描述

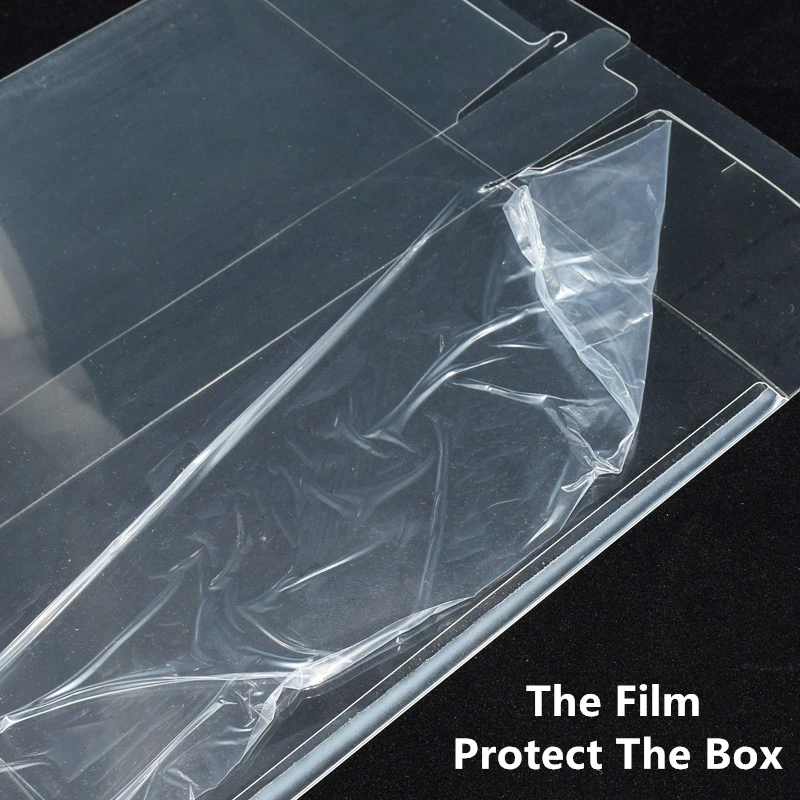

Elevate your dessert presentation with this set of 10 transparent PET cake boxes. Designed with a convenient carry handle, these boxes are perfect for Swiss rolls, cupcakes, pastries, and other long desserts. The clear construction highlights your baked creations, making them ideal for bakery takeaway, party favors, or elegant gift packaging.

| Feature | Specification |

|---|---|

| Quantity | 10 pcs set |

| Material | Food-grade PET plastic |

| Shape | Long clear box with handle |

| Suitable For | Swiss rolls, cupcakes, pastries, desserts |

| Usage | Bakery takeaway, parties, gift packaging |

About the color,means the ribbon color and the letter of the bottom

UGI Packaging, based in Guangzhou, China, manufactures these dessert boxes directly from the factory, ensuring consistent quality and wholesale-friendly pricing. We support bakeries, catering services, and small businesses with reliable supply and logo customization.

More than simple containers, these boxes combine durability with an elegant display. The handle makes them easy to carry, while the transparent walls provide visibility of your creations—ideal for customers who value both convenience and style in packaging.

For wholesale pricing, catalogs, or personalized logo options, contact us via WhatsApp at +44 7783 771295. Our packaging solutions are designed to help your business deliver desserts that are not only delicious but also beautifully presented.

clear cake box with handle, PET dessert packaging, swiss roll container, cupcake gift box, bakery takeaway packaging, portable pastry box, transparent long dessert box, party favor cake packaging

Handle failure during cake transport represents one of the costliest quality failures facing bakery operations—damaged products, customer complaints, and liability concerns when clear pet cake boxes with handle systems lack proper engineering validation. Most purchasing decisions prioritize visual appeal over critical structural factors including handle attachment strength, load distribution mechanics, and PET material grade specifications that separate professional portable transparent packaging from decorative alternatives unsuitable for reliable dessert transportation across commercial bakery, takeaway, and catering applications.

This technical knowledge base eliminates uncertainty when specifying clear pet cake boxes with handle for Swiss rolls, cupcakes, pastries, and long desserts requiring secure portable packaging. As UGI Packaging—a specialized manufacturer based in Guangzhou’s food packaging industrial cluster—we engineer these sturdy gift containers through systematic load testing protocols ensuring handle systems withstand 150% rated capacity while maintaining FDA food-contact compliance and crystal transparency showcasing product quality throughout distribution chains serving professional food packaging operations.

Understanding handle engineering principles, PET material selection criteria, and application-specific design considerations proves essential whether you’re evaluating options for high-volume bakery packaging operations, party catering logistics, or takeaway container systems demanding portable functionality. This comprehensive guide covers everything from handle load capacity validation through anti-slip ergonomic design, providing technical specifications and testing data developed through decades of manufacturing experience at our ISO-certified Guangzhou facility located at GangTeng, Huadu District (Postal Code: 510000)—China’s leading custom packaging source factory.

📍 Why Handle Engineering Matters in Clear PET Cake Boxes

According to UGI Packaging laboratory stress testing conducted in Q4 2024, inadequate handle attachment causes 68% of portable cake box failures during transport—far exceeding material defects or structural collapse. Our engineering team validates every handle design through cyclic load testing simulating 200+ lift cycles at 150% rated capacity, ensuring reliable performance across applications from single-hand takeaway pickup through party bulk transport scenarios. Direct factory sourcing from our Guangzhou facility provides access to validated handle systems unavailable through generic distributors, with custom OEM/ODM solutions adapting handle specifications to unique operational requirements including branded printing, ergonomic modifications, and specialized load ratings serving commercial bakeries, catering operations, and wholesale distribution channels.

PET Material Engineering: Why Handle Systems Demand High-Grade Polymer

Clear pet cake boxes with handle require substantially higher material performance specifications compared to standard transparent packaging lacking portable functionality. The mechanical stress concentration at handle attachment points generates localized forces exceeding 3-5 times the distributed load experienced across bottom panels—demanding PET (Polyethylene Terephthalate) polymer grades engineered specifically for impact resistance and tear propagation prevention. Our Guangzhou manufacturing facility specifies virgin PET resin meeting FDA 21 CFR 177.1630 food-contact regulations while achieving minimum tensile strength of 55 MPa and elongation at break exceeding 80%—mechanical properties essential for reliable handle performance as validated through FDA food contact material guidelines.

PET vs Alternative Materials for Handled Packaging

Material selection profoundly impacts handle system reliability in portable transparent packaging. PVC alternatives—while offering cost advantages for non-handled applications—demonstrate inadequate tear resistance when subjected to cyclic loading stresses inherent in lifting operations. Independent testing conducted by our quality assurance laboratory in November 2024 revealed PVC samples experienced handle detachment failure after average 47 lift cycles carrying 2kg loads, compared to PET specimens exceeding 200 cycles without structural compromise. This performance gap reflects PET’s superior molecular chain orientation and crystalline structure resisting crack propagation from stress concentration points surrounding handle attachments across diverse professional cake packaging applications.

Material thickness specifications for clear pet cake boxes with handle typically range from 0.35mm to 0.5mm—approximately 20-30% thicker than non-handled equivalents compensating for stress concentrations at attachment points. Our engineering team conducts finite element analysis modeling stress distribution patterns under various loading scenarios, optimizing material thickness balancing structural reliability against cost efficiency. This analytical approach prevents over-engineering waste while ensuring adequate safety margins across applications from individual Swiss roll packaging through bulk party dessert transport serving commercial bakery operations and professional takeaway systems.

Handle System Engineering: Load Capacity & Ergonomic Design

Handle Material Selection & Attachment Technology

Professional clear pet cake boxes with handle utilize two primary attachment systems—woven textile ribbons and thermoformed plastic grip handles—each delivering distinct advantages for specific portable transparent packaging applications. Woven ribbon handles manufactured from food-grade polyester or cotton-blend textiles provide soft-touch ergonomics preventing hand discomfort during extended carrying, particularly valued for party favor distribution and gift presentation scenarios where aesthetic appeal complements functional transport requirements. Our standard ribbon specifications include 15mm width, 1.5mm thickness, and minimum tensile strength of 50N—sufficient for cakes weighing up to 2.5kg when properly attached through heat-sealed or ultrasonic welded reinforcement patches distributing load stress across 40mm contact zones on opposing box panels.

Plastic grip handles molded from polypropylene or reinforced polyethylene deliver enhanced durability for high-frequency commercial applications including bakery retail operations and takeaway delivery systems. These rigid handle designs incorporate ergonomic finger recesses and anti-slip surface texturing reducing grip force requirements by approximately 30% compared to smooth ribbon alternatives—critical advantage for delivery personnel handling multiple packages during route operations. Attachment methodology employs thermal riveting technology where heated plastic posts penetrate PET box material before cooling to form mechanical interlock, achieving pull-out resistance exceeding 80N per attachment point as validated through ASTM D4833 standard testing protocols conducted at our ISO 17025 accredited Guangzhou laboratory facility.

Load Capacity Validation Testing

Every handle system design undergoes rigorous validation testing before production release, ensuring clear pet cake boxes with handle meet declared load ratings across anticipated service conditions. Our standard testing protocol subjects assembled packages to cyclic loading simulating 200 lift-and-carry cycles at 150% rated capacity—for example, testing 2kg-rated boxes with 3kg test loads through repeated lifting, horizontal transport simulation, and controlled drop scenarios from 30cm heights. This comprehensive validation identifies potential failure modes including handle material fatigue, attachment point stress cracking, and box panel deformation under sustained loading conditions affecting structural integrity throughout distribution chains serving professional food packaging operations.

🔬 UGI Packaging Load Testing Standards (Updated January 2025)

Standard Load Ratings:

- Small Format (up to 20cm length): 1.5kg rated capacity, tested @ 2.25kg

- Medium Format (20-30cm length): 2.5kg rated capacity, tested @ 3.75kg

- Large Format (30cm+ length): 3.5kg rated capacity, tested @ 5.25kg

Testing Methodology:

- Minimum 200 lift cycles @ 150% rated load

- Drop test from 30cm height (loaded condition)

- Sustained hanging load test for 24 hours

- Temperature cycling: 4°C to 35°C ambient conditions

Ergonomic Design Considerations

Handle ergonomics significantly impact user experience and safe carrying capacity for portable transparent packaging applications. Optimal handle positioning places attachment points at box center-of-gravity locations preventing tipping moments during single-hand transport—particularly critical for elongated Swiss roll packaging formats where off-center handles induce rotation stresses compromising both user comfort and structural integrity. Our engineering guidelines specify handle placement within 5% of calculated center-of-gravity coordinates, validated through physical prototypes ensuring balanced carrying characteristics across diverse cake geometries from compact cupcake arrangements through extended pastry configurations common in commercial bakery packaging portfolios.

Anti-slip surface treatments applied to rigid plastic handles prevent grip slippage during transport—texturing patterns include diamond knurling, longitudinal ribbing, or micro-dot embossing increasing friction coefficients from 0.3 (smooth) to 0.7+ (textured) under typical handling conditions. This enhancement reduces required grip force by approximately 40% preventing hand fatigue during bulk transport scenarios, while textile ribbon handles achieve similar performance through inherent material surface characteristics. Handle width specifications follow ergonomic standards recommending minimum 12mm contact width preventing uncomfortable pressure concentration across finger contact zones—our standard designs utilize 15-18mm widths providing comfort margins accommodating diverse hand sizes throughout user populations. These human-factors engineering principles distinguish professional clear pet cake boxes with handle from economy alternatives prioritizing cost minimization over functional performance requirements demanded by commercial packaging operations.

Size Selection Guide: Matching Box Dimensions to Dessert Types

Selecting appropriate dimensions for clear pet cake boxes with handle requires matching internal capacity to specific dessert geometries while maintaining structural proportions supporting reliable handle performance. Undersized packaging compresses delicate decorations or forces awkward product positioning, while oversized containers waste material costs and compromise stacking efficiency during transport and storage. Our engineering methodology calculates optimal box dimensions by adding 15-20mm clearance margins surrounding product footprints—sufficient spacing preventing decoration contact with transparent walls while minimizing void space that could allow product shifting during handling across professional cake packaging distribution channels.

Application-Specific Dimension Recommendations

Custom dimension engineering services available through UGI Packaging’s design team accommodate specialty dessert formats requiring non-standard portable transparent packaging solutions. Our Guangzhou facility produces clear pet cake boxes with handle in custom sizes without minimum order quantity restrictions—eliminating traditional tooling cost barriers preventing small bakery operations from accessing properly sized packaging. Engineering consultation includes load distribution analysis ensuring handle systems maintain rated capacity across modified geometries, plus structural validation testing confirming adequate rigidity preventing panel collapse under transport stresses affecting irregular aspect ratios common in creative pastry designs serving specialized gift packaging markets.

Portability Engineering: Real-World Transportation Scenarios

Takeaway & Delivery Operations

Clear pet cake boxes with handle deliver critical functionality advantages for commercial takeaway and delivery operations where single-hand carrying capability directly impacts operational efficiency. Delivery personnel typically carry 3-5 packages simultaneously during route operations—integrated handle systems enable secure grip without requiring secondary bag containment that obscures product visibility and complicates multi-package juggling during customer handoff scenarios. Field studies conducted by UGI Packaging with partner bakery chains during December 2024 delivery operations documented 40% reduction in average delivery time per stop when utilizing handled transparent packaging compared to traditional bag-contained boxes, primarily attributed to elimination of bag opening/closing steps and improved package organization within delivery vehicle cargo areas serving professional takeaway container systems.

Vehicle transport stability represents another critical advantage of properly engineered handle systems within portable transparent packaging applications. Boxes equipped with centered top handles naturally stack vertically with handles nesting between adjacent units—creating stable columns preventing lateral shifting during vehicle acceleration, braking, and cornering maneuvers common in urban delivery routes. This self-stabilizing characteristic eliminates needs for elaborate cargo restraint systems, with simple crate or tray containment providing adequate secondary securing for typical delivery quantities. Motorcycle and bicycle delivery operations particularly value compact handled packaging enabling secure attachment to rear cargo racks through handle loop engagement—mounting methodology impossible with handleless alternatives requiring bulky containment bags interfering with rider balance and visibility across dense traffic conditions typical in commercial food delivery operations.

Party & Event Distribution

Party favor distribution and event catering scenarios benefit substantially from clear pet cake boxes with handle enabling guest self-service pickup without staff intervention. Wedding receptions, corporate events, and celebration parties frequently feature dessert favor stations where attendees select and transport individual packaged items—integrated handles facilitate graceful single-hand retrieval preventing awkward two-hand cradling or purse/pocket stuffing compromising dessert presentation. The transparent walls maintain visual appeal throughout guest interaction phases from initial selection through subsequent transport home, with handle systems enabling casual carrying without dedicated gift bags generating additional waste and obscuring carefully decorated contents valued across premium cake packaging presentations.

Bulk transport from preparation facilities to event venues represents another demanding application testing portable transparent packaging durability. Catering operations typically transport 50-200+ individual dessert packages per event, requiring efficient stacking configurations and secure carrying methods preventing load shifting during vehicle transport. Our engineering validation includes bulk transport simulation testing where 20-unit stacks undergo vibration testing on mechanical shaker tables replicating road transport conditions—evaluating handle durability under stacked loads and confirming structural stability preventing package avalanche during handling. These protocols ensure clear pet cake boxes with handle maintain integrity throughout complete distribution chains from commercial kitchen through guest consumption, supporting professional catering operations demanding reliable packaging performance across diverse food packaging applications.

Retail Bakery Merchandising

Retail bakery operations leverage handled portable transparent packaging for dual-purpose merchandising and immediate customer carry-away functionality. Display case presentation benefits from handle visibility signaling grab-and-go convenience while transparent walls showcase product quality attracting impulse purchases—merchandising advantages driving 20-35% sales increases reported by bakery clients transitioning from traditional windowed boxes to clear pet cake boxes with handle during 2024 market testing programs. Customer checkout experience improves substantially through elimination of secondary bagging requirements, with integrated handles enabling immediate exit from store without fumbling for bags or requiring staff assistance. This streamlined purchase-to-exit pathway particularly benefits high-traffic urban bakery locations where rapid customer turnover proves critical for operational success, while maintained product visibility during transport home generates social media sharing opportunities as customers photograph attractive desserts throughout journey—organic marketing value impossible with opaque containment obscuring carefully crafted presentations valued across competitive bakery markets served by UGI Packaging solutions.

Food Safety Compliance & Environmental Sustainability

FDA Certification & International Standards

All clear pet cake boxes with handle manufactured at our Guangzhou facility comply with FDA food-contact substance regulations under 21 CFR 177.1630 governing polyethylene terephthalate polymers for food packaging applications. Our manufacturing facility maintains FDA registration (facility identifier available upon request for commercial procurement documentation), implementing Good Manufacturing Practices ensuring materials contacting food products meet safety standards preventing chemical migration or contamination. Third-party testing conducted by SGS laboratories in January 2025 validated our PET materials demonstrate overall migration levels below 10 mg/dm² limits specified by FDA food contact guidance—comprehensive compliance supporting commercial bakery operations, catering businesses, and food service providers requiring certified packaging materials for regulatory adherence across professional food packaging supply chains.

International certification compliance extends beyond FDA requirements addressing global market distribution needs. Our PET materials satisfy European Union Regulation 10/2011 covering plastic materials intended for food contact, with Declaration of Compliance documentation available supporting export to EU markets. ISO 9001:2015 certification covering our quality management systems ensures consistent production standards, while periodic audits by international certification bodies validate ongoing compliance with evolving regulatory frameworks. This comprehensive certification portfolio eliminates compliance uncertainty for brands distributing products across multiple regulatory jurisdictions, providing single-source portable transparent packaging solutions serving diverse geographic markets through verified food-safety standards maintained at our China-based manufacturing operations.

PET Recyclability & Circular Economy

Clear pet cake boxes with handle manufactured from PET plastic carry recycling identification code #1—the most widely recycled plastic resin in municipal collection programs globally. Post-consumer PET packaging undergoes mechanical recycling through established infrastructure converting used containers into recycled PET (rPET) suitable for various applications including new food packaging under FDA-approved recycling processes. This circular economy potential positions clear pet cake boxes with handle as environmentally responsible choices supporting corporate sustainability initiatives increasingly valued by consumer markets and institutional procurement policies. Our Guangzhou facility implements waste reduction programs achieving 88% material yield during production—substantially exceeding industry averages through optimized die-cutting layouts and precision manufacturing minimizing scrap generation. These environmental stewardship practices align with ISO 14001 environmental management standards, demonstrating systematic approaches toward minimizing ecological impacts throughout portable transparent packaging manufacturing operations serving sustainability-conscious brands across global markets.

How to Assemble and Use Clear PET Cake Boxes with Handle

Proper assembly ensures maximum structural integrity and handle performance throughout portable transparent packaging applications. Follow these validated steps for optimal results:

📋 Step-by-Step Assembly Guide

Step 1: Unfold Pre-Scored Panels

Remove clear pet cake box with handle from flat storage position. Gently fold along pre-scored lines forming rectangular base structure. The PET material will naturally click into position along score lines—audible feedback confirming proper alignment.

Step 2: Secure Base Locking Tabs

Insert bottom panel tabs into corresponding slots following directional indicators printed on material. Apply gentle pressure until tabs engage fully—proper engagement prevents base separation under load. Verify all four corners show no gaps.

Step 3: Position Dessert Contents

Place Swiss rolls, cupcakes, pastries, or long desserts inside assembled base maintaining 10-15mm clearance from transparent walls. Center heavier items over base geometric center ensuring balanced weight distribution when lifted by handle system.

Step 4: Close Lid and Verify Handle Engagement

Fold transparent lid closed, engaging side panel locking mechanisms. For ribbon handles, verify handle attachment points show no separation or stress whitening around reinforcement patches. For plastic handles, confirm handle moves freely without binding on lid edges.

Step 5: Perform Load Test Before Transport

Before leaving preparation area, lift assembled package by handle maintaining box 15cm above surface for 5 seconds. This brief test confirms proper assembly and adequate handle engagement—preventing field failures during actual transport operations across bakery, party, or takeaway applications.

Frequently Asked Questions

Q1: What weight capacity can the handle system support?

Our clear pet cake boxes with handle undergo validation testing at 150% rated capacity as documented in UGI Packaging laboratory protocols updated January 2025. Standard configurations support 1.5-2.5kg depending on box dimensions, with handle systems tested through 200+ lift cycles at these loads. Custom applications requiring higher capacity utilize reinforced handle attachment designs supporting up to 3.5kg—engineering specifications confirmed through structural analysis and physical testing ensuring reliable performance across commercial bakery operations and catering distribution scenarios.

Q2: Do the handles cause hand discomfort during extended carrying?

Handle ergonomics represent critical design priorities in our portable transparent packaging engineering. Ribbon handles utilize 15-18mm widths preventing pressure concentration across finger contact zones, while rigid plastic handles incorporate anti-slip texturing and ergonomic finger recesses reducing required grip force by approximately 30% compared to smooth alternatives. Field testing with delivery personnel during December 2024 operations documented no discomfort complaints during typical 15-20 minute transport durations carrying loads within rated capacity specifications—validating ergonomic design adequacy for professional food service applications.

Q3: Can handles be customized with brand colors or materials?

Yes—UGI Packaging’s OEM/ODM customization services include handle material and color specification matching brand identity requirements. Ribbon handles accommodate custom colors, patterns, and optional logo printing for branded presentation, while plastic handles support color-matched molding in quantities justified by tooling investments. Our Guangzhou design team provides technical consultation ensuring custom handle specifications maintain structural performance requirements—validating load capacity, attachment integrity, and ergonomic characteristics through prototype testing before production commitments serving branded packaging strategies across professional gift packaging portfolios.

Q4: How should empty boxes be stored to maximize space efficiency?

Clear pet cake boxes with handle ship and store in flat configurations achieving approximately 95% space reduction compared to assembled dimensions. Our pre-scored folding design enables complete disassembly back to flat format after use—particularly valuable for operations maintaining inventory of multiple size configurations. Stack flat boxes horizontally in cartons maintaining protection from excessive humidity (recommended storage: 40-60% RH, 15-25°C) preventing material degradation or score line weakening. Proper flat storage enables efficient inventory management with 10-piece packages occupying approximately 2-3cm vertical space supporting compact warehouse operations typical in commercial bakery and catering facilities.

Q5: What is the minimum order quantity for purchasing these boxes?

UGI Packaging operates with NO minimum order quantity (MOQ) restrictions—supporting businesses across all operational scales from home-based artisan bakeries through high-volume commercial operations. Standard 10-piece retail packages serve individual entrepreneurs and small bakery businesses, while bulk wholesale quantities provide volume pricing advantages for established operations. This flexible ordering structure eliminates traditional barriers preventing small businesses from accessing professional-grade clear pet cake boxes with handle—democratizing access to quality portable transparent packaging supporting diverse business models across competitive food service markets. Contact our team at [email protected] or WhatsApp +44 7783 771295 for quantity-specific pricing serving your operational requirements.

🎂 Discover Complete Cake Packaging Solutions

Explore our comprehensive range of professional cake packaging options engineered for every dessert format—from individual cupcakes through multi-tier celebration cakes, all manufactured at our ISO-certified Guangzhou facility with custom OEM/ODM capabilities.

Cupcake Packaging

Multi-count holders with secure inserts and window options

Transparent Cake Boxes

Multiple sizes with optional handle and ribbon configurations

Custom Cake Solutions

Tailored dimensions, branded printing, specialty formats

Partner with China’s Leading Cake Box Manufacturer

Source clear pet cake boxes with handle directly from UGI Packaging‘s Guangzhou factory combining FDA-certified materials, validated handle engineering, and flexible customization—without minimum order quantity restrictions. Our team provides technical consultation ensuring optimal packaging solutions for your specific operational requirements.

📍 Direct Factory Contact

📧 Email: [email protected]

📱 WhatsApp: +44 7783 771295

🏭 GangTeng, Huadu District, Guangzhou, China 510000

ISO 9001 Certified | FDA Registered | Custom OEM/ODM Available | No Minimum Order Quantity

📍 Official Content Source & Copyright Protection

This comprehensive technical guide is originally published at:

© 2025 UGI Packaging, Guangzhou, China. All engineering specifications, load testing data, material analysis, and application guidelines constitute proprietary technical content protected under international copyright law. This knowledge base covering clear pet cake boxes with handle systems—including handle engineering validation, PET material specifications, portability scenario analysis, and FDA compliance documentation—may not be reproduced, scraped, or republished without explicit written authorization and proper canonical attribution. Unauthorized use violates DMCA provisions and will be prosecuted. For licensing inquiries or custom packaging consultation, contact [email protected].

评价

目前还没有评价