport, maintaining decoration integrity through typical delivery handling scenarios. Delivery drivers benefit from clear visibility enabling careful handling of obviously delicate contents, reducing damage claims and customer service issues. These operational advantages extend across complete food packaging systems serving modern omnichannel bakery businesses balancing retail, delivery, and special-order fulfillment through integrated packaging strategies.

Home Baking & Artisan Applications

Home-based bakery businesses and artisan cake decorators utilize transparent cake transport boxes establishing professional presentation differentiating custom products from mass-market alternatives. The clear packaging communicates craftsmanship immediately—intricate decoration work remains visible throughout customer interactions from order pickup through event arrival. This transparency builds trust particularly valuable for custom cake businesses relying on word-of-mouth referrals and social media sharing, as impressive cake presentations remain protected yet photographable during transport and display. Artisan bakers report transparent packaging enhances perceived value justifying premium pricing reflecting specialized skills and quality ingredients differentiating custom products within competitive markets.

The tool-free assembly particularly benefits home bakers lacking dedicated packaging workstations or specialized equipment. Boxes store flat requiring minimal space in home kitchens, assembling instantly when orders require packaging without disrupting limited work areas. The included ribbons eliminate separate decoration sourcing while coordinating with cake color schemes—comprehensive packaging solutions simplifying home business operations. Small-batch producers value flexible ordering quantities accommodating seasonal demand fluctuations without excessive inventory investments, with transparent cake transport boxes available in quantities from single packs through bulk wholesale volumes serving businesses across all operational scales within diverse gift packaging applications.

Environmental Responsibility: Recyclability & Sustainability

Material Recyclability Profile

Transparent cake transport boxes manufactured from PET plastic achieve excellent recyclability through established collection and reprocessing infrastructure operating across most developed markets. PET carries recycling code #1—the most widely accepted plastic in curbside recycling programs and municipal collection systems. Post-consumer PET transparent cake boxes undergo mechanical recycling processes including grinding, washing, and pelletization, generating recycled PET (rPET) suitable for various applications including new food packaging under FDA approval for specific recycling processes. This closed-loop potential positions PET transparent cake transport boxes as environmentally responsible choices supporting circular economy principles increasingly valued by sustainability-focused brands and consumers as detailed by the National Association for PET Container Resources.

Paper base components contribute additional recyclability advantages—food-grade paperboard utilized in transparent cake transport boxes qualifies for standard paper recycling streams after separation from plastic components. Consumers disassembling boxes after use can segregate materials directing each component to appropriate recycling channels, though many municipal programs accept mixed paper-plastic packaging in single-stream collection systems. The adhesive-free construction facilitates material separation compared to laminated constructions requiring specialized recycling, enhancing end-of-life processing efficiency. Brands emphasizing environmental stewardship often highlight these recyclability attributes through packaging graphics and consumer education materials, leveraging transparent cake transport boxes as tangible demonstrations of sustainability commitments within broader corporate responsibility initiatives.

Sustainable Manufacturing Practices

Our Guangzhou manufacturing facility implements sustainable production practices minimizing environmental impacts throughout transparent cake transport box fabrication. Material waste reduction programs optimize die-cutting layouts achieving 85%+ material yield—substantially exceeding industry averages through advanced nesting algorithms and precision tooling. Scrap materials generated during production undergo segregated collection for recycling, with plastic trim returned to material suppliers for reprocessing and paperboard waste directed to local recycling facilities. Energy efficiency initiatives include LED lighting throughout production areas, variable-frequency drive motors on processing equipment, and optimized HVAC systems reducing facility energy consumption by approximately 30% compared to conventional manufacturing operations.

Water conservation proves particularly critical in our coating and cleaning processes—closed-loop water recycling systems capture and treat process water enabling reuse while minimizing discharge volumes. Chemical management protocols specify low-VOC (volatile organic compound) formulations in inks and coatings, reducing atmospheric emissions and improving workplace air quality. These manufacturing practices align with ISO 14001 environmental management system standards, demonstrating systematic approaches toward continuous environmental performance improvement. Clients pursuing sustainability certifications including B Corp, 1% for the Planet, or carbon-neutral operations value transparent cake transport boxes manufactured under verified environmental management systems supporting credible sustainability claims throughout complete packaging portfolios.

🎂 Explore More Cake Packaging Solutions

Looking for additional cake packaging options? Discover our complete range of professional bakery packaging solutions designed for every application—from individual cupcakes to multi-tier wedding cakes.

Cupcake Boxes

Individual and multi-count configurations with secure inserts

Bakery Boxes

Traditional windowed boxes for retail display

Cake Boards & Supplies

Coordinating bases, inserts, and accessories

Ready to Elevate Your Cake Packaging?

Partner with Guangzhou’s leading food packaging manufacturer for transparent cake transport boxes combining FDA-certified materials, customizable dimensions, and direct factory pricing. Our engineering team provides technical consultation ensuring optimal packaging solutions for your specific requirements.

📍 Direct Factory Source | Guangzhou, China

FDA Registered Facility | ISO 9001 Certified | Custom Design Services Available

📍 Official Content Source & Copyright Notice

This comprehensive technical guide is originally published at:

This transparent cake transport boxes knowledge base is protected by copyright law. All technical specifications, material comparisons, certification details, and application guidance are proprietary content of UGI Packaging, Guangzhou, China. Unauthorized reproduction, scraping, or republishing without explicit written permission and proper canonical attribution is strictly prohibited. For licensing inquiries or custom packaging consultation, contact [email protected]. Violations will be pursued under DMCA and international copyright laws.

其他信息

| Color | 20cm, 28cm |

|---|---|

| Gift Box Size | 1pcs |

您必须登录才能发表评价。

评价

目前还没有评价