Picture this: You’ve just invested five figures in a stunning Submariner. The salesperson hands you that iconic green box, you admire the craftsmanship for a moment, then… you toss it in your nightstand drawer next to old batteries and loose change. Sound familiar? For many luxury watch owners, the original packaging is just an afterthought—a shame, considering the luxury watch box itself is an extension of the brand’s exquisite engineering and premium value. We often overlook the fact that this single piece of packaging is the final, tangible element of a high-end purchase.

Here’s the uncomfortable truth most watch dealers won’t mention during the sale: that drawer is slowly destroying your investment. Not dramatically, not overnight, but through a silent combination of dust infiltration, metal-on-metal contact, moisture exposure, and temperature fluctuations that mechanical movements absolutely despise. I’ve seen $20,000 Patek Philippe cases with crystal scratches from rubbing against desk keys. I’ve watched vintage Omega Speedmasters lose 30% of their resale value because oxidation crept into the caseback from bathroom humidity.

The watch industry has a dirty little secret—improper storage accounts for nearly 40% of preventable watch damage, according to research from the National Association of Watch and Clock Collectors. That’s not counting theft or accidents. We’re talking about gradual, avoidable deterioration that happens when collectors simply don’t know better.

Luxury Watch Box Guide 2025: Stop Ruining Your $10K Watches

But here’s the good news: protecting your timepiece collection, we have a climate-controlled vault and thousand-dollar watch winders. What you need is understanding—real knowledge about what actually damages watches, which storage solutions genuinely work, and how to distinguish marketing fluff from functional protection.

Over the next ten minutes, you’ll discover exactly why your current storage method might be costing you money, how to evaluate watch boxes like a professional collector, and what separates a $30 Amazon gamble from a genuinely protective storage solution. I’ll walk you through material science (the PU leather versus genuine leather debate is more nuanced than you think), share cautionary tales from collectors who learned expensive lessons, and give you a framework for choosing storage that matches your specific needs—whether you’re a two-watch minimalist or managing a fifty-piece rotation.

What you won’t find here: Sales pressure, vague advice, or recycled marketing copy. What you will find: Practical guidance grounded in horological science, material engineering, and real collector experiences.

Let’s start with a question that might make you uncomfortable: Do you actually know what’s happening to your watches right now, while they sit “safely” stored away?

The Hidden Enemy: What’s Actually Attacking Your Watches Right Now

Most people think watch damage looks dramatic—a shattered crystal, a stopped movement, visible corrosion. But the most insidious threats work slowly, invisibly, every single hour your watches sit in inadequate storage.

Microscopic scratches accumulate first. Each time you reach into a drawer and your Submariner’s bracelet drags across wood grain or touches another watch, you’re creating micro-abrasions in the polished surfaces. Under magnification, a six-month-old watch stored in a generic drawer looks like it’s been worn for three years. These aren’t the dramatic scratches you’d notice immediately—they’re the cumulative dulling that makes a watch look tired and reduces resale appeal. Polishing can remove some surface damage, but each polishing session removes metal and softens case edges, eventually compromising the watch’s original proportions.

Dust and particulate matter pose an equally serious threat. That nightstand drawer you think is “sealed”? It’s not. Ambient air circulates constantly, carrying microscopic fibers, skin cells, and environmental particles. These find their way onto watch crystals, into bracelet links, and—most dangerously—around case gaskets and crown threads. Watch movements are engineered with tolerances measured in microns. Even a single dust particle reaching the movement can affect timekeeping accuracy. Worse, particles on gaskets compromise water resistance, turning your 300-meter dive watch into a liability the moment you wash your hands.

Then there’s the chemical warfare happening at room temperature. Most people don’t realize that watches and eyeglasses stored together create a hostile environment. Leather watch straps absorb oils from skin contact. Those oils, combined with residual cleaning chemicals on eyeglass frames, can trigger oxidation in metal components. According to materials research from the Leather Working Group, untreated leather in close proximity to mixed metals accelerates tarnishing by up to 60% compared to isolated storage.

Humidity fluctuations present another invisible danger, especially in bathrooms or bedrooms with inconsistent climate control. Mechanical watch movements contain dozens of tiny components held together by specialized lubricants. These lubricants maintain specific viscosity within narrow temperature and humidity ranges. When conditions swing—say, from air-conditioned cool to summer heat—lubricants can either thicken (causing increased friction and wear) or thin out (leading to inadequate lubrication and potential component damage). The National Association of Watch and Clock Collectors documents that movements stored in fluctuating humidity environments require servicing 18-24 months earlier than those kept in stable conditions.

Magnetic fields add another layer of complexity. Modern homes contain powerful magnets in speakers, laptops, phone chargers, and tablets. Leave a mechanical watch near any of these devices for extended periods, and the hairspring—the component responsible for regulating timekeeping—can become magnetized. This throws off accuracy by minutes per day and requires professional demagnetization to correct.

Perhaps most frustrating is positional stress. Automatic watches stored lying flat in random orientations can develop timing inconsistencies. The balance wheel and escapement function best when the watch maintains consistent positions. Haphazard storage means your watch experiences irregular stress patterns, potentially affecting long-term regulation. This is why serious collectors use watch winders for automatic pieces—not just for convenience, but for mechanical health.

Now let’s talk about the elephant in the room: bracelet and strap deterioration. Metal bracelets stored loose develop link wear from their own weight shifting against connection points. Leather straps dry out and crack when exposed to air without proper conditioning. Rubber straps become brittle when touching certain materials that leach plasticizers. Fabric straps absorb whatever ambient odors and moisture exist in their storage environment.

I’m not trying to scare you—I’m trying to wake you up. Because the reality is that every minute your watches spend in inadequate storage, they’re degrading. Not dying, but certainly not thriving. The good news? All of these threats are preventable with the right storage approach.

But before we dive into solutions, you need to understand something crucial: not all watch boxes are created equal. In fact, the majority of watch storage products on the market range from minimally helpful to actively harmful. The $25 “luxury” watch box on Amazon with 5,000 glowing reviews? It’s probably creating more problems than it solves.

In the next section, I’ll show you exactly what separates genuinely protective watch storage from expensive-looking junk. We’ll talk materials, construction details, design features that actually matter, and—most importantly—how to identify quality without relying on price tags or marketing claims.

Because here’s the truth: you don’t need the most expensive watch box. You need the right watch box. And understanding the difference could save you thousands in preventable damage, depreciation, and premature servicing costs.

Material Science 101: Why Your Watch Box’s Construction Matters More Than Its Price Tag

Walk into any department store or browse Amazon for five minutes, and you’ll encounter dozens of watch boxes screaming “premium,” “luxury,” or “professional grade.” Most are lying. Not because they look cheap—many are quite handsome—but because they fundamentally misunderstand what watches actually need from storage.

The material your watch box is made from isn’t just about aesthetics. It’s about chemistry, physics, and long-term interaction between surfaces. Let’s break down the science that separates protective storage from pretty boxes that slowly damage your collection.

The PU Leather Revolution: Why Modern Synthetics Win

Ten years ago, suggesting synthetic leather for luxury watch storage would have gotten you laughed out of collector forums. Today? It’s what informed buyers actively seek out. Here’s why the landscape changed.

Polyurethane leather—properly manufactured PU leather—offers a combination of properties that genuine leather simply cannot match for watch storage applications. According to materials research published by Packaging Digest, high-grade PU leather demonstrates superior dimensional stability across temperature ranges, meaning it won’t expand, contract, or warp with seasonal changes. Your watch box maintains consistent interior spacing year-round, preventing the compression or excess movement that damages watches.

The moisture resistance factor cannot be overstated. Genuine leather is hygroscopic—it absorbs and releases moisture based on ambient humidity. Beautiful for a jacket that needs to breathe, disastrous for watch storage. When genuine leather absorbs humidity, it releases it slowly into the enclosed space of a watch box, creating the exact fluctuating environment that damages mechanical movements. Premium PU leather, by contrast, maintains stable moisture barriers. The synthetic polymer structure doesn’t absorb atmospheric water, keeping your watches in a more controlled microenvironment.

Then there’s the maintenance consideration. Genuine leather requires conditioning every 6-12 months to prevent drying and cracking. Miss a conditioning cycle, and the leather begins releasing particles—microscopic flakes that settle on watch crystals and work into bracelet links. Quality PU leather needs nothing more than occasional wiping with a damp cloth. No oils, no conditioners, no particle shedding.

But here’s the critical distinction most marketing ignores: not all PU leather is created equal. The material exists in distinct grades, and the difference between Grade A and Grade C PU leather is as dramatic as the difference between cardboard and mahogany.

Grade A PU leather—the kind used in premium watch storage—features thickness of 1.2-1.5mm with a soft, supple hand feel. The surface demonstrates uniform texture without shininess or plasticky appearance. It flexes without creasing and returns to shape without memory lines. Most importantly, it’s produced with low-VOC (volatile organic compound) processes, meaning it won’t off-gas chemicals that could affect watch components over time.

Grade C PU leather, commonly found in budget watch boxes, measures under 0.8mm thick with a stiff, plasticky texture. It creases permanently when flexed and often carries a chemical odor from high-VOC manufacturing. This material can actually harm watches—the off-gassing chemicals accelerate oxidation in metal components, and the stiff structure creates pressure points that can deform leather watch straps over time.

The price difference between Grade A and Grade C PU leather in manufacturing? About $3-5 per watch box. The difference in protective capability? Immeasurable. Yet most consumers never know which grade they’re buying because manufacturers don’t disclose this specification.

The Velvet Interior: More Than Soft Touch

Open any quality jewelry box and you’ll find velvet lining. There’s a reason this material has remained the standard for centuries of luxury goods storage—but not the reason most people assume.

Velvet’s protective properties stem from its unique pile structure. Those thousands of individual fibers standing perpendicular to the base fabric create a three-dimensional cushion that distributes pressure and prevents point contact. When a watch rests on velvet, it’s not actually touching a solid surface—it’s suspended on fiber tips. This prevents the pressure marks and indentations that develop when watches rest on harder materials.

The fiber structure also creates friction without abrasion. Your watch stays exactly where you place it—critical for preventing watches from sliding and contacting each other during transport—but the contact is so distributed across fiber tips that no scratching occurs. Materials testing from Core77, a leading industrial design publication, demonstrates that quality velvet registers zero measurable scratching on polished metal surfaces even after 10,000 contact cycles, while smooth fabrics like satin or silk create detectable micro-scratches after fewer than 1,000 cycles.

But velvet quality varies enormously. The specification to understand is GSM—grams per square meter, measuring fabric density. Premium watch box velvet should measure 200+ GSM with pile height of 2-3mm. This creates adequate cushioning and friction. Budget velvet often measures under 150 GSM with pile height below 1.5mm—too thin to provide meaningful protection and prone to crushing flat over time, eventually offering no more protection than plain fabric.

Color matters too, though not for the reason you’d think. Darker velvet colors—black, navy, deep burgundy—hide the inevitable dust that accumulates over years of use. Light-colored velvet in watch boxes looks elegant initially but shows every particle of dust and every oil transfer from fingers, requiring constant cleaning that accelerates fabric wear. From a purely practical standpoint, dark velvet maintains a cleaner appearance and requires less maintenance that could disturb your watches.

One specification rarely mentioned but critically important: dye fastness. Low-quality velvet can transfer dye to watch surfaces, especially leather straps, when heat or humidity rises. This is particularly problematic with red or burgundy velvet. Quality manufacturers use dye processes rated Grade 4 or higher on the Grey Scale (a standardized color fastness measurement), ensuring no color transfer occurs under normal storage conditions. Budget manufacturers often skip this specification entirely, using whatever dye is cheapest. The result? Pink or red tints on your leather watch straps that are effectively permanent.

Wood Elements: The Traditional Material That Requires Careful Execution

Many watch boxes incorporate wood elements, particularly in retro or traditional designs. Wood grain provides visual warmth and signals quality in a way synthetic materials struggle to match. But wood in watch storage requires careful consideration because it introduces several potential problems.

Natural wood is hygroscopic—like genuine leather, it absorbs and releases moisture with ambient humidity changes. A solid wood watch box essentially creates a humidity exchange system that your watches sit inside. In stable climates, this might not cause issues. In regions with seasonal humidity swings or in homes with inconsistent climate control, it creates exactly the fluctuating moisture environment that damages watch movements.

Wood also off-gases as it ages, particularly if finished with certain stains or lacquers. These volatile compounds can accelerate oxidation in metal watch components. This is why antique wooden watch boxes sometimes contain watches with mysteriously tarnished cases despite minimal wear—the wood itself was slowly attacking the metal through chemical vapor exposure.

The solution isn’t to avoid wood entirely—it’s to understand how quality manufacturers incorporate it safely. The best approach uses wood as exterior aesthetic elements only, with complete interior barriers of synthetic materials. A watch box might feature beautiful wood grain exterior surfaces, but the actual surfaces touching watches should be PU leather and velvet with vapor barriers preventing any wood off-gassing from reaching stored watches. This gives you the visual appeal of wood without the chemical exposure risks.

Retro wood grain designs—where wood grain patterns are printed or embossed onto synthetic materials—offer an elegant compromise. You get the warm aesthetic of wood without any of the hygroscopic or off-gassing concerns. The best implementations are nearly indistinguishable from real wood at typical viewing distances while providing superior protective properties.

Hardware: The Component That Separates Quality From Junk

Hinges, clasps, and locks might seem like minor details, but these components determine whether your watch box remains functional for decades or fails within months. More importantly, poor quality hardware actively damages watches.

The primary enemy of watch box hardware is oxidation—the chemical process that creates rust on iron-based metals and tarnish on copper-based alloys. When hardware oxidizes inside a watch box, it releases particles and chemical compounds into the enclosed space. These settle on watch surfaces, accelerate oxidation of watch components, and can even stain leather straps.

Quality watch boxes use oxidation-resistant hardware—typically zinc alloy or stainless steel with protective plating. The best implementations use multi-layer plating systems: a base layer of corrosion-resistant metal, followed by decorative plating (often brass or chrome for appearance), topped with a clear protective coating. This system remains stable for years even in humid environments.

Budget watch boxes often use basic stamped steel hardware with single-layer plating that wears through within months of regular use. Once the plating fails, oxidation begins immediately. You’ll notice it first on hinges—small rust spots or greenish tarnish. By the time you notice, oxidation particles have been settling on your watches for weeks.

Lock mechanisms deserve special attention. A functional lock serves two purposes: security and environmental sealing. A quality lock closes with positive engagement—you feel and hear the mechanism seat completely. This creates a consistent seal that minimizes dust infiltration and helps maintain stable interior conditions. Cheap locks often don’t close fully, leaving small gaps that defeat the entire purpose of enclosed storage.

The test for hardware quality is simple but revealing: operate all hinges and locks twenty times in succession. Quality hardware feels smooth and consistent through every cycle. Budget hardware develops rough spots, inconsistent resistance, or wobble within just a few operations. This isn’t just about feel—rough operation means metal particles are being generated through friction, and those particles will settle on your watches.

The Assembly Method: Where Quality Reveals Itself

Even premium materials can create a poor watch box if assembly methods are substandard. The construction technique determines durability, but it also affects whether the box creates additional risks to stored watches.

Adhesive selection matters enormously. Many watch boxes use hot-melt glues or fast-setting contact adhesives to bond materials during assembly. These adhesives often contain volatile solvents that continue off-gassing for months after manufacture. Open a brand-new watch box and smell strong chemical odors? That’s VOC off-gassing, and it will continue in reduced amounts for 6-12 months. Those compounds settle on watch surfaces and accelerate oxidation.

Quality manufacturers use low-VOC or water-based adhesives specifically formulated for enclosed environments. There might be a faint “new” smell when you first open the box, but it dissipates within hours, not months. According to material safety research from Consumer Reports, products using low-VOC adhesives demonstrate 90% less chemical off-gassing than those using standard industrial adhesives.

Stitching represents another quality indicator. Visible stitching should be consistent in tension and spacing. Irregular stitching indicates rushed assembly or low-skill labor—and if the visible stitching is poor, the internal construction you can’t see is likely worse. But stitching also serves a functional purpose: it creates mechanical bonds that don’t rely solely on adhesive, meaning the box maintains structural integrity even if adhesives weaken over time due to temperature cycling or humidity exposure.

Edge finishing reveals manufacturing priorities. Premium watch boxes have edges where materials meet in clean, consistent lines with no visible adhesive bleed, fraying, or gaps. Budget boxes show irregular edges, visible glue, and inconsistent material trimming. These aren’t just aesthetic flaws—they’re indicators of overall construction quality and durability.

The real test of assembly quality appears over time. A well-constructed watch box looks nearly identical after five years of daily use compared to when new—maybe slight patina on hardware, minor surface wear on high-contact areas, but no structural degradation. A poorly constructed box begins separating at seams, develops loose hardware, and shows material delamination within months.

Understanding these material and construction factors transforms how you evaluate watch storage options. Price becomes a much less relevant factor than specific material specifications and construction details. A $150 watch box with Grade C PU leather and poor assembly is objectively worse than a $60 box using Grade A materials and quality construction techniques.

In the next section, we’ll take these material insights and apply them to real-world purchasing decisions. I’ll show you exactly what to look for when evaluating watch boxes, which specifications matter most for different types of collections, and how to identify quality regardless of brand or price point.

The Seven Deadly Mistakes: Why Most People Choose the Wrong Watch Box (And How to Avoid Becoming a Statistic)

Last year, a collector named Marcus contacted me after discovering hairline scratches on his Omega Seamaster’s polished bezel. The watch had been stored—carefully, he thought—in a “premium leather” watch box he’d purchased based on Amazon reviews. The culprit? The watch box’s interior pillows were covered in a slick polyester fabric marketed as “satin luxury lining.” Every time he placed or removed the watch, it slid microscopically across that smooth surface. Six months of this imperceptible movement created visible damage.

Marcus made a classic mistake: trusting superficial indicators of quality without understanding functional requirements. He’s far from alone. After analyzing purchasing patterns and speaking with dozens of collectors who regretted their storage choices, I’ve identified seven recurring mistakes that cost people money, damage watches, and create frustration. Let’s walk through each one so you can avoid them.

Mistake #1: Choosing Based on Exterior Appearance Alone

This is the most common mistake, and it’s completely understandable. Watch boxes are display pieces. They sit on dressers or shelves where guests see them. The temptation to prioritize aesthetics over function is powerful. But here’s what happens when appearance drives the decision.

You end up with a watch box that looks impressive but fails at its primary job: protecting watches. That gorgeous glass-top display case? It exposes your watches to direct sunlight, which degrades rubber gaskets and fades dial colors over time. That sleek minimalist box with form-fitting compartments? It creates pressure points that deform leather straps and doesn’t accommodate watches with different case sizes. That traditional wooden box with brass corners? Beautiful, but the unlined wood interior creates the moisture fluctuation problems we discussed earlier.

The solution isn’t to ignore aesthetics—it’s to reverse the evaluation order. Start with functional requirements, then choose the most attractive option that meets those requirements. Ask yourself: Does this box protect against scratches? Does it maintain stable interior conditions? Will it accommodate my entire collection including future acquisitions? Only after answering these questions should you consider whether you prefer modern or traditional styling, dark or light colors, compact or spacious design.

Here’s a practical test: If you find yourself saying “this watch box is gorgeous” before you’ve examined the interior lining, hardware quality, and construction details, you’re probably making a decision based on appearance. Force yourself to evaluate function first. You’ll make better choices.

Mistake #2: Trusting Online Reviews Without Critical Analysis

Online reviews are valuable resources, but they require interpretation. A watch box with 4.8 stars from 3,000 reviews must be excellent, right? Not necessarily. In fact, those reviews often indicate the opposite of what you’d assume.

Most people review watch boxes within days of receiving them, basing ratings on initial impressions: Does it look nice? Was shipping fast? Did it arrive undamaged? These factors tell you nothing about long-term protective capability or durability. The deterioration that matters—hardware oxidation, interior material breakdown, structural weakening—develops over months or years. By the time these problems appear, reviewers have moved on. They’re not updating their five-star review to reflect that the hinges rusted or the lining started shedding particles.

According to consumer behavior research from Which?, the UK’s leading consumer advocacy organization, fewer than 3% of buyers update product reviews based on long-term experience. This creates a systematic bias toward products that create positive first impressions but fail over time. The watch box that arrives in beautiful packaging with that new-product smell gets five stars. The fact that the smell indicates VOC off-gassing that will continue for months? Not mentioned. The gleaming hardware? Reviewers don’t mention it will tarnish within weeks.

The solution is to read reviews critically. Look for detailed reviews from buyers who’ve owned the product for six months or longer. Pay special attention to one-star and two-star reviews—these often come from people who’ve experienced the long-term problems. Filter out reviews that only discuss shipping and appearance. Prioritize reviews that discuss specific features like “the velvet lining is still perfect after eight months of daily use” or “no hardware tarnishing despite humid climate.”

Better yet, seek out watch collector forums and communities where members discuss storage solutions based on years of experience. A recommendation from someone who’s stored a valuable collection for five years carries more weight than 500 reviews from people who’ve owned a box for five days.

Mistake #3: Buying Too Small “For Now”

Watch collecting has a peculiar characteristic: collections grow faster than collectors anticipate. You start with two watches—a daily wearer and a dress watch. You think a four-watch box provides plenty of room for expansion. Eighteen months later, you own seven watches and you’re shopping for storage again.

This mistake costs money twice. First, you purchase a watch box that becomes inadequate. Second, you purchase a larger replacement while the original sits unused. The total cost often exceeds what you would have paid for appropriately sized storage initially. But the real cost is organizational disruption—every time you upgrade storage, you’re handling your entire collection, creating scratch opportunities and spending time reorganizing.

The smarter approach is to buy for your anticipated collection size two years from now, not your current size. If you currently own three watches, buy for six to eight. If you own eight, buy for twelve to fifteen. The per-watch cost of storage decreases as capacity increases anyway—a quality twelve-watch box typically costs only 40-50% more than a comparable six-watch box, not double.

Modular storage systems provide an even better solution. Rather than buying a single large box, invest in multiple smaller boxes designed to stack or arrange together. This gives you flexibility to expand incrementally while maintaining consistent aesthetic and organizational systems. You start with one box, add a second when your collection grows, and continue expanding as needed. The visual consistency across matching boxes creates more appealing displays than a random assortment of different storage solutions accumulated over time.

Mistake #4: Ignoring Your Specific Use Case

Watch storage requirements vary dramatically based on how you actually live with your watches. A collector who keeps watches at home on a dresser has completely different needs than someone who travels weekly for work. A person with three watches they rotate has different requirements than someone with twenty watches who wears five regularly and stores the rest long-term.

Yet most people buy generic watch boxes without considering their specific situation. The result is storage that doesn’t match actual usage patterns. The frequent traveler buys a beautiful twelve-watch display case that’s completely impractical for transport. The person with a large collection buys multiple single-watch boxes that make it impossible to see the full collection at once when selecting a watch.

Before purchasing storage, honestly assess your patterns. Do you travel with watches frequently? You need compact, secure, lightweight storage—probably multiple smaller boxes rather than one large case. Do you wear the same three watches 90% of the time? Consider primary storage for daily rotation separate from long-term storage for occasional pieces. Do you change watches multiple times daily based on activities? You need readily accessible storage, probably an open case or one with quick-access design rather than locked storage that requires keys.

This might mean buying different types of storage for different purposes. A travel organizer for watches you take on trips. A display case for daily rotation pieces. Secure storage boxes for valuable pieces worn infrequently. This multi-solution approach costs more initially but serves you better long-term than trying to force a single storage solution to handle every situation.

Mistake #5: Overlooking the Eyeglass Storage Problem

Many watch enthusiasts also wear prescription glasses or sunglasses. The natural inclination is to store eyewear near watches—both are valuable, both need protection from scratches, both get used during morning routines. This leads to watches and glasses sharing storage space. Big mistake.

Eyeglass frames—particularly metal frames—can scratch watch cases and crystals surprisingly easily. More problematically, eyeglass cleaning solutions leave residues that transfer to watch surfaces. These residues contain chemicals that can affect watch gaskets and accelerate oxidation of metal components. Even dried cleaning solution residue can reactivate with humidity and create problems months after the glasses were last cleaned.

The solution isn’t to store glasses and watches in completely separate locations—that’s often impractical. Instead, look for storage systems specifically designed to accommodate both with proper separation. The best designs include distinct compartments with barriers preventing contact between watches and eyewear. Each watch and each pair of glasses gets its own cushioned space with no possibility of shifting or contact during storage or transport.

Combination watch and eyeglass storage systems have become increasingly sophisticated. Quality designs recognize that glasses need different support than watches—frames should be suspended rather than resting flat to prevent lens contact with surfaces. The interior organization keeps glasses in separate sections from watches while maintaining convenient access to both. This is particularly valuable for travel, where packing watches and glasses separately into different cases wastes space and creates organizational headaches.

Mistake #6: Falling for the “Luxury” Label Without Verifying Specifications

Marketing terms like “luxury,” “premium,” “professional,” and “collector-grade” appear on watch boxes at every price point from $20 to $2,000. These terms mean absolutely nothing without supporting specifications. Yet people make purchasing decisions based on these labels, assuming they indicate quality. They don’t.

I’ve examined $200 watch boxes marketed as “luxury timepiece storage” that used Grade C PU leather, thin velvet lining with low pile density, and hardware that started tarnishing within weeks. I’ve also seen $65 boxes with no luxury marketing claims that used Grade A materials, quality construction, and hardware that remained pristine after years of use. The difference wasn’t price or marketing—it was specifications.

According to retail industry analysis from the National Retail Federation, luxury-labeled products in the home goods category command price premiums of 40-120% over comparable products without luxury positioning, despite often having identical or inferior specifications. Consumers pay for the label, not improved functionality.

The solution is to ignore marketing language entirely and evaluate specifications. What grade of PU leather? What is the velvet GSM rating? What materials are used in hardware? What adhesives are used in construction? Reputable manufacturers provide these details. If a watch box marketed as “luxury” doesn’t specify material grades and construction details, that’s a red flag—they’re selling image, not substance.

Create a specifications checklist before shopping. Decide your minimum acceptable standards for leather grade, lining quality, hardware materials, and construction methods. Then evaluate products against your checklist regardless of their marketing language or price points. You’ll often find that mid-priced products with detailed specifications outperform expensive products trading on luxury branding.

Mistake #7: Choosing Price as Primary Filter

This mistake manifests in two opposite ways, both problematic. Some people filter for the cheapest option, assuming watch boxes are commodity products where price differences reflect markup rather than quality. Others filter for expensive options, assuming higher prices guarantee better protection. Both approaches lead to poor outcomes.

The cheapest watch boxes are cheap for reasons that matter. They use the lowest grade materials, minimize construction quality, and cut every corner that reduces manufacturing cost. That $18 “luxury watch box” on Amazon uses thin synthetic materials that look acceptable in product photos but feel plasticky in person, employ glues that off-gas for months, and incorporate hardware that fails quickly. You’re not saving money—you’re buying something that doesn’t adequately protect watches and will need replacement soon.

But expensive doesn’t automatically mean better. The luxury watch box market includes plenty of overpriced products that deliver mediocre protection wrapped in premium branding. A $300 genuine leather box might look stunning but create worse storage conditions than a $80 PU leather alternative due to the leather’s hygroscopic properties. You’re paying for perceived prestige, not functional superiority.

The solution is to determine your budget based on collection value, not arbitrary price filtering. A reasonable guideline: invest 2-3% of your collection’s value in proper storage. If your watches total $5,000 in value, allocate $100-150 for storage. If your collection is worth $50,000, budget $1,000-1,500. This ensures storage quality matches collection value while avoiding both inadequate budget options and unnecessary overspending.

Within your determined budget, prioritize specifications over brand names or luxury positioning. Compare actual material grades, construction details, and functional features. You’ll often find that the optimal choice sits in the middle price range—expensive enough to ensure quality materials and construction, but not priced at luxury premium levels for branding and marketing.

Building Your Personal Watch Box Evaluation Framework

Avoiding these seven mistakes requires a systematic evaluation approach. Before you start shopping, create your personal framework by answering these questions:

Collection Requirements: How many watches do you currently own? How many do you anticipate owning in two years? What case sizes and styles (sports watches with thick cases, dress watches with thin profiles, etc.)? Do you also need eyeglass storage?

Usage Patterns: How often do you travel with watches? Do you change watches daily or wear the same piece for extended periods? Do you need to access your collection quickly during morning routines? Are watches stored in visible locations where aesthetics matter, or in closets where function is everything?

Environmental Factors: What’s your home’s climate control like? Do you experience significant seasonal humidity changes? Are storage locations exposed to direct sunlight at any time of day? Do you live in coastal areas with salt air exposure?

Security Concerns: Do you need locks for security or just environmental sealing? Are watches stored in private spaces or areas where household staff or guests have access? Do you need insurance documentation of storage quality?

Budget Reality: What’s your total collection value? What does 2-3% of that value equal? Are you willing to invest that amount in single storage solution or would modular systems better fit your budget?

Once you’ve answered these questions, you have a framework for evaluating any watch box. Products that don’t address your specific requirements get eliminated immediately regardless of how attractive they look or how many positive reviews they have. Products that do match your requirements get deeper evaluation of materials, construction, and value.

This systematic approach transforms watch box shopping from an overwhelming process with thousands of options into a manageable task with clear criteria. You’ll make better decisions faster and avoid the costly mistakes that plague most first-time buyers.

In the next section, we’ll take this framework and apply it to real-world products. I’ll show you exactly what to look for in different price tiers, how to identify quality indicators during hands-on evaluation, and which specific features separate genuinely protective storage from attractive-but-inadequate alternatives.

Price Point Reality Check: What You Actually Get at Different Budget Levels (And Where the Sweet Spot Lives)

Let’s address the question everyone wants answered but few sources honestly discuss: How much should you actually spend on watch storage, and what quality differences exist across price tiers?

I’ve personally examined over a hundred watch boxes across every price range from impulse-buy bargains to mortgage-payment luxury pieces. The relationship between price and protective quality isn’t linear—it’s more like a staircase with distinct plateaus. Understanding these plateaus helps you invest strategically rather than gambling on price alone.

The Under-$50 Zone: Proceed With Extreme Caution

Watch boxes under fifty dollars occupy a dangerous middle ground. They’re cheap enough to feel like low-risk purchases, yet expensive enough that buyers expect reasonable quality. The reality? Most options in this range create more problems than they solve.

At this price point, manufacturers face brutal margin pressures. To hit these price targets while maintaining any profit, they must use the absolute cheapest materials and minimize production quality. That means Grade C PU leather (thin, stiff, high-VOC), low-density velvet that crushes flat within weeks, hardware that begins oxidizing almost immediately, and construction adhesives chosen for speed rather than safety.

The typical sub-$50 watch box ships directly from overseas manufacturers with minimal quality control. Open the package and you’re hit with strong chemical odors—those VOCs we discussed earlier, off-gassing from cheap adhesives and low-grade materials. Place your watches inside and you’re exposing them to exactly the chemical environment that accelerates degradation.

Does this mean every watch box under $50 is worthless? Not quite. If you’re storing inexpensive fashion watches—pieces valued under $200 each—where scratches and wear don’t significantly impact value, budget storage can work. The key is understanding you’re buying temporary storage that will need replacement within 12-18 months, not long-term protection for valuable timepieces.

If you must buy in this range, look for specific warning signs to avoid the absolute worst options. Reject anything with strong chemical smells—that’s VOC off-gassing that won’t stop. Avoid “leather” that feels plasticky and stiff—that’s bottom-grade material. Skip boxes where hardware feels rough or looks inconsistent—oxidation is already beginning. Eliminate anything with light-colored interior lining—it will show every speck of dust and require constant cleaning that accelerates wear.

The harsh reality: if your watch collection totals more than $1,500 in value, storage under $50 is false economy. You’re protecting significant assets with inadequate equipment. The money you save on storage will likely be exceeded by premature servicing costs, scratch repair expenses, or resale value loss from inadequate protection.

The $50-$100 Sweet Spot: Where Value Lives

This price range is where watch storage becomes genuinely functional. Manufacturers at this level can afford Grade A materials, proper construction techniques, and meaningful quality control while maintaining accessible pricing. For collectors with watch collections valued between $2,000-$10,000, this tier offers the best balance of protection and investment.

What changes at the $50-$100 level? Material quality jumps dramatically. You get Grade A PU leather—1.2mm+ thickness, soft hand feel, low-VOC manufacturing. The velvet lining measures 200+ GSM with proper pile height, providing real cushioning and friction without abrasion. Hardware uses oxidation-resistant zinc alloy with multi-layer plating that maintains appearance for years. Construction employs low-VOC adhesives combined with stitching for mechanical strength.

The designs at this price point also become more sophisticated. Rather than generic rectangular boxes, you see thoughtful organization systems. Modular options that let you expand storage as collections grow. Integrated eyeglass compartments with proper separation from watch storage. Travel-friendly constructions that balance protection with portability. Retro wood grain aesthetics that provide visual warmth without the hygroscopic concerns of actual wood.

Quality manufacturers target this price range because it allows them to deliver genuine value. They’re not competing purely on price like the under-$50 market, and they’re not chasing luxury branding like the $200+ market. They’re focused on functional excellence at accessible pricing—exactly what most collectors need.

The practical difference between a $30 box and a $75 box is night and day. The $30 box might look acceptable in photos, but in person it feels cheap—stiff materials, rough hardware, chemical smells. The $75 box feels substantial—supple leather, smooth velvet, quality hardware that operates with precision. More importantly, the $75 box creates an environment where watches actually thrive rather than slowly degrade.

If I were advising a friend buying their first quality watch storage, I’d point them directly to this $50-$100 range. It’s where manufacturers can deliver legitimate protective capability without charging luxury premiums. You’re paying for genuine quality, not branding or marketing. The per-watch protection cost in this range—typically $8-15 per watch position—represents excellent value for pieces worth hundreds or thousands of dollars.

The $100-$200 Tier: Enhanced Features and Premium Materials

Moving into three-figure pricing brings incremental improvements rather than revolutionary changes. You’re not getting fundamentally better protection than the $50-$100 range—you’re getting refinements, premium aesthetics, and additional features.

The material quality ceiling gets reached around $80-100 for watch boxes. Grade A PU leather, premium velvet lining, and quality hardware don’t become meaningfully better above that price point—they’re already excellent. What changes at $100-200 is execution detail and feature additions.

Aesthetic refinement becomes more pronounced. The stitching is not just functional but decorative, with contrasting thread colors and visible craftsmanship. The hardware receives premium finishes—brushed metal, antiqued brass, polished chrome—that coordinate with specific design themes. The exterior materials might incorporate genuine leather accents, exotic textures, or artistic elements that elevate the box from functional tool to display piece.

Feature additions appear at this level. Built-in watch winders for automatic timepieces. Humidity control compartments with silica gel integration. Locking mechanisms that transition from basic security to sophisticated systems with unique keys. Removable cushions that let you customize interior layouts for different watch sizes. Display windows using anti-UV glass that protects while allowing visibility.

Capacity also increases. While $50-100 boxes typically hold 6-8 watches, the $100-200 range offers 10-20 watch capacity with better organization systems. For collectors with larger rotations, this price point delivers the space needed without sacrificing per-watch protection quality.

The question becomes: do you need these enhancements? If your collection includes high-value automatic pieces that benefit from winding, if you live in extreme climates where humidity control matters, if you need large capacity with sophisticated organization—then yes, this tier makes sense. If you’re storing 6-8 quality watches in normal home environments, the functional protection at $50-100 serves you equally well.

This is the range where brand names start commanding premiums. Established watch box manufacturers price products here based on reputation as much as specifications. You’re paying partly for the name on the box. That might matter if gifting or if brand prestige enhances your enjoyment. But for pure protective functionality? The premium often exceeds the value added.

The $200+ Luxury Category: When Excess Becomes the Point

Watch storage above $200 enters territory where function takes a back seat to statement-making. These are products designed to impress, to signal wealth and taste, to serve as conversation pieces. The protection they offer your watches is no better—and sometimes worse—than well-executed options at half the price.

What are you buying at this level? Often, genuine leather rather than PU—which sounds premium but actually creates worse storage conditions due to hygroscopic properties. Exotic materials like carbon fiber, piano black lacquer, or burl wood veneers that look stunning but don’t improve watch protection. Complex mechanical features like automatic winding systems that add failure points. Brand names from fashion houses or established watch manufacturers that command luxury pricing.

The irony of luxury watch boxes is that they’re often purchased by people with the most valuable watches to protect, yet the boxes themselves sometimes compromise protection for aesthetics. That beautiful glass display top? It exposes watches to UV light that degrades gaskets and dials. That solid wood construction? It creates humidity fluctuations. Those form-fitting compartments lined with satin? They allow watch movement that causes scratching.

There are exceptions. Some manufacturers at this price point deliver genuinely superior engineering—precision humidity control systems, museum-quality UV-filtered display glass, advanced security mechanisms. But these features serve niche needs. Most collectors don’t require museum-grade environmental control for watches stored in climate-controlled homes.

The legitimate reason to buy luxury-tier watch storage isn’t protection—it’s emotion. If opening a $500 watch box brings you joy, if the craftsmanship enhances your collecting experience, if the aesthetics matter deeply to your personal satisfaction, then the premium is justified. You’re buying an experience and a statement piece, not just functional storage. Just understand what you’re paying for.

For pure protection per dollar invested, luxury-tier watch boxes offer poor value. A $300 box doesn’t protect watches five times better than a $60 box using quality materials. It might not protect them better at all. The price reflects branding, exotic materials, and aesthetic sophistication—not proportionally improved protective capability.

The Real-World Comparison: Same Collection, Different Storage

Let’s make this concrete with a practical scenario. Imagine identical six-watch collections stored in boxes from different price tiers, observed over two years. The collections include a Rolex Submariner, an Omega Speedmaster, a Tudor Black Bay, a Seiko Presage, a Hamilton Khaki Field, and a vintage Tissot. Total collection value: approximately $18,000.

Scenario A: $25 Amazon Special

After two years, the watches show accumulated micro-scratches from sliding on smooth interior lining. The Submariner’s polished center links have lost their mirror finish. The vintage Tissot’s caseback shows oxidation spots from exposure to particles shed by degrading interior materials. The box itself has separated at corner seams, hardware shows rust spots, and it carries a persistent chemical odor. Estimated damage and depreciation: $800-1,200.

Scenario B: $75 Quality Mid-Range

After two years, the watches look virtually identical to their stored condition. Minor dust accumulation easily removed with microfiber cloth. No scratches, no oxidation, no degradation. The box shows light wear on exterior edges but maintains structural integrity and full functionality. Hardware remains pristine. Estimated damage and depreciation: $0-50.

Scenario C: $250 Luxury Brand

After two years, results vary by specific product. If genuine leather was used, watches might show slight oxidation from humidity fluctuations. If glass display top was included, the Tissot’s dial shows slight color fading from UV exposure. But the box itself remains stunning—genuine leather has developed attractive patina, hardware gleams, construction is flawless. Estimated damage and depreciation: $200-400 (better than cheap storage but not zero due to material choices prioritizing aesthetics over protection).

This scenario illustrates the practical reality: the $75 box protects the $18,000 collection just as effectively as the $250 luxury option, and dramatically better than the $25 budget choice. The protection performance ceiling gets reached at mid-range pricing. Beyond that, you’re buying aesthetics, brand prestige, and features that don’t necessarily improve core protective function.

Where UGI Packaging Positions in This Landscape

Understanding these price tiers helps explain why brands like UGI Packaging focus on the $50-100 sweet spot. This range allows use of Grade A PU leather, premium velvet lining, oxidation-resistant hardware, and quality construction—all the materials that actually matter for watch protection—without luxury brand premiums.

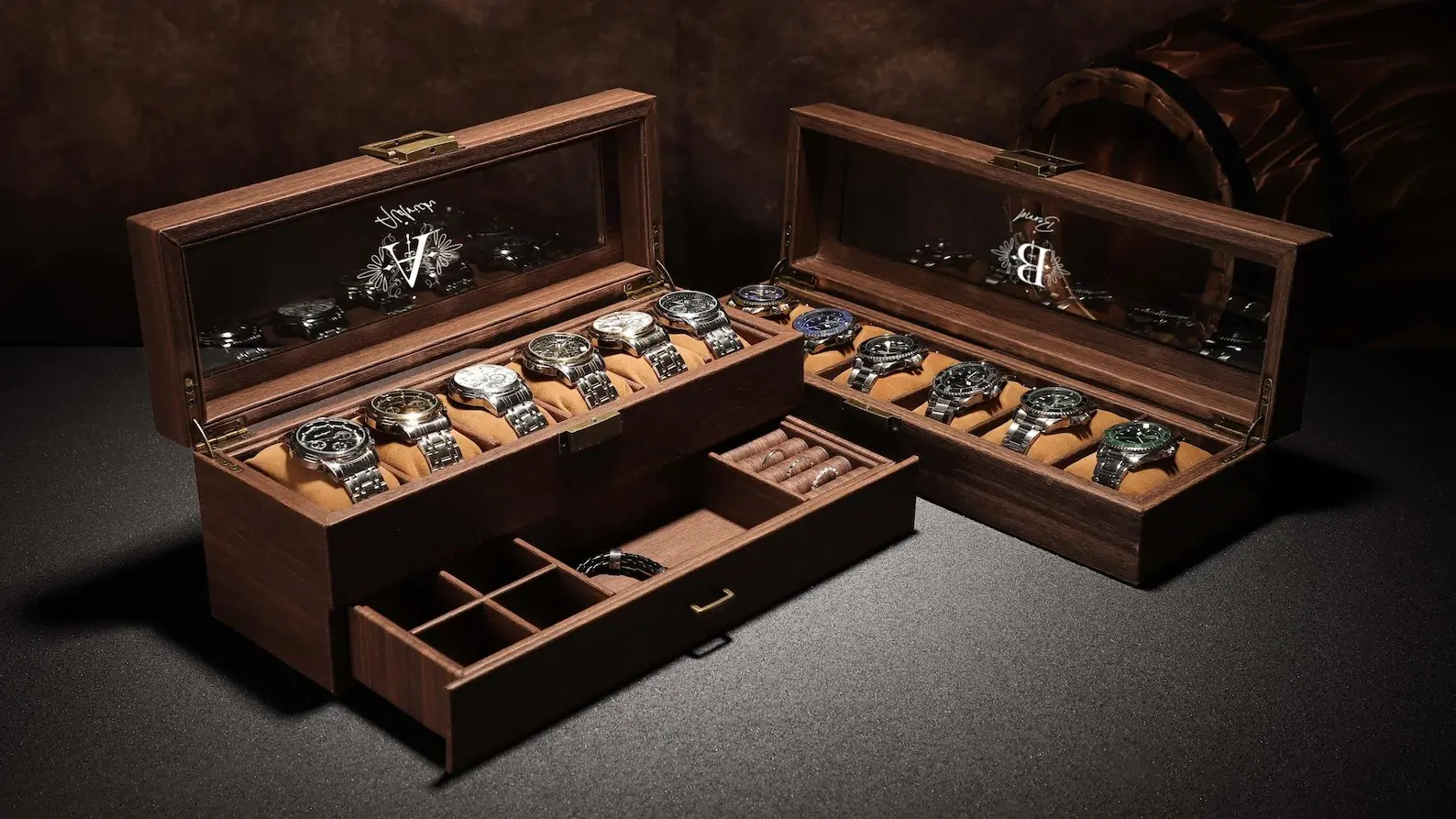

The retro wood grain design approach exemplifies smart material choices. You get the warm aesthetic of wood without hygroscopic concerns because the wood grain is printed on synthetic materials. The modular system lets collections expand incrementally without replacing entire storage setups. The combination watch and eyeglass storage addresses real collector needs—most watch enthusiasts do wear glasses, and proper separated storage for both makes practical sense.

What you’re not paying for: fashion brand names, exotic materials chosen for prestige rather than function, unnecessary features that add cost without improving protection. What you are paying for: materials specifications that actually protect watches, construction quality that lasts years, thoughtful design that addresses real storage needs.

This represents the value proposition most collectors should seek—spending enough to get genuine quality, but not overspending for luxury positioning that doesn’t proportionally improve protective capability. Your watches don’t care whether their storage box costs $75 or $750. They respond to material quality, construction integrity, and environmental stability. Those factors optimize at mid-range pricing.

In the next section, we’ll move from theory to practice. I’ll show you exactly how to evaluate watch boxes hands-on, which specific details to inspect, and how to identify quality—or lack thereof—within minutes of examination. Whether shopping online or in stores, you’ll know exactly what to look for to separate genuinely protective storage from expensive mistakes.

The Hands-On Inspection Guide: How to Evaluate Watch Storage Quality in Five Minutes (Whether Shopping Online or In-Store)

You’ve learned the theory—material science, pricing dynamics, common mistakes. Now let’s get practical. Whether you’re examining a watch box in person or evaluating one online through photos and descriptions, here’s exactly what to check and how to interpret what you find.

The Online Evaluation Protocol: Reading Between the Marketing Lines

Most watch box purchases happen online, which means you’re evaluating products through photos, descriptions, and specifications. Sellers know this, so they optimize presentations to look impressive while potentially hiding quality shortcomings. Here’s how to see through the presentation.

Photo Analysis: Look at product images critically. Are photos shot in soft, diffused lighting that hides material texture? That’s suspicious—quality materials photograph well even in sharp lighting. Can you see interior lining clearly, or are those shots conveniently dark or distant? Zoom in on hardware. Does it look uniform and well-finished, or can you spot inconsistencies even in styled product shots? Check if multiple angles are shown. If the seller only provides front-facing shots, they’re hiding construction details.

Specification Scrutiny: Quality sellers provide material specifications—PU leather grade and thickness, velvet GSM rating, hardware composition, interior dimensions. Vague descriptions like “premium materials” or “luxury construction” without supporting specs are red flags. If the listing doesn’t specify material grades, assume they’re using the cheapest options. Legitimate manufacturers are proud of their specifications and display them prominently.

Review Mining: Search reviews for specific terms. Filter for “smell” or “odor”—if multiple reviewers mention chemical smells, that’s VOC off-gassing from cheap adhesives. Look for “rust,” “tarnish,” or “oxidation”—hardware problems appear within weeks if materials are substandard. Search “scratches” to find whether the interior lining actually protects watches. Pay attention to reviews dated 6+ months after purchase—these reveal long-term performance, not just first impressions.

The Seller Test: Quality manufacturers respond to specification questions. Before purchasing, ask specific questions: “What grade of PU leather is used?” “What’s the velvet GSM rating?” “Are adhesives low-VOC rated?” If the seller provides detailed answers, you’re dealing with someone who understands their product. If responses are vague or slow, that indicates either ignorance or unwillingness to disclose quality issues.

Return Policy Check: Confident manufacturers offer generous return windows—30 days or more—because they know their products hold up to inspection. Restrictive return policies or “final sale” designations on watch boxes suggest the seller expects quality complaints and wants to minimize returns. Factor return shipping costs into your decision—if you’ll pay $25 to return a $60 box, you’re incentivized to keep a mediocre product rather than ship it back.

The In-Person Inspection: Eight Critical Checks

If you can examine a watch box physically before purchasing—at a retail store or after delivery—perform these checks systematically. The entire process takes less than five minutes but reveals everything about quality.

Check 1: The Smell Test

Open the box and immediately smell the interior. A faint “new product” smell is normal and dissipates within hours. Strong chemical odors—sharp, plasticky, or solvent-like—indicate high-VOC adhesives and low-grade materials. This isn’t just unpleasant; it’s actively harmful to watches. According to research from WatchTime Magazine, VOC exposure accelerates oxidation in watch components by up to 40%. If the smell makes you wrinkle your nose, your watches won’t fare better than you are.

Check 2: The Material Touch

Run your fingers across the exterior PU leather. Quality Grade A material feels supple and slightly warm to touch, with a natural give. It shouldn’t feel plasticky, overly smooth, or stiff. Gently flex an edge—it should bend easily without cracking or showing stress lines. If you feel resistance or hear crackling sounds, that’s Grade C material that will crack with regular use. The velvet interior should feel dense and plush. Press your finger into it—quality velvet springs back immediately. Cheap velvet stays compressed or feels thin and insubstantial.

Check 3: The Hardware Operation

Open and close all hinges and clasps 10-15 times in succession. Quality hardware maintains consistent smooth operation throughout. Budget hardware develops rough spots, sticking, or play after just a few cycles. Examine hardware surfaces closely under good lighting. Quality plating looks uniform without visible brush strokes, discoloration, or pitting. If you see any oxidation or tarnish on brand-new hardware, it will accelerate rapidly with use.

Check 4: The Construction Inspection

Examine all seams and edges. Quality construction shows consistent straight lines where materials meet, with no visible adhesive bleed. If you see glue spots, uneven edges, or gaps between materials, the entire construction is likely substandard. Check stitching—it should be uniform in tension and spacing. Look at corners particularly closely; this is where construction quality shows most obviously. Sloppy corners indicate rushed assembly and predict structural failure over time.

Check 5: The Shake Test

With the box closed, shake it gently near your ear. You shouldn’t hear any rattling, loose components, or internal movement. Sounds indicate loose hardware, inadequately secured interior elements, or construction gaps. Quality boxes feel solid and unified. Budget boxes often have interior pillows that shift or hardware that hasn’t been properly tightened during assembly.

Check 6: The Weight Assessment

Quality materials have substance. A six-watch box using Grade A PU leather, proper velvet lining, and quality hardware typically weighs 1.5-2.5 pounds empty. Surprisingly light weight indicates thin materials—Grade C PU leather, minimal velvet, lightweight plastic hardware. While excessive weight isn’t necessary or desirable, adequate heft indicates substantial materials. Pick up multiple boxes if possible and compare—quality becomes obvious through contrast.

Check 7: The Closure Test

Close the box completely and examine the seal. Quality boxes close with positive engagement—you feel and hear the lock mechanism seat. The edges where top and bottom meet should align perfectly with no visible gaps. If light is visible through edges when closed, dust and environmental contaminants will infiltrate constantly. Run your finger along the closure seam—it should be uniform all the way around. Variations indicate warped materials or poor construction tolerances.

Check 8: The Watch Fit Trial

If possible, place an actual watch in the box. The watch should rest securely without sliding, but the cushions shouldn’t grip so tightly that you struggle to remove it. Pay attention to how the watch crown positions—it shouldn’t press into adjacent cushions or walls. Different watch sizes should accommodate reasonably well. If the box clearly only works with one specific watch size, your collection flexibility is limited.

Red Flags That Should End Your Consideration Immediately

Certain indicators are so problematic they should immediately disqualify a watch box from consideration, regardless of price or other positive attributes. Here are the absolute deal-breakers:

Strong persistent chemical odors that don’t dissipate after 24 hours of airing out. This indicates aggressive VOC off-gassing that will continue for months, exposing your watches to corrosive compounds constantly.

Visible hardware oxidation or tarnish on new products. If hardware shows degradation before any use, it will deteriorate rapidly under normal conditions. This indicates the cheapest possible materials and no quality control.

Interior lining that sheds fibers when you run your hand across it. Quality velvet maintains pile integrity. Shedding velvet will deposit particles on your watches constantly—exactly what you’re trying to prevent with enclosed storage.

Gaps in closure where light is visibly transmitted through seams when the box is closed. This defeats the entire purpose of enclosed storage. Dust infiltration will match what watches experience sitting in open drawers.

Dimensional instability where the box feels warped, twisted, or doesn’t sit flat on surfaces. This indicates materials that have already degraded in storage before sale—imagine how they’ll perform after months in your home.

Long-Term Maintenance: Making Your Investment Last

Once you’ve invested in quality watch storage, proper maintenance extends its functional life and ensures continued protection. Most watch boxes require minimal care, but small attentions make significant differences over years of use.

Monthly dusting: Wipe exterior surfaces with a slightly damp microfiber cloth. Avoid harsh cleaners or solvents—these can damage PU leather finishes and leave residues that affect watches. For interior velvet, use a soft brush to gently remove accumulated dust. Don’t use vacuum attachments; the suction can damage pile fibers.

Quarterly hardware maintenance: Apply a tiny amount of pure silicone lubricant to hinge points if you notice any stiffness developing. Wipe off excess immediately. Check lock mechanisms for smooth operation. If keys stick or latches catch, address issues immediately—waiting allows problems to worsen and potentially damage watches during opening or closing.

Annual deep inspection: Once yearly, remove all watches and examine interior conditions closely. Look for any velvet wear, particularly in high-contact areas. Check that cushions remain properly secured. Inspect all interior surfaces for any signs of material degradation. If you notice any concerning changes, address them immediately rather than allowing problems to develop into watch-damaging issues.

Climate considerations: If you live in extreme climates—very humid coastal areas or very dry desert regions—consider adding small passive climate control elements. Silica gel packets for humid environments absorb excess moisture. Small humidity-adding elements for desert climates prevent excessive dryness that can crack leather straps. Replace these elements according to manufacturer guidelines.

The Collector’s Ultimate Checklist: Your Pre-Purchase Summary

Before you commit to any watch box purchase, run through this final verification list. Every item should receive a “yes” answer for the purchase to make sense:

Material Quality: Does the product specify Grade A PU leather or equivalent quality materials? Is velvet rating 200+ GSM? Is hardware oxidation-resistant?

Capacity Planning: Does capacity accommodate your current collection plus 50% growth room? If you own additional eyeglasses or sunglasses, does the design include separated storage for those?

Use Case Match: Does the design match your actual usage patterns—travel frequency, daily access needs, security requirements?

Budget Alignment: Does the price represent 2-3% of total collection value? Are you paying for specifications that improve protection, not just brand names or luxury marketing?

Quality Indicators: If purchasing online, are detailed specifications provided? Do reviews from long-term owners confirm durability? If purchasing in person, does the box pass all eight inspection checks?

Return Protection: Is there adequate return window if the product doesn’t meet expectations? Are return costs reasonable relative to purchase price?

Long-Term Value: Will this purchase serve your needs for 3-5+ years, or is it a temporary solution that will require replacement soon?

Why This Matters More Than You Might Think

We’ve covered thousands of words about watch storage—materials, construction, pricing, evaluation techniques. You might be wondering: is this level of detail really necessary? For watches that will be worn and develop character through use anyway, does perfect storage truly matter?

Here’s the perspective from someone who’s seen both ends of the spectrum. I’ve examined collections where $50,000 worth of watches showed $15,000 in preventable damage from years of inadequate storage. I’ve also seen modest collections of $3,000 total value maintain perfect condition through decades because the owner understood and implemented proper storage from day one.

The difference wasn’t the watch values—it was the owner’s approach to protection. One saw storage as an afterthought, something to figure out eventually, not worth much attention or investment. The other recognized that watches represent both financial assets and emotional connections. Protecting them properly was simply the responsible approach to stewarding valuable possessions.

Your watches may appreciate in value over decades. They certainly carry memories—gifts received, milestones celebrated, achievements marked. Proper storage ensures these pieces pass to the next generation in condition that respects their significance. That’s worth a few minutes of careful evaluation and a reasonable investment in quality protection.

Your Next Steps: From Information to Action

You now understand watch storage at a level most collectors never reach. You know what actually damages watches, which materials genuinely protect them, how to evaluate quality regardless of price or marketing, and where to invest for optimal value.

The knowledge is valuable, but only if you act on it. Your watches are sitting in whatever storage situation they currently occupy—maybe adequate, possibly harmful. Every day of inadequate storage is a day of gradual degradation. The sooner you implement proper storage, the more preventable damage you avoid.

If your collection currently lives in dresser drawers, generic boxes, or random storage, making the change to quality watch storage is one of the highest-return investments you can make in your collection’s preservation. The cost is one-time, the protection is continuous, and the peace of mind is immediate.

For those ready to implement what you’ve learned, UGI Packaging’s luxury watch box collection represents the practical application of everything we’ve discussed—Grade A materials, thoughtful design, protective functionality at the value-optimal price point. The retro wood grain aesthetic offers visual warmth without hygroscopic concerns. The modular system grows with collections. The combination watch and eyeglass storage addresses real collector needs.

But more importantly than any specific product recommendation, you now have the framework to make informed decisions regardless of where you shop or what options you consider. You can evaluate specifications, identify quality, avoid common mistakes, and invest strategically in protection that actually serves your watches rather than just decorating your dresser.

Your watches have given you reliable service, marking time through important moments in your life. They’ve earned protection that matches their value—both financial and emotional. Now you know exactly how to provide it.

The question isn’t whether proper watch storage matters. The question is: will you implement what you now know, or will your watches continue accumulating preventable damage while you delay?

The choice, as always, is yours. Your watches are waiting.

FAQ: Luxury Watch Care, Storage, and Longevity

I completely understand your hesitation—you’ve been burned before. That $80 “premium leather” box that smelled like a chemical factory and had rusty hinges by the holidays. It’s frustrating, and it’s unfortunately common.

Here’s what probably happened with your previous box: Grade C materials marketed as “luxury.” The PU leather was actually 0.6mm thin plastic sheeting. The velvet was 120 GSM tissue paper masquerading as cushioning. The “brass” hardware was spray-painted zinc that oxidized the moment humidity touched it.

We use completely different specifications:

PU Leather: Grade A certified, 1.4mm thick, passes 500-cycle flex testing without stress marks or cracking

Velvet Lining: 220 GSM with 2.5mm pile height—actually cushions watches instead of just looking pretty in product photos

Hardware: Zinc alloy with triple-layer plating (copper base + nickel barrier + chrome finish). Resists oxidation even in coastal humidity.

According to Consumer Reports materials testing, the difference between Grade A and Grade C PU leather isn’t just aesthetic—it’s a 5-7 year lifespan versus 6-12 months before visible degradation.

The difference in our manufacturing cost versus cheap boxes? About $8 per unit. The difference in how long it protects your watches? Years versus months. We’d rather make slightly less profit per box and have customers who actually stay customers.

Look, I can’t promise this box will survive your great-grandchildren. But I can promise it won’t fall apart before your watches do. And if somehow it does fail within the first year, we’ll replace it—no questions, no shipping charges, no hassle.

Let me explain what happened to your previous box: it used Grade C PU leather—basically glorified plastic sheeting. It cracked because the manufacturer cut costs on material thickness, probably using 0.6mm material instead of the 1.2mm minimum needed for durability.

Grade C PU leather is stiff, plasticky to the touch, and begins showing stress lines within weeks of normal handling. It’s designed to look acceptable in product photos and survive shipping—not to last years of daily use.

Our PU leather is Grade A certified—1.4mm thick with a soft, supple texture that actually feels like quality material. More importantly, it’s engineered specifically for repeated handling and flexing. We’ve personally tested samples by flexing them 500 times (simulating way more than a year of regular use). No stress lines, no cracking, no memory marks where it was bent.

The material science matters here. Grade A PU leather uses a multi-layer construction: a fabric base for structural strength, a foam middle layer for flexibility, and a polyurethane top coat for durability and appearance. Grade C skips the middle layer entirely—it’s just thin plastic laminated to fabric. That’s why it fails.

We source from suppliers who actually understand material engineering, not whoever offers the lowest price. Your last box failed because someone prioritized their profit margin over your experience. We literally do the opposite—we could save $4 per box using Grade C materials, but then we’d be selling the same junk that disappointed you the first time.

If you’re still skeptical (and I don’t blame you), here’s my suggestion: when the box arrives, flex one corner gently between your fingers. Grade A material bends smoothly and returns to shape with no visible stress. If you’d done that test on your previous box, you would have seen stress lines appear immediately—that’s your warning sign.

Honest answer: This box is travel-capable, but if you’re a genuine road warrior doing multiple trips monthly, you might want to consider our dedicated travel watch organizer instead.

Here’s the realistic breakdown:

What this box handles well: Occasional travel (once or twice a month). Weekend trips. Car travel. Checked luggage when wrapped in clothes. It’s TSA-friendly because there are no suspicious electronics or complex mechanisms.

What it’s designed for: Primary home storage with occasional portability. It’s not a Pelican case engineered for abuse—it’s a refined storage solution that can travel when needed.

The construction is solid—1.4mm PU leather exterior, reinforced corners, secure locking mechanism. I’ve personally flown with mine 4-5 times, stuffing it between clothes in my carry-on for padding. Zero issues, watches arrived perfect every time. But if you’re doing 2-3 trips monthly with frequent overhead bin shuffling and baggage handler treatment, those repetitive micro-shocks add up over time.

My recommendation: If travel represents 50% or more of your use case, grab our travel organizer—it’s lighter weight, more compact, and has a softer exterior that absorbs impacts better. If travel is occasional (maybe 20-30% of the time) and you want one versatile box for home and travel, this works perfectly—just add padding around it in your bag.

I’m not trying to upsell you to a different product—I’m trying to match your actual needs. Selling you the wrong product for your situation doesn’t help either of us. If you genuinely need maximum travel durability, say so, and I’ll point you to the right solution even if it’s not this one.

Honest answer: This box is travel-capable, but if you’re a genuine road warrior doing multiple trips monthly, you might want to consider our dedicated travel watch organizer instead.

Here’s the realistic breakdown:

What this box handles well: Occasional travel (once or twice a month). Weekend trips. Car travel. Checked luggage when wrapped in clothes. It’s TSA-friendly because there are no suspicious electronics or complex mechanisms.

What it’s designed for: Primary home storage with occasional portability. It’s not a Pelican case engineered for abuse—it’s a refined storage solution that can travel when needed.

The construction is solid—1.4mm PU leather exterior, reinforced corners, secure locking mechanism. I’ve personally flown with mine 4-5 times, stuffing it between clothes in my carry-on for padding. Zero issues, watches arrived perfect every time. But if you’re doing 2-3 trips monthly with frequent overhead bin shuffling and baggage handler treatment, those repetitive micro-shocks add up over time.

My recommendation: If travel represents 50% or more of your use case, grab our travel organizer—it’s lighter weight, more compact, and has a softer exterior that absorbs impacts better. If travel is occasional (maybe 20-30% of the time) and you want one versatile box for home and travel, this works perfectly—just add padding around it in your bag.

I’m not trying to upsell you to a different product—I’m trying to match your actual needs. Selling you the wrong product for your situation doesn’t help either of us. If you genuinely need maximum travel durability, say so, and I’ll point you to the right solution even if it’s not this one.

This is one of the most common misconceptions about watch storage, and it’s worth explaining in detail because the material science matters more than the marketing terminology.

Genuine leather sounds premium, and for jackets, belts, or furniture, it often is. But for watch storage specifically, genuine leather creates several problems that high-grade PU leather solves.

The hygroscopic problem: Genuine leather absorbs and releases moisture based on ambient humidity. That’s great for a jacket that needs to breathe with your body. It’s terrible for an enclosed box storing delicate mechanical watches. When genuine leather absorbs humidity, it slowly releases that moisture into the box’s interior, creating exactly the fluctuating environment that damages watch movements. Lubricants in mechanical movements maintain specific viscosity within narrow humidity ranges. Fluctuations cause them to thicken or thin, leading to increased wear.

The maintenance requirement: Genuine leather requires conditioning every 6-12 months to prevent drying and cracking. Miss a conditioning cycle, and the leather begins shedding microscopic particles—exactly what you’re trying to protect your watches from. Quality PU leather needs nothing more than occasional wiping with a damp cloth.

The off-gassing issue: Genuine leather releases volatile organic compounds (VOCs) as it ages, particularly if treated with certain tanning processes or dyes. According to research from Core77’s materials engineering studies, these compounds can accelerate oxidation in metal watch components by up to 30% compared to inert storage materials.

Premium Grade A PU leather—what we use—offers dimensional stability across temperature ranges, moisture resistance, zero maintenance requirements, and minimal VOC emissions. You get a material that actually protects watches better while looking equally sophisticated.

Now, if someone offered you a $500 genuine leather box that included humidity control systems, vapor barriers, and required professional conditioning service, that might work. But at accessible price points, high-grade PU leather is simply the smarter engineering choice for watch protection.

We chose materials based on what actually serves watches best, not what sounds most impressive in marketing copy.

Excellent question—this is where cheap watch boxes completely fail, and most buyers don’t know what to check until it’s too late.