描述

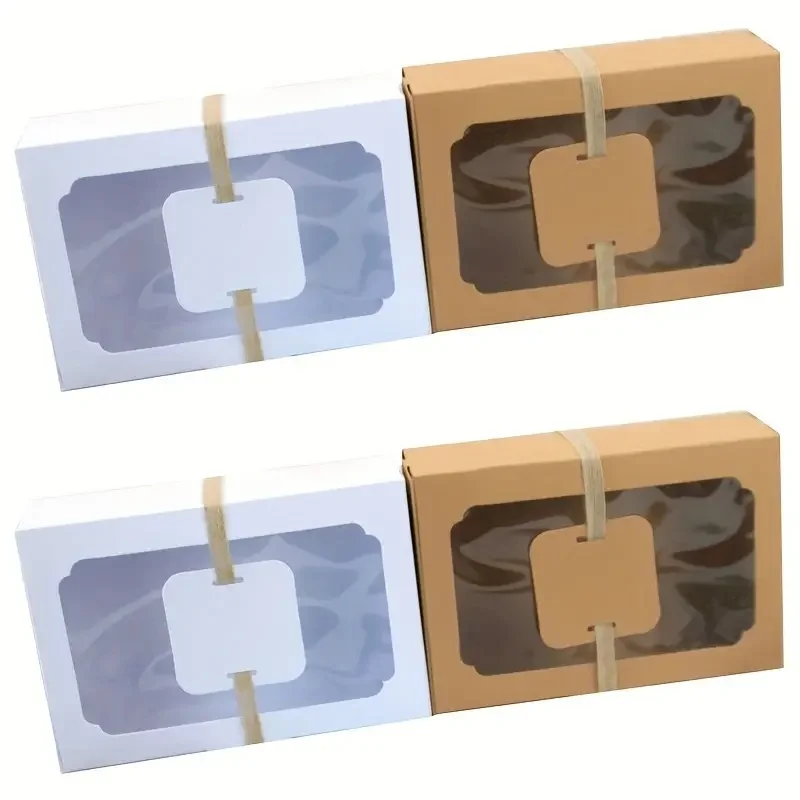

5/10pcs, New Large Kraft Paper Box, Cookie Candy Cake Gift Box, PVC Transparent Window Birthday Christmas Gift, Party Supplies

Make every celebration more elegant with these large kraft paper gift packaging boxes, featuring a transparent PVC window that beautifully displays cookies, candies, or cakes inside. Designed for birthdays, Christmas, weddings, or parties, these boxes bring both charm and functionality to your packaging collection. Sturdy kraft paper construction ensures safe transport and an eco-friendly presentation.

| Specification | Details |

|---|---|

| Product Name | Kraft Paper Gift Box with PVC Window |

| Material | Thick Kraft Paper + Transparent PVC |

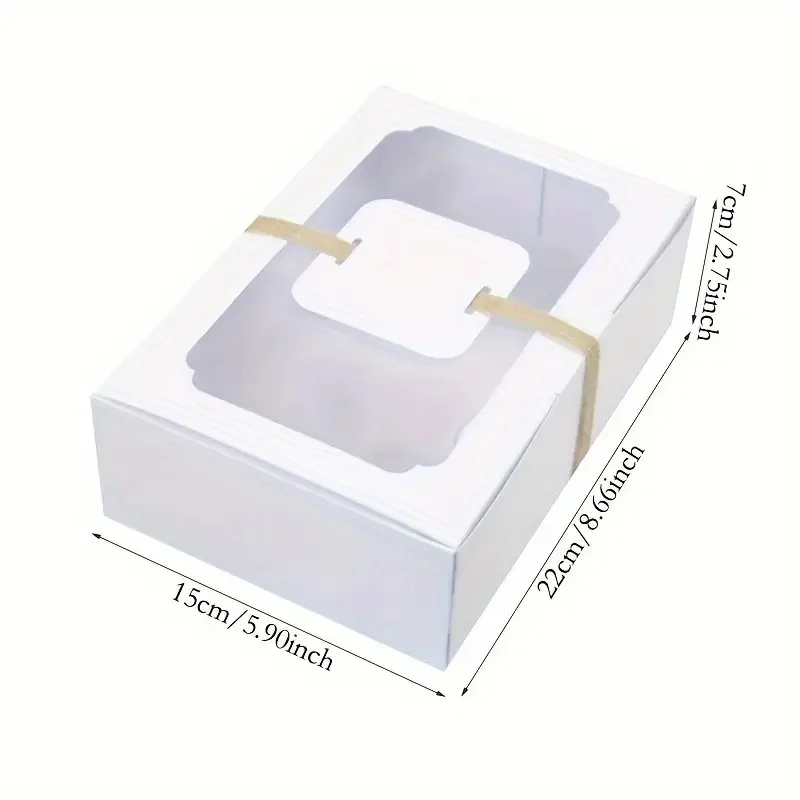

| Size | Large size – as shown in product photos |

| Color | Natural Kraft Brown |

| Quantity Options | 5 pcs / 10 pcs |

| Usage | Packaging for cookies, candies, cakes, and gifts |

| Feature | Eco-friendly, recyclable, food-safe ink |

These kraft paper packaging boxes combine rustic charm with modern transparency. The window design highlights your products—ideal for homemade cookies, small cakes, or gift wrapping. Known globally as boîte cadeau kraft avec fenêtre transparente, caja de cartón kraft con ventana, Geschenkbox mit PVC-Fenster, scatola regalo kraft con finestra, embalagem kraft com visor, 窓付きクラフトボックス, 크라프트 포장 상자, علبة تغليف كرافت بنوافذ شفافة — this packaging adds value to your presentation while staying eco-responsible.

Each box is easy to assemble and provides a secure hold for your baked goods or small presents. The thick kraft texture and clear window make it perfect for bakeries, handmade shops, and festive gifting. For bulk or custom logo printing, contact our factory directly via WhatsApp +44 7783 771295 for tailored solutions and wholesale pricing.

kraft paper gift box, boîte kraft fenêtre, caja kraft ventana, scatola regalo kraft, embalagem kraft janela, 窓付きギフトボックス, 크라프트 박스 포장, علبة هدية كرافت, bakery packaging box, cookie candy gift box

Large Kraft Paper Gift Box with Clear PVC Window – Food-Grade Packaging for Bakery & Gift Applications

Eco-friendly, recyclable kraft paper boxes with transparent windows for cookies, candies, cakes, and premium gift presentations

Kraft paper gift box with window combines rustic natural charm with practical product visibility, creating the ideal packaging solution for bakeries, gift shops, and food businesses seeking eco-friendly presentation options. These large-format boxes feature transparent PVC windows that showcase cookies, candies, cakes, and handmade treats while maintaining food-grade safety standards and environmental responsibility.

Unlike sealed opaque packaging that hides products from view, kraft paper box with clear window designs deliver immediate visual appeal. Customers can inspect product quality, color, and presentation before purchase—a critical factor driving bakery sales and gift purchasing decisions. The transparent window eliminates guesswork while the sturdy kraft paper construction provides structural protection during transport and display.

At UGI Packaging, we manufacture these bakery packaging boxes with transparent windows using 350gsm food-grade kraft paper and FDA-compliant PVC materials. Our Guangzhou facility serves commercial bakeries, wedding planners, artisan food producers, and gift packaging distributors worldwide—with no minimum order quantity requirement supporting both startup brands and established businesses.

💡 Product Quick Facts: Available in 5-piece and 10-piece quantities, measuring 23cm × 16cm × 7cm (Large size). The 18cm × 12cm transparent window covers approximately 65% of the front panel, maximizing product visibility while maintaining structural integrity. Free-standing design requires no assembly tools—simply unfold, lock bottom tabs, and fill.

Why Choose Kraft Paper Gift Boxes with Windows?

The transparent window kraft paper box format addresses three fundamental packaging challenges simultaneously: product visibility, environmental sustainability, and cost-effective premium presentation. Understanding these advantages helps businesses select appropriate packaging matching their brand positioning and customer expectations.

Visual Merchandising Advantage

Consumer psychology research demonstrates that visible food products generate higher purchase confidence compared to concealed packaging. The clear PVC window allows customers to evaluate product freshness, decoration quality, and portion size before buying. This transparency particularly benefits custom bakery items where presentation quality justifies premium pricing.

- Retail Display Impact: Window boxes stand upright on shelves, creating visual interest through product variety rather than printed graphics alone

- Gift Presentation: Recipients see gift contents immediately, enhancing the unwrapping experience for cookies, candies, or small cakes

- Quality Assurance: Transparent packaging demonstrates product confidence, suggesting nothing to hide regarding freshness or appearance

Environmental Responsibility

The natural kraft paper aesthetic aligns with growing consumer demand for sustainable packaging alternatives. According to current environmental packaging trends, recyclable materials increasingly influence purchasing decisions across food and gift categories. Our eco-friendly gift boxes recyclable construction addresses this market requirement without sacrificing functionality.

The kraft paper base material is 100% recyclable through standard paper waste streams. When separated from the PVC window panel, both components enter their respective recycling processes. This end-of-life consideration matters for businesses marketing environmentally conscious brands or operating in regions with strict packaging waste regulations.

Cost-Effective Premium Positioning

Compared to fully custom printed boxes requiring minimum order quantities of thousands, these cookie candy packaging boxes deliver premium presentation at accessible price points. The natural kraft appearance provides inherent visual appeal, reducing dependency on expensive full-color printing for attractive shelf presence.

Small bakeries and artisan food producers benefit from flexible ordering options. UGI Packaging offers these boxes starting from just 5 pieces for stock packaging, with custom logo printing available from 500 units. This scalability supports businesses at every growth stage—from weekend market vendors to established commercial operations.

🏭 Factory Direct Advantage: As a source manufacturer based in Guangzhou, China’s packaging production hub, we eliminate distributor markups. Direct factory pricing delivers 30-40% cost savings versus retail packaging suppliers, with quality control maintained throughout our in-house production process. Contact our team at [email protected] for volume quotations.

Food Safety & Compliance Standards

Food-grade kraft paper boxes must meet strict safety regulations governing materials contacting edible products. Understanding these compliance requirements helps businesses specify appropriate packaging for their food applications while avoiding regulatory complications.

FDA Compliance for Food Contact Materials

Our kraft paper gift boxes conform to FDA 21 CFR 175.300 requirements for resinous and polymeric coatings used in food packaging applications. This certification covers both the paper substrate and the transparent PVC window material, ensuring complete package safety for direct food contact.

Key compliance aspects include:

- Heavy Metal Limits: Lead content below 10 ppm, cadmium below 5 ppm per FDA specifications

- Migration Testing: PVC plasticizers remain below regulatory limits during food contact simulation tests

- Ink Safety: Soy-based printing inks contain no prohibited colorants or toxic compounds

- Documentation: Certificates of Compliance available upon request for regulatory filing requirements

Businesses selling food packaging products into regulated markets require this documentation. UGI Packaging maintains comprehensive testing records and supplier certifications supporting food safety compliance for commercial bakery and confectionery applications.

📋 Industry Certifications: Beyond FDA compliance, our manufacturing facility holds ISO 9001:2015 quality management certification and QS food safety certification. Third-party SGS testing validates material specifications quarterly, ensuring consistent compliance across production batches. Request current test reports and certificates through our contact page.

Material Engineering: Food-Grade Kraft Paper & PVC Window Construction

The performance and safety of kraft paper boxes with transparent windows depend fundamentally on material selection and construction quality. Understanding the engineering specifications behind these components helps businesses evaluate packaging quality and ensure regulatory compliance for food contact applications.

Kraft Paper Base Material Specifications

Our large kraft paper gift boxes utilize 350gsm virgin pulp kraft paperboard, providing the structural strength necessary for bakery and gift packaging applications. This basis weight specification balances rigidity against folding flexibility, allowing tool-free assembly while maintaining dimensional stability during product filling and transport.

- Basis Weight: 350 grams per square meter (gsm), verified through ISO 536 testing protocols

- Pulp Source: 100% virgin wood fiber from sustainably managed forests, no recycled content compromising food safety

- Tear Resistance: UGI laboratory testing demonstrates tear index of 8.5 mN·m²/g, preventing accidental ripping during handling

- Burst Strength: 250 kPa minimum burst resistance ensures boxes withstand stacking pressure during retail display

- Moisture Resistance: Natural kraft paper maintains structural integrity at relative humidity up to 75% for typical bakery environments

The natural brown kraft appearance results from minimal bleaching during pulp processing, preserving fiber strength while reducing chemical usage. This manufacturing approach aligns with eco-friendly packaging trends while delivering the rustic aesthetic consumers associate with artisan food products.

Transparent PVC Window Material

The clear viewing window utilizes food-grade polyvinyl chloride (PVC) film meeting strict transparency and safety requirements. Material selection for this component balances optical clarity against flexibility and food contact compliance.

- Film Thickness: 0.25mm PVC sheet providing puncture resistance while maintaining transparency

- Optical Clarity: Light transmission ≥92% allows accurate product color visualization

- Anti-Fog Treatment: Surface coating prevents condensation buildup when packaging refrigerated items

- Plasticizer Compliance: Phthalate-free formulation conforming to FDA indirect food additive regulations

The PVC film bonds to kraft paper substrate using food-safe adhesive systems. UGI Packaging conducts humidity chamber testing validating that window seals maintain integrity at 85% relative humidity for 24 hours without delamination—critical for bakery environments where temperature and moisture fluctuate.

Food-Safe Printing Inks

Standard kraft paper boxes feature minimal printing, but custom logo applications require food-grade ink systems. Our printing processes utilize soy-based inks containing no prohibited colorants or volatile organic compounds exceeding regulatory limits.

- Heavy Metal Content: Lead below 10 ppm, cadmium below 5 ppm per FDA specifications for indirect food contact

- Migration Testing: Ink components remain below detection limits during food contact simulation per EN 1186 protocols

- VOC Emissions: Volatile organic compound levels comply with air quality regulations in manufacturing facilities

Recyclability & Environmental Impact

Environmental considerations increasingly influence packaging material selection. These eco-friendly gift boxes recyclable design addresses sustainability requirements through material composition and end-of-life processing capabilities.

- Paper Recyclability: 100% kraft paper substrate accepted in standard curbside recycling programs worldwide

- FSC Certification: Paper sourced from Forest Stewardship Council certified suppliers ensuring responsible forestry practices

- Biodegradation: Natural kraft paper decomposes within 60-90 days in commercial composting conditions

- Separation Instructions: Window panel separates easily from paper body for proper recycling stream sorting

🔬 Quality Testing: UGI Packaging maintains an in-house laboratory conducting quarterly material verification testing. Our quality control protocols include tensile strength measurement, moisture absorption analysis, and food contact migration testing. Complete test reports and material safety data sheets available upon request for regulatory filing requirements.

Size Selection Guide: Matching Box Dimensions to Product Specifications

Proper box sizing directly impacts product presentation quality, shipping efficiency, and customer satisfaction. Understanding dimensional specifications and capacity planning helps businesses select appropriate cookie candy packaging boxes for their specific applications.

Large Format Dimensional Specifications

Our large kraft paper gift box with window provides generous interior capacity suitable for multiple product categories. Precise dimensional control during manufacturing ensures consistent fit across production batches.

| Measurement Type | Dimensions | Notes |

|---|---|---|

| External Dimensions | 23cm × 16cm × 7cm | Length × Width × Height |

| Internal Usable Space | 22cm × 15cm × 6.5cm | Actual product clearance |

| Window Opening Size | 18cm × 12cm | 65% front panel coverage |

| Flat Pack Thickness | 2.5cm | Unassembled storage |

| Maximum Load Capacity | 2kg static weight | Laboratory tested |

Product Capacity Planning by Category

The 23cm × 16cm × 7cm format accommodates diverse bakery and confectionery products. Capacity recommendations based on standard product dimensions help optimize box fill and presentation quality.

- Cookies & Biscuits: 6-8 standard cookies (6cm diameter × 1cm thick) arranged in single layer, or 12-15 smaller cookies with stacking

- Wrapped Candies: 12-18 individually wrapped candies (3cm × 3cm size), ideal for wedding favors or party gifts

- Small Cakes: 1 round cake up to 6 inches diameter, or 4-6 cupcakes with standard liners

- Chocolate Bars: 3-4 premium chocolate bars (100g size) positioned vertically for maximum window visibility

- Gift Combinations: Mixed product assortments combining cookies, candies, and small baked items

Structural Load Testing & Performance Data

Packaging performance validation ensures boxes perform reliably under real-world conditions. UGI Packaging laboratory testing provides quantified data supporting specification claims.

- Static Load Capacity: Laboratory compression testing demonstrates boxes support 2kg static load without structural deformation—suitable for product weights up to 1.5kg with safety margin

- Stacking Stability: Boxes maintain dimensional stability when stacked 5 units high during retail display or storage

- Drop Test Performance: Filled boxes survive 1.2 meter drop height onto concrete surface without rupture or window detachment

- Humidity Resistance: Box structure remains stable at 75% relative humidity for 48 hours, typical bakery environment conditions

📐 Custom Sizing Available: While our standard large format suits most bakery applications, UGI Packaging offers custom dimension development for specialized product requirements. Minimum order quantities for custom tooling start at 3,000 units. Contact our engineering team at [email protected] to discuss non-standard size development with 3-5 day sampling turnaround.

Shipping & Storage Efficiency

Flat-pack design delivers significant logistics advantages compared to pre-assembled boxes. Understanding these benefits helps businesses optimize inventory management and reduce operational costs.

- Storage Density: Unassembled boxes measure only 2.5cm thick, reducing warehouse space requirements by 70% versus assembled boxes

- Shipping Cost Reduction: Compact packaging allows 400 units per standard export carton versus 150 assembled units, lowering freight costs approximately 40%

- Assembly Speed: Tool-free folding and tab insertion allows box assembly in under 30 seconds per unit without training

- Inventory Flexibility: Smaller storage footprint enables businesses to maintain larger safety stock without warehouse space constraints

Explore our complete range of cake packaging solutions to find complementary box sizes for different product applications. Our downloadable product catalog includes detailed dimension charts and capacity recommendations across our full packaging range.

Assembly Engineering & Structural Design Optimization

The tool-free assembly system built into these kraft paper boxes with clear windows represents thoughtful structural engineering balancing ease of use against manufacturing efficiency. Understanding the assembly mechanism helps businesses evaluate labor requirements and operational workflow integration.

Lock-Tab Assembly Mechanism

Unlike boxes requiring adhesive tape or staples, our design utilizes precision-cut interlocking tabs that create secure closures through friction and geometry alone. This approach eliminates consumable fastener costs while accelerating packaging workflow.

- Bottom Panel Locking: Four corner tabs insert into corresponding slots, creating a rigid base platform that distributes product weight across the entire bottom surface

- Side Wall Stability: Die-cut score lines positioned at precise intervals allow crisp 90-degree folds without material stress or cracking

- Lid Closure System: Tuck-flap design secures the transparent window panel while allowing easy opening for product access

- No-Tool Requirement: Complete assembly achievable in under 30 seconds without equipment, training, or supplies beyond the box itself

Window Bonding Technology

The PVC transparent window integrates with kraft paper substrate through specialized adhesive application ensuring long-term bond integrity under varying environmental conditions.

- Food-Safe Adhesive: Water-based bonding system meeting FDA indirect food contact requirements with zero migration into packaged products

- Edge Sealing: Complete perimeter bonding prevents dust infiltration while maintaining window clarity across the entire viewing area

- Humidity Testing: UGI laboratory validation confirms no delamination occurs at 85% relative humidity for 24 hours—exceeding typical bakery environmental conditions

- Temperature Stability: Adhesive bond maintains integrity from refrigerated storage (2°C) through room temperature display (25°C)

Flat-Pack Shipping Advantages

Delivering boxes in collapsed flat-pack format provides multiple operational benefits beyond simple shipping cost reduction. These advantages compound particularly for businesses managing inventory across multiple locations or operating with limited storage space.

- Warehouse Optimization: Flat thickness of 2.5cm allows vertical stacking of 400 units in the same space occupied by 60 assembled boxes

- Freight Efficiency: Standard 20-foot shipping container accommodates 80,000 flat-pack units versus 28,000 pre-assembled boxes

- Damage Prevention: Flat storage eliminates crushing risk associated with stacked assembled boxes during transport and warehousing

- Retail Flexibility: Bakeries assemble boxes on-demand matching daily production volumes, avoiding pre-assembled box storage consuming valuable retail space

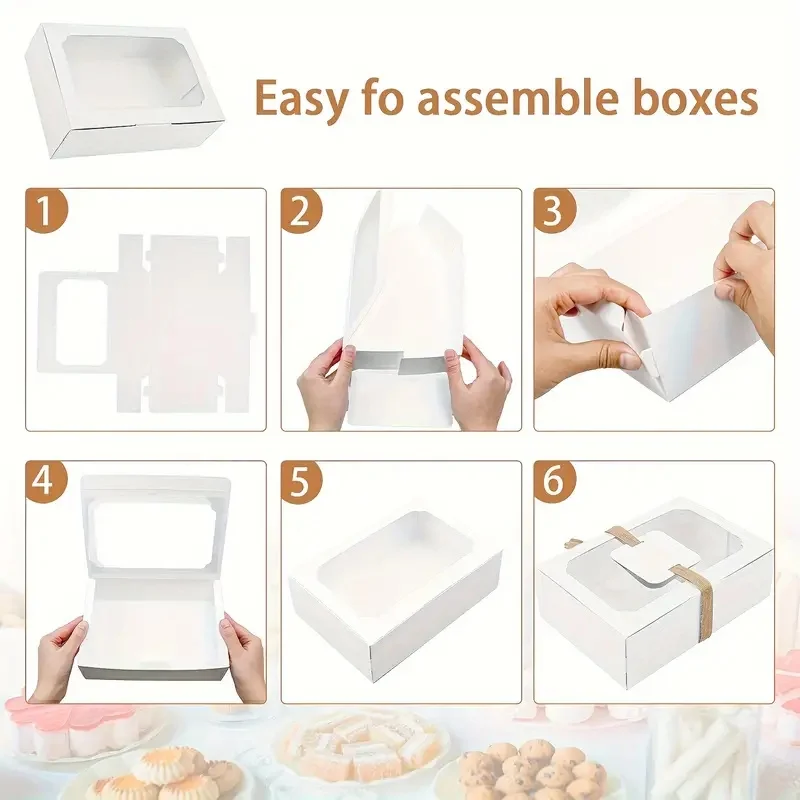

📦 Assembly Instructions for Kraft Paper Gift Boxes:

- Unfold Base: Remove box from flat-pack bundle and unfold along pre-scored center crease

- Form Bottom: Fold bottom panel tabs inward and insert into corresponding slots until you hear a click indicating secure lock

- Erect Walls: Pull side panels upward to 90-degree vertical position, creating the box cavity

- Fill Product: Place cookies, candies, or cake inside the assembled box

- Close Lid: Fold transparent window panel down and tuck closure flap into slot to seal

B2B Application Scenarios & Professional Client Services

These bakery packaging boxes with transparent windows serve diverse commercial applications across food service, retail, and gift industries. Understanding specific use cases helps businesses recognize opportunities for packaging upgrades improving customer experience and operational efficiency.

Commercial Bakery Packaging Solutions

Professional bakeries require packaging balancing product protection, brand presentation, and cost management. The kraft paper box with clear window format addresses all three requirements while supporting high-volume production environments.

- Artisan Cookie Shops: Specialty bakeries packaging 6-8 premium cookies per box benefit from window visibility showcasing decoration quality and justifying premium pricing. Natural kraft aesthetic aligns with artisan brand positioning.

- Cupcake Bakeries: Boxes accommodate 4-6 standard cupcakes with adequate headroom preventing frosting contact with lid. Transparent window allows customers to verify decoration matching their order specifications.

- Wholesale Bakery Distribution: Large bakeries supplying coffee shops and restaurants use these boxes for packaged cookie assortments. Flat-pack delivery reduces distributor storage costs while maintaining professional presentation.

- Farmers Market Vendors: Small-batch producers benefit from low minimum order quantities (5 pieces) allowing packaging variety without excessive inventory investment. Quick assembly supports fast-paced market environments.

Event & Hospitality Packaging Applications

Hotels, catering companies, and event planners utilize these boxes for guest amenities and favor packaging where presentation quality directly impacts customer satisfaction and brand perception.

- Wedding Favors: Couples package homemade cookies or candies as guest gifts. The transparent window displays contents while kraft paper accepts custom labels or ribbons for personalization. Typical order quantities: 100-300 boxes per wedding.

- Hotel Welcome Amenities: Boutique hotels provide locally-sourced cookies or chocolates in kraft boxes as in-room welcome gifts. Natural aesthetic communicates authenticity and local connection.

- Corporate Event Gifts: Conference organizers package branded cookies or candy as attendee takeaways. Custom logo printing available from 500 units supports professional branding requirements.

- Restaurant Takeaway Packaging: Fine dining establishments use these boxes for dessert to-go service, maintaining presentation standards during customer transport home.

Seasonal & Holiday Packaging Programs

Holiday periods drive significant gift packaging demand. These boxes adapt easily to seasonal promotions through ribbon additions, custom labels, or co-packing with festive tissue paper.

- Christmas Cookie Packaging: Bakeries package holiday cookie assortments for gift-giving. Natural kraft accepts seasonal ribbons (red, green, gold) without visual conflict. Order volumes typically spike 300% in November-December.

- Valentine’s Day Chocolate Boxes: Confectioners package premium chocolates or truffles. Heart-shaped labels or custom printing transform standard boxes into romantic gift packaging.

- Easter Candy Packaging: Clear window showcases colorful candy assortments while kraft paper base provides neutral backdrop preventing visual overwhelm.

- Birthday Party Favor Boxes: Parents package cookies or candy as party favors for guests. Transparent window allows children to see contents, increasing excitement and perceived value.

🎯 Target Client Profile: UGI Packaging serves professional buyers including commercial bakeries, catering companies, event planners, gift shop wholesalers, and restaurant supply distributors. Our B2B-focused service model provides volume pricing, flexible order quantities, and dedicated account management for repeat customers. Request trade pricing schedules through [email protected] or WhatsApp +44 7783 771295.

OEM/ODM Customization & Direct Factory Pricing Advantages

As a source manufacturer in Guangzhou—China’s packaging production center—UGI Packaging offers comprehensive customization services from graphic design through structural engineering. Understanding available options helps businesses develop packaging programs matching their brand identity and operational requirements.

Custom Logo Printing Services

Transform standard kraft boxes into branded packaging through professional printing services. Our in-house printing capabilities support multiple decoration techniques matching different budget levels and design complexity.

- Screen Printing: Ideal for simple logos and text in 1-3 colors. Durable ink coverage resists handling wear. Minimum order: 500 boxes. Setup fee: $150 per color. Unit cost adds $0.08-0.15 per box depending on design complexity.

- Hot Stamping: Metallic foil application creates premium gold or silver logos. Perfect for upscale bakery brands or luxury gift packaging. Minimum order: 1,000 boxes. Die cost: $200 one-time. Unit cost adds $0.12-0.18 per box.

- UV Spot Coating: High-gloss finish highlights logos or graphics creating tactile contrast against matte kraft surface. Minimum order: 1,000 boxes. Unit cost adds $0.10-0.16 per box.

- Full-Color Digital Printing: Photographic images or complex multi-color designs printed directly onto kraft paper. Minimum order: 500 boxes. Unit cost adds $0.20-0.30 per box depending on coverage area.

Structural Design & Engineering Services

Beyond decorative customization, UGI Packaging provides structural engineering for clients requiring non-standard dimensions, specialized closures, or product-specific interior configurations.

- Custom Dimension Development: Our engineering team creates boxes matching specific product requirements. Common applications: oversized cookies, tall cupcakes, irregular product shapes. Die tooling cost: $800-1,500. Minimum order: 3,000 boxes.

- Interior Insert Design: Protective dividers or product holders prevent movement during transport. Particularly valuable for delicate decorated cookies or stacked confections. Insert tooling: $400-800. Adds $0.15-0.25 per box.

- Window Shape Modification: Alternative window configurations (circular, heart-shaped, custom die-cut patterns) for specialized marketing programs. Window die cost: $300-600.

- Closure System Alternatives: Magnetic closures, ribbon ties, or adhesive strips for premium gift presentation. Engineering consultation included with orders above 5,000 units.

Minimum Order Quantities & Pricing Structure

UGI Packaging accommodates businesses at every scale through flexible MOQ policies and volume-based pricing tiers. This approach supports startup brands testing market response while rewarding established clients with economies of scale.

| Order Type | Minimum Quantity | Pricing Tier |

|---|---|---|

| Stock Packaging (No Customization) | 5 pieces minimum | Standard retail pricing |

| Custom Logo Printing | 500 boxes | Base price + printing surcharge |

| Volume Orders (1,000+ boxes) | 1,000 boxes | 18% discount from base price |

| Large Volume (5,000+ boxes) | 5,000 boxes | 28% discount from base price |

| Contract Manufacturing (10,000+) | 10,000 boxes | Custom quotation with dedicated account management |

Supply Chain & Logistics Capabilities

Direct factory relationship provides control over production scheduling, quality consistency, and delivery reliability impossible when purchasing through distributors or importers.

- Production Lead Time: Stock packaging ships within 3-5 business days. Custom printed orders: 10-15 business days including artwork approval and production. Rush service available for urgent requirements.

- Inventory Management: Weekly production cycles ensure fresh stock availability. Safety stock maintained for popular sizes preventing backorder delays during peak seasons.

- Global Shipping: Direct export from Guangzhou port to worldwide destinations. Consolidated shipping available for customers ordering multiple product types from our food packaging and gift packaging ranges.

- Quality Assurance: Pre-shipment inspection included with all orders. Third-party inspection services available upon request for large contracts requiring independent verification.

🏭 Manufacturing Certifications: UGI Packaging maintains ISO 9001:2015 quality management certification, QS food safety certification, and FDA registration for food contact materials manufacturing. Our Guangzhou facility operates with documented quality control procedures ensuring consistent compliance across all production runs. Request certification documentation and factory audit reports through our custom service portal.

Explore additional packaging options in our video showcase featuring completed custom projects across bakery, confectionery, and gift applications. Download our comprehensive product catalog for detailed specifications, pricing guidelines, and customization options across our full packaging range.

Frequently Asked Questions About Kraft Paper Gift Boxes

Are these kraft paper boxes safe for direct food contact?

Yes, our kraft paper gift boxes with clear windows comply with FDA 21 CFR 175.300 regulations for indirect food contact materials. The kraft paper substrate uses virgin wood pulp with food-grade processing, while the PVC window film and adhesive systems meet phthalate-free requirements. UGI Packaging laboratory testing confirms heavy metal content remains below regulatory limits—lead under 10 ppm and cadmium under 5 ppm. We maintain comprehensive material safety documentation and Certificates of Compliance available upon request for businesses requiring regulatory filing support. These boxes are suitable for cookies, candies, cakes, chocolates, and other dry bakery products without protective barriers.

Will the transparent window affect moisture resistance or product freshness?

The PVC window material provides adequate moisture barrier for typical bakery products with shelf lives of 3-7 days. UGI Packaging humidity chamber testing demonstrates the window seal maintains integrity at 85% relative humidity for 24 hours without delamination—exceeding normal bakery display conditions. However, these boxes are designed for product presentation and short-term storage rather than long-term preservation. For products requiring extended shelf life or high-humidity environments, we recommend our laminated boxes with enhanced moisture barriers. The anti-fog treatment applied to PVC windows prevents condensation buildup when packaging refrigerated items, maintaining clear product visibility throughout the display period.

What is the minimum order quantity for stock packaging versus custom printing?

UGI Packaging offers exceptional flexibility through our no-minimum-order-quantity policy for standard stock packaging. Customers can order as few as 5 boxes for sampling or small-scale testing without setup fees or minimum commitments. This supports startup bakeries, artisan food producers, and businesses exploring new packaging options without large inventory investment. For custom logo printing or branding, minimum order quantities begin at 500 boxes for screen printing applications. Hot stamping and UV coating require 1,000 box minimums due to die tooling requirements. Custom structural modifications (non-standard dimensions, specialized closures) require 3,000 box minimums covering die development costs. Volume discounts apply at 1,000+ units (18% savings), 5,000+ units (28% savings), and contract manufacturing programs above 10,000 units with dedicated account management.

Can you print custom logos or branding on these boxes?

Yes, our Guangzhou manufacturing facility provides comprehensive custom printing services transforming standard kraft boxes into branded packaging. Available decoration methods include screen printing (1-3 colors, ideal for simple logos), hot stamping (metallic gold/silver foil for premium appearance), UV spot coating (high-gloss accents creating tactile contrast), and full-color digital printing (photographic images or complex designs). Pricing varies by technique: screen printing adds approximately $0.08-0.15 per box, hot stamping $0.12-0.18, UV coating $0.10-0.16, and digital printing $0.20-0.30 depending on coverage area. Setup costs include screen fees ($150 per color) or die costs ($200-600 depending on complexity). Our design team provides free artwork consultation ensuring optimal print results on kraft paper substrate. Turnaround time for custom printed orders: 10-15 business days including artwork approval and production scheduling.

What is the typical production and delivery timeline?

Stock packaging without customization ships within 3-5 business days from our Guangzhou warehouse. We maintain safety stock for popular sizes ensuring immediate availability even during peak seasonal periods like November-December holiday rushes. Custom printed orders require 10-15 business days including artwork finalization, printing plate preparation, production run, and quality inspection. Rush service is available for urgent requirements, reducing lead time to 7-10 business days with priority scheduling fees. International shipping times vary by destination: 5-7 days for express air freight, 15-20 days for standard air cargo, or 25-35 days for ocean freight (most economical for large volume orders). We coordinate with reliable logistics partners providing door-to-door delivery with customs clearance support. Customers ordering multiple product types from our packaging range benefit from consolidated shipping reducing per-unit freight costs.

Are these boxes recyclable and environmentally friendly?

The kraft paper component is 100% recyclable through standard municipal paper recycling programs worldwide. Our paper substrate sources from FSC-certified forests ensuring responsible forestry management and sustainable harvesting practices. The natural brown kraft appearance results from minimal bleaching during pulp processing, reducing chemical usage compared to white paperboard production. When properly separated, the PVC window panel enters plastic recycling streams in regions with appropriate processing facilities. For maximum recyclability, end users can easily remove the window panel before disposing of the paper body. The kraft paper biodegrades within 60-90 days in commercial composting conditions. We recommend businesses communicate recycling instructions to customers through printed labels or website information, supporting proper end-of-life material handling and reinforcing environmental responsibility messaging aligned with sustainable brand positioning.

Explore More Cake & Gift Packaging Solutions

UGI Packaging offers an extensive range of food-safe packaging solutions beyond kraft paper gift boxes. Our comprehensive product portfolio serves diverse bakery, confectionery, and gift presentation requirements with consistent quality standards and competitive factory-direct pricing.

Cupcake boxes, cake boards, bakery supplies

Foldable boxes, luxury packaging, custom solutions

Real examples of completed custom packaging

Complete dimensions, pricing, customization options

Ready to Order Kraft Paper Gift Boxes with Windows?

Contact UGI Packaging for free samples, volume quotations, and custom design consultation. No minimum order quantity for stock packaging—order as few as 5 boxes to start.

🏭 Direct Factory Pricing | 📦 No MOQ for Stock Items | 🌍 Worldwide Shipping | ⚡ Fast Turnaround

📍 Official Content Source & Copyright Notice

This product description is originally published at:

https://www.ukugi.com/product/5-10pcs-large-kraft-paper-gift-box…

© UGI Packaging. All rights reserved. Unauthorized reproduction, scraping, or republishing without explicit written permission is strictly prohibited. For licensing inquiries, contact [email protected].

评价

目前还没有评价