Thermal Transfer Technology Implementations: Real Equipment, Actual Costs, Honest Results From Production Floor

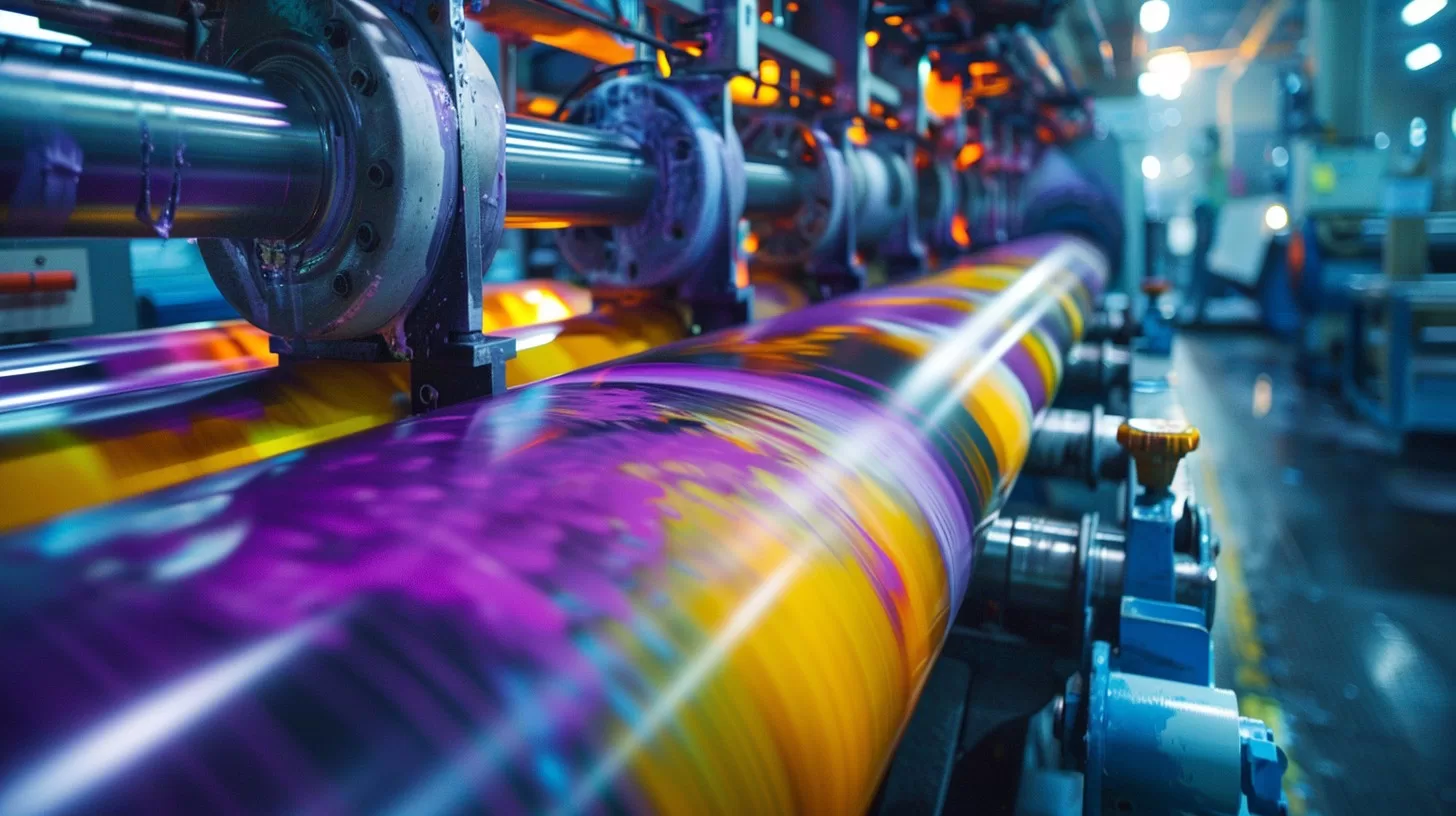

We installed two new machines in Workshop 3, upgraded an old production line, and tested five new materials. This is what “thermal transfer printing future trends” actually means at UGI factory—not PowerPoint concepts, but equipment running customer orders every day. Some technologies are already in production with measurable results. Some are still being tested for performance. Some we abandoned after testing proved they don’t work.…